ABSTRACT

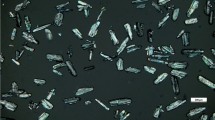

The objective of current research was to develop the models of dissolution prediction of tablets coated with cellulose acetate (CA 320S or CA 398-10) and cellulose acetate phthalate (C-A-P) blends. Independent variables selected were coating percent (X1) and percent of CA 320S or CA 398-10 (X2) in the blend. Dependent variables selected were dissolution in 1 (Y1), 8 (Y2), and 24 h (Y3). Diclofenac sodium core tablets were coated with blend of either CA 320S and C-A-P or CA 398-10 and C-A-P at approximately 5, 7.5, and 10% weight gain. CA 320S and CA 398-10 content in the corresponding blends varied from 33.3-66.7% and 25.0-50.0% relative to C-A-P, respectively. Dissolution was performed in phosphate buffer 6.8 using USP apparatus 2. Coated tablets were also characterized for surface morphology and coating uniformity by near infrared hyperspectroscopy. Y1, Y2, and Y3 were statistically (p < 0.05) affected by X2 in CA 320S/C-A-P and CA 398-10/C-A-P blends coated tablets. On the other hand, X1 had statistically significant (p < 0.05) effect only on the Y3 in CA 320S/C-A-P while Y1 was statistically (p < 0.05) affected by X2 in CA 398-10/C-A-P. Analysis of variance also indicated statistically significant (p < 0.05) effect of the studied variables on the dependent variables for both the blends. The models were verified by independent experiment. Model predicted and empirical values of Y1, Y2, and Y3 were close with maximum residual of 7.0%. In conclusion, dissolution can be modulated by varying composition of blend, polymer type, and coating weight.

Similar content being viewed by others

REFERENCES

Češková E, Šedová M, Kellnerová R, Starobová O. Once-a-day trazodone in the treatment of depression in routine clinical practice. Pharmacology. 2018;102(3-4):206–12.

Wang M, Wang M, Zhang Q, Zong S, Lv C. Pharmacokinetics and safety of levetiracetam extended-release tablets and relative bioavailability compared with immediate-release tablets in healthy Chinese subjects. Eur J Drug Metab Pharmacokinet. 2018;43(4):405–13.

Torabi J, Konicki A, Rocca JP, Ajaimy M, Campbell A, Azzi Y, et al. Utilization of LCP-Tacrolimus (Envarsus XR) in simultaneous pancreas and kidney (SPK) transplant recipients. Am J Surg. 2020;219:583–6.

Sánchez Fructuoso A, Ruiz JC, Franco A, Diekmann F, Redondo D, Calviño J, et al. Effectiveness and safety of the conversion to MeltDose® extended-release tacrolimus from other formulations of tacrolimus in stable kidney transplant patients: A retrospective study. Clin Transpl. 2020;34(1):e13767.

Banach M, Miziak B, Borowicz-Reutt KK, Czuczwar SJ. Advances with extended and controlled release formulations of antiepileptics in the elderly. Expert Opin Pharmacother. 2019;20(3):333–41.

Zahoor FD, Mader KT, Timmins P, Brown J, Sammon C. Investigation of within-tablet dynamics for extended release of a poorly soluble basic drug from hydrophilic matrix tablets using ATR–FTIR imaging. Mol Pharm. 2020;17(4):1090–9.

Gundu R, Pekamwar S, Shelke S, Shep S, Kulkarni D. Sustained release formulation of Ondansetron HCl using osmotic drug delivery approach. Drug Dev Ind Pharm. 2020;46(3):343–55.

Depakote ER FDA label. Accessed on June 23, 2020 https://www.accessdata.fda.gov/drugsatfda_docs/label/2020/021168s041lbl.pdf.

Tegretol®-XR FDA label. Accessed on June 23, 2020. https://www.accessdata.fda.gov/drugsatfda_docs/label/2018/016608s115_018281_s058_018927s055_020234_s047.pdf.

Concerta® FDA label. Accessed on June 23, 2020. https://www.accessdata.fda.gov/drugsatfda_docs/label/2017/021121s038lbl.pdf.

Embeda® FDA label. Accessed on June 23, 2020. https://www.accessdata.fda.gov/drugsatfda_docs/label/2019/022321s030lbl.pdf.

Aggrenox® FDA label. Accessed on June 23, 2020. https://www.accessdata.fda.gov/drugsatfda_docs/label/2019/020884s039lbledt.pdf.

Ali SF, Afrooz H, Hampel R, Mohamed EM, Bhattacharya R, Cook P, et al. Blend of cellulose ester and enteric polymers for delayed and enteric coating of core tablets of hydrophilic and hydrophobic drugs. Int J Pharm. 2019;567:118462.

Mwila C, Walker RB. Improved Stability of Rifampicin in the Presence of Gastric-Resistant Isoniazid Microspheres in Acidic Media. Pharmaceutics. 2020;12(3):234.

Eudragit®. Accessed on June 23, 2020. https://healthcare.evonik.com/sites/lists/NC/DocumentsHC/Evonik-Eudragit_brochure.pdf.

Sato H, Uraki Y, Kishimoto T, Sano Y. New process for producing cellulose acetate from wood in concentrated acetic acid. Cellulose. 2003;10(4):397–404.

Puls J, Wilson SA, Hölter D. Degradation of cellulose acetate-based materials: a review. J Polym Environ. 2011;19(1):152–65.

FDA Inactive ingredients database. Accessed on June 24, 2020. https://www.accessdata.fda.gov/scripts/cder/iig/index.cfm?event=BasicSearch.page.

USP43-NF38 – Cellulose acetate, page 5701, 2020.

Ranjan OP, Nayak UY, Reddy MS, Dengale SJ, Musmade PB, Udupa N. Osmotically controlled pulsatile release capsule of montelukast sodium for chronotherapy: statistical optimization, in vitro and in vivo evaluation. Drug Deliv. 2014;21(7):509–18.

Tsiapla AR, Karagkiozaki V, Bakola V, Pappa F, Gkertsiou P, Pavlidou E, et al. Biomimetic and biodegradable cellulose acetate scaffolds loaded with dexamethasone for bone implants. Beilstein J Nanotechnol. 2018;9(1):1986–94.

Guarino V, Caputo T, Calcagnile P, Altobelli R, Demitri C, Ambrosio L. Core/shell cellulose-based microspheres for oral administration of Ketoprofen Lysinate. J Biomed Mater Res B Appl Biomater. 2018;106(7):2636–44.

Liakos IL, Abdellatif MH, Innocenti C, Scarpellini A, Carzino R, Brunetti V, et al. Antimicrobial lemongrass essential oil—copper ferrite cellulose acetate nanocapsules. Molecules. 2016;21(4):520.

Liakos IL, D’autilia F, Garzoni A, Bonferoni C, Scarpellini A, Brunetti V, et al. All natural cellulose acetate—Lemongrass essential oil antimicrobial nanocapsules. Int J Pharm. 2016;510(2):508–15.

Wsoo MA, Shahir S, Bohari SP, Nayan NH, Abd Razak SI. A review on the properties of electrospun cellulose acetate and its application in drug delivery systems: A new perspective. Carbohydr Res. 2020s;5:107978.

Ali SF, Dharani S, Afrooz H, Mohamed EM, Cook P, Khan MA, et al. Development of Abuse-Deterrent Formulations Using Sucrose Acetate Isobutyrate. AAPS PharmSciTech. 2020;21(3):1–4.

Voltaren®-XR FDA label. Accessed on March 03, 2021. https://www.accessdata.fda.gov/drugsatfda_docs/label/2016/020254s028lbl.pdf.

Voltaren® FDA label. Accessed on March 03, 2021. https://www.accessdata.fda.gov/drugsatfda_docs/label/2016/019201s046lbl.pdf.

Rahman Z, Dharani S, Ali SF, Afrooz H, Reddy IK, Khan MA. Effect of processing parameters and controlled environment storage on the disproportionation and dissolution of extended-release capsule of phenytoin sodium. Int J Pharm. 2018;550(1-2):290–9.

ICH harmonized tripartite guideline—Validation of analytical procedures: Text and methodology Q2 (R1), 2005.

Sakai T, Hirai D, Kimura SI, Iwao Y, Itai S. Effects of tablet formulation and subsequent film coating on the supersaturated dissolution behavior of amorphous solid dispersions. Int J Pharm. 2018;540(1-2):171–7.

Porter SC, Ridgway K. The permeability of enteric coatings and the dissolution rates of coated tablets. J Pharm Pharmacol. 1982;34(1):5–8.

Chopra S, Patil GV, Motwani SK. Release modulating hydrophilic matrix systems of losartan potassium: Optimization of formulation using statistical experimental design. Eur J Pharm Biopharm. 2007;66(1):73–82.

Rahman Z, Xu X, Katragadda U, Krishnaiah YS, Yu L, Khan MA. Quality by design approach for understanding the critical quality attributes of cyclosporine ophthalmic emulsion. Mol Pharm. 2014;11(3):787–99.

Wulff R, Leopold CS. Coatings of Eudragit® RL and L-55 blends: investigations on the drug release mechanism. AAPS PharmSciTech. 2016;17(2):493–503.

Hou Y, Wang H, Zhang X, Zou M, Cheng G. Study of the mechanism of cationic drug release increase coated with Surelease® after curing. Asian J Pharm Sci. 2013;8(5):295–302.

EastmanTM Cellulose acetate (CA 398-10 NF/EP)—Technical datasheet. Accessed on July 07, 2020. https://productcatalog.eastman.com/tds/ProdDatasheet.aspx?product=71051329&pn=Cellulose+Acetate+-+CA-398-10NF%2fEP+(National+Formulary+and+European+Pharmacopoeia)#_ga=2.161618940.1511400293.1594055117-1166129648.1591652891.

EastmanTM Cellulose acetate (CA 320S NF/EP)—Technical datasheet. Accessed on July 07, 2020. https://productcatalog.eastman.com/tds/ProdDatasheet.aspx?product=71063628&pn=Cellulose+Acetate+-+CA-320S+NF%2fEP+(National+Formulary+and+European+Pharmacopoeia)#_ga=2.161618940.1511400293.1594055117-1166129648.1591652891.

Sarisuta N, Parrott EL. Relationship of dissolution rate to viscosity of polymeric solutions. J Pharm Sci. 1982;71(12):1375–80.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khuroo, T., Mohamed, E.M., Dharani, S. et al. Coating characterization by hyperspectroscopy and predictive dissolution models of tablets coated with blends of cellulose acetate and cellulose acetate phthalate. AAPS PharmSciTech 22, 122 (2021). https://doi.org/10.1208/s12249-021-01986-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-021-01986-z