Abstract

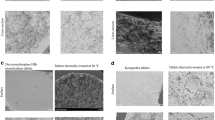

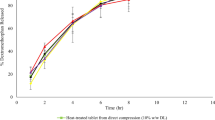

Abuse-deterrent formulations (ADFs) using physical/chemical barrier approaches limit abuse by providing resistance to dosage form manipulation to limit drug extraction or altered release. Standardizing in vitro testing methods to assess the resistance to manipulation presents a number of challenges, including the variation in particle sizes resulting from the use of various tools to alter the tablet matrix (e.g., grinding, chipping, crushing). A prototype, direct-compression ADF using a sintered polyethylene oxide (PEO) matrix containing dextromethorphan, an enantiomeric form of the opioid, levorphanol, was developed to evaluate testing methodologies for retention of abuse-deterrent properties following dosage form tampering. Sintered PEO tablets were manipulated by grinding, and drug content and release were evaluated for the recovered granules. Drug content analysis revealed that higher amounts of drug were contained in the smaller size granules (< 250 μm, 190% of the theoretical amount) compared with the larger particles (> 250 μm, 55–75% of theoretical amount). Release testing was performed on various size granule fractions (> 850 μm, 500–850 μm, 250–500 μm, and < 250 μm) using USP type I (basket), type II (paddle), and type IV (flow-through) apparatus. The USP type I and type II apparatus gave highly variable release results with poor discrimination among the release rates from different size granules. The observed sticking of the hydrated granules to the baskets and paddles, agglomeration of hydrated granules within the baskets/vessels, and ongoing PEO hydration with subsequent gel formation further altered the particle size and impacted the rate of drug release. The use of a flow-through apparatus (USP type IV) resulted in improved discrimination of drug release from different size granules with less variability due to better dispersion of granules (minimal sticking and aggregation). Drug release profiles from the USP type IV apparatus showed that the larger size granules (> 500 μm) offered continued resistance to drug release following tablet manipulation, but the smaller size granules (< 500 μm) provided rapid drug release that was unhindered by the hydrated granule matrix. Since < 500-μm size particles are preferred for nasal abuse, improved direct-compression ADF formulations should minimize the formation of these smaller-sized particles following tampering to maintain the product’s abuse-deterrent features.

Similar content being viewed by others

References

Abd-Elsayed A, Fischer M, Dimbert J, Fiala KJ. Prescription drugs and the US workforce: results from a National Safety Council survey. Pain Phys. 2020;23(1):1–6.

Compton WM, Volkow ND. Abuse of prescription drugs and the risk of addiction. Drug Alcohol Depend. 2006;83:S4–7. https://doi.org/10.1016/j.drugalcdep.2005.10.020.

Becker WC, Fiellin DA. Abuse-deterrent opioid formulations—putting the potential benefits into perspective. N Engl J Med. 2017;376(22):2103–5.

Muppalaneni S, Mastropietro DJ, Omidian H. Crush resistance and insufflation potential of poly(ethylene oxide)-based abuse deterrent formulations. Expert Opin Drug Deliv. 2016;13(10):1375–82. https://doi.org/10.1080/17425247.2016.1211638.

Mastropietro DJ, Omidian H. Abuse-deterrent formulations: part 2: commercial products and proprietary technologies. Expert Opin Pharmacother. 2015;16(3):305–23. https://doi.org/10.1517/14656566.2014.970175.

Mastropietro DJ, Omidian H. Current approaches in tamper-resistant and abuse-deterrent formulations. Drug Dev Ind Pharm. 2013;39(5):611–24. https://doi.org/10.3109/03639045.2012.680468.

Mastropietro DJ, Omidian H. Abuse-deterrent formulations: part 1 – development of a formulation-based classification system. Expert Opin Drug Metab Toxicol. 2015;11(2):193–204. https://doi.org/10.1517/17425255.2015.979786.

Meruva S, Donovan MD. Polyethylene oxide (PEO) molecular weight effects on abuse-deterrent properties of matrix tablets. AAPS PharmSciTech. 2020;21(1):1–10.

Rahman Z, Yang Y, Korang-Yeboah M, Siddiqui A, Xu X, Ashraf M, et al. Assessing impact of formulation and process variables on in-vitro performance of directly compressed abuse deterrent formulations. Int J Pharm. 2016;502(1–2):138–50. https://doi.org/10.1016/j.ijpharm.2016.02.029.

Rahman Z, Zidan AS, Korang-Yeboah M, Yang Y, Siddiqui A, Shakleya D, et al. Effects of excipients and curing process on the abuse deterrent properties of directly compressed tablets. Int J Pharm. 2017;517(1–2):303–11.

Abuse-Deterrent Opioid Analgesics. www.fda.gov [02 March 2020]; Available from: https://www.fda.gov/drugs/postmarket-drug-safety-information-patients-and-providers/abuse-deterrent-opioid-analgesics.

Boyce HJ, Dave VS, Scoggins M, Gurvich VJ, Smith DT, Byrn SR, et al. Physical barrier type abuse-deterrent formulations: mechanistic understanding of sintering-induced microstructural changes in polyethylene oxide placebo tablets. AAPS PharmSciTech. 2020;21(3):86.

Regulatory science report: oral abuse-deterrent opioid products. www.fda.gov; [cited 2019 11 Feb]; Available from: https://www.fda.gov/downloads/ForIndustry/UserFees/GenericDrugUserFees/UCM608676.pdf.

Meruva S, Donovan MD. Effects of drug-polymer interactions on tablet properties during the development of abuse-deterrent dosage forms. AAPS PharmSciTech. 2019;20(3):93. https://doi.org/10.1208/s12249-018-1221-y.

Nukala PK, Palekar S, Patki M, Fu Y, Patel K. Multi-dose oral abuse deterrent formulation of loperamide using hot melt extrusion. Int J Pharm. 2019;569:118629.

Nukala PK, Palekar S, Patki M, Patel K. Abuse deterrent immediate release egg-shaped tablet (egglets) using 3D printing technology: quality by design to optimize drug release and extraction. AAPS PharmSciTech. 2019;20(2):80.

Cone EJ, Giordano J, Weingarten B. An iterative model for in vitro laboratory assessment of tamper deterrent formulations. Drug Alcohol Depend. 2013;131(1–2):100–5.

Xu X, Gupta A, Al-Ghabeish M, Calderon SN, Khan MA. Risk based in vitro performance assessment of extended release abuse deterrent formulations. Int J Pharm. 2016;500(1–2):255–67.

Abuse-deterrent opioids — evaluation and labeling guidance for industry. [cited 2020 02 March]; Available from: https://www.fda.gov/files/drugs/published/Abuse-Deterrent-Opioids-Evaluation-and-Labeling.pdf.

General principles for evaluating the abuse deterrence of generic solid oral opioid drug products - guidance for industry. www.fda.gov [cited 2020 02 March]; Available from: https://www.fda.gov/media/96643/download.

Bartholomaus J, Schwier S, Brett M. New abuse deterrent formulation (ADF) technology for immediate-release opioids. Drug Dev Deliv. 2013;13(8):76–81.

J-i J, Kamada N, Miyake M, Yamada K, Mukai T, Odomi M, et al. Effect of particle size reduction on dissolution and oral absorption of a poorly water-soluble drug, cilostazol, in beagle dogs. J Control Release. 2006;111(1–2):56–64. https://doi.org/10.1016/j.jconrel.2005.11.013.

Waterman KC, Sutton SC. A computational model for particle size influence on drug absorption during controlled-release colonic delivery. J Control Release. 2003;86(2–3):293–304.

Anand O, Lawrence XY, Conner DP, Davit BM. Dissolution testing for generic drugs: an FDA perspective. AAPS J. 2011;13(3):328–35.

Azarmi S, Roa W, Löbenberg R. Current perspectives in dissolution testing of conventional and novel dosage forms. Int J Pharm. 2007;328(1):12–21.

Prabhu NB, Marathe AS, Jain S, Singh PP, Sawant K, Rao L, et al. Comparison of dissolution profiles for sustained release resinates of BCS class I drugs using USP apparatus 2 and 4: a technical note. AAPS PharmSciTech. 2008;9(3):769–73.

Fotaki N, Aivaliotis A, Butler J, Dressman J, Fischbach M, Hempenstall J, et al. A comparative study of different release apparatus in generating in vitro–in vivo correlations for extended release formulations. Eur J Pharm Biopharm. 2009;73(1):115–20.

Bhardwaj U, Burgess DJ. A novel USP apparatus 4 based release testing method for dispersed systems. Int J Pharm. 2010;388(1–2):287–94. https://doi.org/10.1016/j.ijpharm.2010.01.009.

Sievens-Figueroa L, Pandya N, Bhakay A, Keyvan G, Michniak-Kohn B, Bilgili E, et al. Using USP I and USP IV for discriminating dissolution rates of nano- and microparticle-loaded pharmaceutical strip-films. AAPS PharmSciTech. 2012;13(4):1473–82.

Zolnik B, Raton J, Burgess D. Application of USP apparatus 4 and in situ fiber optic analysis to microsphere release testing. Dissolution Technol. 2005;12(2):11–4.

Feng X, Zidan A, Kamal NS, Xu X, Sun D, Walenga R, et al. Assessing drug release from manipulated abuse deterrent formulations. AAPS PharmSciTech. 2020;21(2):1–11.

Dicpinigaitis PV, Morice AH, Birring SS, McGarvey L, Smith JA, Canning BJ, et al. Antitussive drugs—past, present, and future. Pharmacol Rev. 2014;66(2):468–512. https://doi.org/10.1124/pr.111.005116.

Wang J, Flanagan DR. General solution for diffusion-controlled dissolution of spherical particles. 1. Theory. J Pharm Sci. 1999;88(7):731–8.

Wang J, Flanagan DR. General solution for diffusion-controlled dissolution of spherical particles. 2. Evaluation of experimental data. J Pharm Sci. 2002;91(2):534–42.

Langenbucher F. Material and method parameters in dissolution rate studies. Pharm Hecta Alva. 1974;49:187–92.

Siepmann J, Kranz H, Bodmeier R, Peppas N. HPMC-matrices for controlled drug delivery: a new model combining diffusion, swelling, and dissolution mechanisms and predicting the release kinetics. Pharm Res. 1999;16(11):1748–56.

Kim CJ. Drug release from compressed hydrophilic POLYOX-WSR tablets. J Pharm Sci. 1995;84(3):303–6.

Mitra B, Thool P, Meruva S, Aycinena JA, Li J, Patel J, et al. Decoding the small size challenges of mini-tablets for enhanced dose flexibility and micro-dosing. Int J Pharm. 2020;574:118905.

Noyes AA, Whitney WR. The rate of solution of solid substances in their own solutions. J Am Chem Soc. 1897;19(12):930–4.

Boyce H, Smith D, Byrn S, Saluja B, Qu W, Gurvich VJ, et al. In vitro assessment of nasal insufflation of comminuted drug products designed as abuse deterrent using the vertical diffusion cell. AAPS PharmSciTech. 2018;19(4):1744–57.

Sheng JJ, Sirois PJ, Dressman JB, Amidon GL. Particle diffusional layer thickness in a USP dissolution apparatus II: a combined function of particle size and paddle speed. J Pharm Sci. 2008;97(11):4815–29.

Zhang G, Vadino W, Yang T, Cho W, Chaudry I. Evaluation of the flow-through cell dissolution apparatus: effects of flow rate, glass beads and tablet position on drug release from different type of tablets. Drug Dev Ind Pharm. 1994;20(13):2063–78.

Wu Y, Ghaly ES. Effect of hydrodynamic environment on tablet dissolution using flow-through dissolution apparatus. P R Health Sci J. 2006;25(1).

Acknowledgments

The authors would also like to thank Dr. Douglas R. Flanagan for his assistance with the drug dissolution simulations.

Funding

The authors acknowledge the receipt of the Ballard Seashore Dissertation Fellowship from the University of Iowa Graduate College, which provided financial assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meruva, S., Rezaei, L., Thool, P. et al. Use of Drug Release Testing to Evaluate the Retention of Abuse-Deterrent Properties of Polyethylene Oxide Matrix Tablets. AAPS PharmSciTech 21, 270 (2020). https://doi.org/10.1208/s12249-020-01804-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-020-01804-y