Abstract

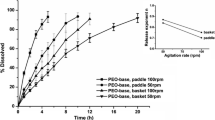

There is a need to develop in vitro dissolution methods that discriminate for particle size of the manipulated abuse deterrent formulation (ADF) and that can be used for in vivo predictive models since dissolution methods developed for intact formulation might not be suitable for manipulated ones. A vertical diffusion cell (VDC) and United States Pharmacopeia (USP) Apparatus 1, 2, and 4 were evaluated for measuring the dissolution of intact and manipulated metoprolol succinate tablets with abuse deterrent-like properties. These tablets were physically manipulated to produce fine (106–500 μm) and coarse (500–1000 μm) powder samples. The VDC method was not able to discriminate the effect of particle size on drug release with varied stirring rate (200 to 800 rpm), molecular weight cut-off (MWCO, 3–5 kDa to 12–14 kDa) of the diffusion membrane, or composition and ionic strength (0.45% and 0.9%) of receiver medium. Standard and modified USP Apparatus 1 and 2 methods were assessed; however, large variations (RSD > 20%) were observed with USP Apparatus 1 for manipulated product dissolution and floating powder samples caused failure of auto-sampling when using standard USP Apparatus 2. For the USP Apparatus 4 dissolution method, packing configuration (1, 3, 8 layers and blend), ionic strength of dissolution medium (0.017, 0.077, and 0.154 M additional NaCl), and flow rate (4, 8, 16 mL/min) were studied to discriminate the effect of particle size on release. The USP Apparatus 4 dissolution method was optimized by using a packaging configuration of 8 layers with 8 mL/min flow rate which exhibited low variability and complete drug release and it could be used for in vivo predictive models. The dissolution method variables can be optimized for a specific product for desirable reproducibility and discriminatory power when using USP Apparatus 4.

Similar content being viewed by others

References

Alexander L, Mannion RO, Weingarten B, Fanelli RJ, Stiles GL. Development and impact of prescription opioid abuse deterrent formulation technologies. Drug Alcohol Depend. 2014;138:1–6.

FDA US. Food and Drug Administration. Guidance for industry: abuse-deterrent opioids — evaluation and labeling. 2015 [Available from: https://www.fda.gov/downloads/Drugs/Guidances/UCM334743.pdf. Accessed 04/05/2019.

Maincent J, Zhang F. Recent advances in abuse-deterrent technologies for the delivery of opioids. Int J Pharm. 2016;510(1):57–72.

Rahman Z, Yang Y, Korang-Yeboah M, Siddiqui A, Xu X, Ashraf M, et al. Assessing impact of formulation and process variables on in-vitro performance of directly compressed abuse deterrent formulations. Int J Pharm. 2016;502(1):138–50.

Xu X, Gupta A, Al-Ghabeish M, Calderon SN, Khan MA. Risk based in vitro performance assessment of extended release abuse deterrent formulations. Int J Pharm. 2016;500(1–2):255–67.

Amidon GL, Lennernäs H, Shah VP, Crison JR. A theoretical basis for a biopharmaceutic drug classification: the correlation of in vitro drug product dissolution and in vivo bioavailability. Pharm Res. 1995;12(3):413–20.

Bhardwaj U, Burgess DJ. A novel USP apparatus 4 based release testing method for dispersed systems. Int J Pharm. 2010;388(1):287–94.

Brown CK, Friedel HD, Barker AR, Buhse LF, Keitel S, Cecil TL, et al. FIP/AAPS joint workshop report: dissolution/in vitro release testing of novel/special dosage forms: Springer; 2011.

Katz N, Dart RC, Bailey E, Trudeau J, Osgood E, Paillard F. Tampering with prescription opioids: nature and extent of the problem, health consequences, and solutions. The American journal of drug and alcohol abuse. 2011;37(4):205–17.

Tur KM, Ch'ng H-S, Baie S. Use of bioadhesive polymer to improve the bioavailability of griseofulvin. Int J Pharm. 1997;148(1):63–71.

Wong S, Kellaway I, Murdan S. Enhancement of the dissolution rate and oral absorption of a poorly water soluble drug by formation of surfactant-containing microparticles. Int J Pharm. 2006;317(1):61–8.

Joshi HN, Tejwani RW, Davidovich M, Sahasrabudhe VP, Jemal M, Bathala MS, et al. Bioavailability enhancement of a poorly water-soluble drug by solid dispersion in polyethylene glycol–polysorbate 80 mixture. Int J Pharm. 2004;269(1):251–8.

Ye X, Patil H, Feng X, Tiwari RV, Lu J, Gryczke A, et al. Conjugation of hot-melt extrusion with high-pressure homogenization: a novel method of continuously preparing Nanocrystal solid dispersions. AAPS PharmSciTech. 2016;17(1):78–88.

Kopecky EA, Fleming AB, Noonan PK, Varanasi RK, Grima M, Saim S, et al. Impact of physical manipulation on in vitro and in vivo release profiles of oxycodone DETERx®: an extended-release, abuse-deterrent formulation. Journal of opioid management. 2014;10(4):233–46.

Boyce H, Smith D, Byrn S, Saluja B, Qu W, Gurvich VJ, et al. In vitro assessment of nasal insufflation of comminuted drug products designed as abuse deterrent using the vertical diffusion cell. AAPS PharmSciTech. 2018:1–14.

Nott KP. Magnetic resonance imaging of tablet dissolution. Eur J Pharm Biopharm. 2010;74(1):78–83.

Hu J, Kyad A, Ku V, Zhou P, Cauchon N. A comparison of dissolution testing on lipid soft gelatin capsules using USP apparatus 2 and apparatus 4. Dissolution Technol. 2005;12(2):6–9.

Browne DC, Kieselmann S. Low-level drug release-rate testing of ocular implants using USP apparatus 4 dissolution and HPLC end analysis. Dissolution Technol. 2010;1:12–4.

Zolnik B, Raton J, Burgess D. Application of USP apparatus 4 and in situ fiber optic analysis to microsphere release testing. Dissolution Technol. 2005;12(2):11–4.

Beyssac E, Lavigne J. Dissolution study of active pharmaceutical ingredients using the flow through apparatus USP 4. Dissolution Technologies. 2005;12(2):23–5.

Rawat A, Stippler E, Shah VP, Burgess DJ. Validation of USP apparatus 4 method for microsphere in vitro release testing using Risperdal® Consta®. Int J Pharm. 2011;420(2):198–205.

Bhattachar SN, Wesley JA, Fioritto A, Martin PJ, Babu SR. Dissolution testing of a poorly soluble compound using the flow-through cell dissolution apparatus. Int J Pharm. 2002;236(1):135–43.

Greiner M, Elts E, Schneider J, Reuter K, Briesen H. Dissolution study of active pharmaceutical ingredients using molecular dynamics simulations with classical force fields. J Cryst Growth. 2014;405:122–30.

May S, Jensen B, Wolkenhauer M, Schneider M, Lehr CM. Dissolution techniques for in vitro testing of dry powders for inhalation. Pharm Res. 2012;29(8):2157–66.

Son Y-J, McConville JT. Development of a standardized dissolution test method for inhaled pharmaceutical formulations. Int J Pharm. 2009;382(1):15–22.

Mastropietro DJ, Omidian H. Abuse-deterrent formulations: part 2: commercial products and proprietary technologies. Expert Opin Pharmacother. 2015;16(3):305–23.

Mastropietro DJ, Omidian H. Current approaches in tamper-resistant and abuse-deterrent formulations. Drug Dev Ind Pharm. 2013;39(5):611–24.

Gupta MK, Goldman D, Bogner RH, Tseng Y-C. Enhanced drug dissolution and bulk properties of solid dispersions granulated with a surface adsorbent. Pharm Dev Technol. 2001;6(4):563–72.

Khan A, Aqil M, Imam SS, Ahad A, Sultana Y, Ali A, et al. Temozolomide loaded nano lipid based chitosan hydrogel for nose to brain delivery: characterization, nasal absorption, histopathology and cell line study. Int J Biol Macromol. 2018;116:1260–7.

Vangani S, Li X, Zhou P, Del-Barrio M-A, Chiu R, Cauchon N, et al. Dissolution of poorly water-soluble drugs in biphasic media using USP 4 and fiber optic system. Clin Res Regul Aff. 2009;26(1–2):8–19.

Shah VP, Tsong Y, Sathe P, Liu J-P. In vitro dissolution profile comparison—statistics and analysis of the similarity factor, f2. Pharm Res. 1998;15(6):889–96.

Wu N, Wang L-S, Tan DC-W, Moochhala SM, Yang Y-Y. Mathematical modeling and in vitro study of controlled drug release via a highly swellable and dissoluble polymer matrix: polyethylene oxide with high molecular weights. J Control Release. 2005;102(3):569–81.

Costa P, Sousa Lobo JM. Modeling and comparison of dissolution profiles. Eur J Pharm Sci. 2001;13(2):123–33.

D'Arcy D, Corrigan O, Healy A. Hydrodynamic simulation (computational fluid dynamics) of asymmetrically positioned tablets in the paddle dissolution apparatus: impact on dissolution rate and variability. J Pharm Pharmacol. 2005;57(10):1243–50.

Crowley MM, Zhang F, Koleng JJ, McGinity JW. Stability of polyethylene oxide in matrix tablets prepared by hot-melt extrusion. Biomaterials. 2002;23(21):4241–8.

Kim CJ. Drug release from compressed hydrophilic POLYOX-WSR tablets. J Pharm Sci. 1995;84(3):303–6.

Ahmed TA, El-Say KM, Ahmed OAA, Zidan AS. Chapter 9 - sterile dosage forms loaded nanosystems for parenteral, nasal, pulmonary and ocular administration. In: Grumezescu AM, editor. Nanoscale Fabrication. Optimization, Scale-Up and Biological Aspects of Pharmaceutical Nanotechnology: William Andrew Publishing; 2018. p. 335–95.

Hong SI, Oh SY. Dissolution kinetics and physical characterization of three-layered tablet with poly (ethylene oxide) core matrix capped by Carbopol. Int J Pharm. 2008;356(1–2):121–9.

Maggi L, Segale L, Torre M, Machiste EO, Conte U. Dissolution behaviour of hydrophilic matrix tablets containing two different polyethylene oxides (PEOs) for the controlled release of a water-soluble drug. Dimensionality study Biomaterials. 2002;23(4):1113–9.

Colombo P, Bettini R, Santi P, Peppas NA. Swellable matrices for controlled drug delivery: gel-layer behaviour, mechanisms and optimal performance. Pharmaceutical Science & Technology Today. 2000;3(6):198–204.

Apicella A, Cappello B, Del Nobile M, La Rotonda M, Mensitieri G, Nicolais L. Poly (ethylene oxide)(PEO) and different molecular weight PEO blends monolithic devices for drug release. Biomaterials. 1993;14(2):83–90.

Hu A, Chen C, Mantle MD, Wolf B, Gladden LF, Rajabi-Siahboomi A, et al. The properties of HPMC:PEO extended release hydrophilic matrices and their response to ionic environments. Pharm Res. 2017;34(5):941–56.

Williams HD, Ward R, Hardy IJ, Melia CD. The extended release properties of HPMC matrices in the presence of dietary sugars. J Control Release. 2009;138(3):251–9.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Disclaimer

This article reflects the views of the author and should not be construed to represent FDA’s views or policies.

Additional information

Guest Editors: Heather Boyce, Steve R. Byrn, and Stephen W. Hoag

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Supplementary Table S1

(DOCX 12 kb)

Rights and permissions

About this article

Cite this article

Feng, X., Zidan, A., Kamal, N.S. et al. Assessing Drug Release from Manipulated Abuse Deterrent Formulations. AAPS PharmSciTech 21, 40 (2020). https://doi.org/10.1208/s12249-019-1595-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-019-1595-5