Abstract

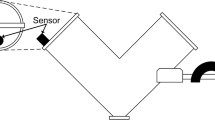

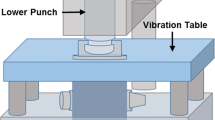

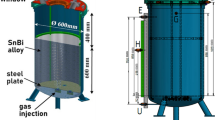

Process analytical technologies are implemented within the pharmaceutical manufacturing process to rectify issues associated with current sampling methods. These include inline monitoring methods such as passive vibration measurements which are non-intrusive and less costly to other methods. In the final mixing stage of the tablet manufacturing process, a lubricant is added to ensure the mixture is ejected from the tablet die cleanly. To monitor this process, an accelerometer was attached to the lid of the V-blender loaded with various particles and magnesium stearate. At a fixed fill level, the lubricant concentration and particle mass were varied to investigate the effects of changes in process parameters on the signal vibrations measured by the sensor, the coefficient of restitution, and the flowability. It was found that measured vibrations from stress waves propagated upon collisions of the particles with the V-shell respond to and can distinguish differences in particles. As well, the magnesium stearate layer around particles alters energy dissipation and subsequently the measured vibrations. A mixing endpoint of uniform distribution of magnesium stearate with primary particles can be identified from vibrations measured by an accelerometer attached to the lid of the V-blender. The flowability change was considered negligible in the particles due to their physical morphology. These findings indicate that passive vibration measurements can be a viable, non-intrusive monitoring method while providing insight into V-blender mixing behaviors as well as improving process efficiency.

Similar content being viewed by others

References

Lemieux M, Bertrand F, Chaouki J, Gosselin P. Comparative study of the mixing of free flowing particles in a V-blender and a bin-blender. Chem Eng Sci. 2007;62:1783–802.

Brone D, Alexander A, Muzzio F. Quantitative characterization of mixing of dry powders in v-blenders. AICHE J. 1998;44:271–8.

Kuo H, Knight P, Parker D, Seville J. Solids circulation and axial dispersion of cohesionless particles in a V-mixer. Powder Technol. 2005;152:133–40.

Lemieux M, Leonard G, Doucet J, Leclaire L, Viens F, Chaouki J, et al. Large-scale numerical investigation of solids mixing in a V-blender using the discrete element method. Powder Technol. 2008;181:205–16.

Perrault M, Bertrand F, Chaouki J. An investigation of magnesium stearate mixing in a V-blender through gamma-ray detection. Powder Technol. 2010;200(3):234–45.

Roblot-Treupel L, Puisieux F. Distribution of magnesium stearate on the surface of lubricated particles. Int J Pharm. 1986;31(1):131–6.

Bossert J, Stains A. Effect of mixing on the lubrication of crystalline lactose by magnesium stearate. Drug Dev Ind Pharm. 1980;6(6):573–89.

Jarosz PJ, Parrott EL. Effect of lubricants on tensile strengths of tablets. Drug Dev Ind Pharm. 1984;10(2):259–73.

Kikuta JI, Kitamori N. Effect of mixing time on the lubricating properties of magnesium stearate and the final characteristics of the compressed tablets. Drug Dev Ind Pharm. 1994;20(3):343–55.

Deveswaran R, Bharath S, Basavaraj BV, Abraham S, Furtado S, Madhavan V. Concepts and techniques of pharmaceutical powder mixing process: a current update. Res J Pharm Technol. 2009;2:245–9.

Garcia T, Wilkinson S, Scott J. The development of a blend-sampling technique to assess the uniformity of a powder mixture. Drug Dev Ind Pharm. 2001;27(4):297–307.

Muzzio FJ, Goodridge CL, Alexander A, Arratia P, Yang H, Sudah O, et al. Sampling and characterization of pharmaceutical powders and granular blends. Int J Pharm. 2003;250:51–64.

Bellamy L, Nordon A, Littlejohn D. Non-invasive monitoring of powder mixing with near infrared spectroscopy and acoustics. Spectrosc Eur. 2004:25–7.

Blanco M, Gozalez B, Bertran E. Monitoring powder blending in pharmaceutical processes by use of near infrared spectroscopy. Talanta. 2002;56:203–12.

Koeller D, Posch A, Hori G, Voura C, Radl S, Urbanetz N, et al. Continuous quantitative monitoring of powder mixing dynamics by near-infrared spectroscopy. Powder Technol. 2011;205:87–96.

De Beer TRM, Bodson C, Dejaegher B, Walczak B, Vercryysse P, Burgraeve A, et al. Raman spectroscopy as a process analytical technology (PAT) tool for the in-line monitoring and understanding of a powder blending process. J Pharm Biomed Anal. 2008;48:772–9.

Breintenbach J, Schrof W, Neumann J. Confocal Raman-spectroscopy: analytical approach to solid dispersions and mapping of drugs. Pharm Res. 1999;16:1109–13.

Vergote G, De Beer T, Vervaet C, Remon J, Baeyens W, Diericx N, et al. In-line monitoring of a pharmaceutical blending process using FT-Raman spectroscopy. Eur J Pharm Sci. 2004;21:479–85.

Nakagawa M, Altobelli SA, Caprihan A, Fukushima E, Jeong EK. Non-invasive measurements of granular flows by magnetic resonance imaging. Exp Fluids. 1993;16:54–60.

Porion P, Sommier N, Faugere AM, Evesque P. Dynamics of size segregation and mixing of granular materials in a 3D-blender by NMR imaging investigation. Powder Technol. 2004;141:55–68.

Sommier N, Porion P, Evesque P, Leclerc B, Tchoreloff P, Couarraze G. Magnetic resonance imaging investigation of the mixing-segregation process in a pharmaceutical blender. Int J Pharm. 2001;222:243–58.

Broadbent CJ, Bridgewater J, Parker DJ. The effect of fill level on powder mixer performance using a positron camera. Chem Eng J. 1995;56:119–25.

Lai FS, Fan LT. A study on the mixing of flour in a motionless Sulzer (Koch) mixer using a radioactive tracer. Powder Technol. 1976;13:73–83.

Aguiar C, Laudares F. Listening to the coefficient of restitution and the gravitational acceleration of a bouncing ball. Am J Phys. 2003;71:499–501.

Müller P, Böttcher R, Russell A, Trüe M, Aman S, Tomas J. Contact time at impact of spheres on large thin plates. Adv Powder Technol; 27.2016, 4, S. 1233–1243.

Jackson RL, Green I, Marghitu DB. Predicting the coefficient of restitution of impacting elastic-perfectly plastic spheres. Nonlinear Dyn. 2010;60:217–29.

Marinack M, Musgrave R, Higgs C. Experimental investigations on the coefficient of restitution of single particles. Tribol Trans. 2013;56(4):572–80.

Tily P, Porada S, Scruby C, Lidington S. Monitoring of mixing processes using acoustic emission. In: Harnby N, Benkreira H, Carpenter K, Mann R, editors. Fluid mixing III. Rugby: The Institute of Chemical Engineers; 1988. p. 75–94.

Allan P, Bellamy L, Nordon A, Littlejohn D. Non-invasive monitoring of the mixing of pharmaceutical powders by broadband acoustic emission. Analyst. 2010;135:518–24.

Crouter A, Briens L. Passive acoustic emissions from particulates in a V-blender. Drug Dev Ind Pharm. 2015;11:1809–18.

Crouter A, Briens L. Monitoring lubricant addition using passive acoustic emissions in a V-blender. Powder Technol. 2016;301:1119–29.

Cameron A, Briens L. An investigation of magnesium stearate mixing performance in a V-blender through passive vibration measurements. AAPS PharmSciTech. 2019;20:199.

Sondergaard R, Chaney K, Brennen C. Measurements of spheres bouncing off flat plates. J Appl Mech, Vol. 1990:112.

Zener C. The intrinsic inelasticity of large plates. Phys Rev. 1941;59:669–73.

Acknowledgment

The authors would like to acknowledge the financial contributions of the Natural Sciences and Research Council (NSERC) of Canada toward this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of Interest Statement

No potential conflict of interest was reported by the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cameron, A., Briens, L. Monitoring Magnesium Stearate Blending in a V-Blender Through Passive Vibration Measurements. AAPS PharmSciTech 20, 269 (2019). https://doi.org/10.1208/s12249-019-1469-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-019-1469-x