Abstract

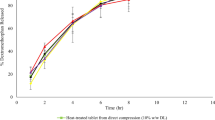

In this study, the effect of formulation variables and process parameters on the abuse-deterrent (AD) characteristics of a matrix tablet manufactured using hot-melt extrusion (HME) was investigated. The formulation variables included polyethylene oxide (PEO) grades and its input level, while the HME process parameters varied were barrel temperature profile and die diameter. Depending on the diameter of the extrudate (2.5 mm or 5.0 mm), two different downstream processes were used to prepare the tablets: cryo-milling followed by compression for the 2.5 mm extrudate, and cutting followed by compression for the 5.0 mm extrudate. A D-optimal statistical design was used to evaluate the impact of formulation and process parameters on various responses, including tablet physical strength, particle size after manipulation, syringeability and injectability, solution viscosity, extractability in solvents, and dissolution rates. It was found that the post-HME extrusion processing method played a critical role in affecting the AD characteristics of abuse-deterrent formulations, likely through changing the tablet compactability and porosity. When the extrudates were cryo-milled-compressed, the tablets could be readily manipulated by milling, which led to high degree of extractability. Under high alcohol concentration, burst drug release was observed for the tablets compressed from cryo-milled extrudates. Additionally, heat exposure during HME process caused significant drop in PEO solution viscosity, likely due to thermal degradation.

Similar content being viewed by others

References

21st Century Cures Act, in H.R. 34 , 114th Congress. 2016.

Katz NP, Adams EH, Chilcoat H, Colucci RD, Comer SD, Goliber P,et al. Challenges in the development of prescription opioid abuse-deterrent formulations. Clin J Pain. 2007;23(8):648–60.

Moorman-Li, R., et al., A review of abuse-deterrent opioids for chronic nonmalignant pain. Pharm Ther, 2012. 37(7): p. 412.

Alexander L, Mannion RO, Weingarten B, Fanelli RJ, Stiles GL. Development and impact of prescription opioid abuse deterrent formulation technologies. Drug Alcohol Depend. 2014;138:1–6.

Cicero TJ, Ellis MS. Abuse-deterrent formulations and the prescription opioid abuse epidemic in the United States: lessons learned from OxyContin. JAMA Psychiat. 2015;72(5):424–30.

Maincent J, Zhang F. Recent advances in abuse-deterrent technologies for the delivery of opioids. Int J Pharm. 2016;510(1):57–72.

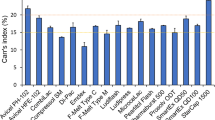

Rahman Z, Zidan AS, Korang-Yeboah M, Yang Y, Siddiqui A, Shakleya D, et al. Effects of excipients and curing process on the abuse deterrent properties of directly compressed tablets. Int J Pharm. 2017;517(1):303–11.

FDA. U.S. General principles for evaluating the abuse deterrence of generic solid oral opioid drug products guidance for industry. 2017.

Xu, X., et al., Risk based in vitro performance assessment of extended release abuse deterrent formulations. Int J Pharm, 2016. 500(1–2): p. 255–267.

Rahman Z, et al. Assessing impact of formulation and process variables on in-vitro performance of directly compressed abuse deterrent formulations. Int J Pharm. 2016;502(1):138–50.

FDA. U.S. Assessment of abuse potential of drugs guidance for industry. 2017.

Peppas, N.A., et al., Poly (ethylene glycol)-containing hydrogels in drug delivery. J Control Release, 1999. 62(1–2): p. 81–87.

Apicella A, et al. Poly (ethylene oxide)(PEO) and different molecular weight PEO blends monolithic devices for drug release. Biomaterials. 1993;14(2):83–90.

Bailey FE. Poly(ethylene oxide). In: Bailey FE Jr, Koleske JV (eds) J.V. Koleske. New York: Academic Press, 1976.

Crowley MM, Zhang F, Koleng JJ, McGinity JW. Stability of polyethylene oxide in matrix tablets prepared by hot-melt extrusion. Biomaterials. 2002;23(21):4241–8.

Zhang F, McGinity JW. Properties of sustained-release tablets prepared by hot-melt extrusion. Pharm Dev Technol. 1999;4(2):241–50.

Gryczke A, Schminke S, Maniruzzaman M, Beck J, Douroumis D. Development and evaluation of orally disintegrating tablets (ODTs) containing Ibuprofen granules prepared by hot melt extrusion. Colloids Surf B: Biointerfaces. 2011;86(2):275–84.

Feng X, Vo A, Patil H, Tiwari RV, Alshetaili AS, Pimparade MB,et al. The effects of polymer carrier, hot melt extrusion process and downstream processing parameters on the moisture sorption properties of amorphous solid dispersions. J Pharm Pharmacol. 2016;68(5):692–704.

Maddineni, S., Battu S.K., Morott J., Soumyajit M., Repka M.A., Formulation optimization of hot-melt extruded abuse deterrent pellet dosage form utilizing design of experiments. J Pharm Pharmacol, 2014. 66(2): p. 309–322.

Bartholomaeus JH, Arkenau-Marić E, Galia E. Opioid extended-release tablets with improved tamper-resistant properties. Exp Opin Drug Deliv. 2012;9(8):879–91.

Casettari L, Bonacucina G, Cespi M, Perinelli DR, Micheli M, Cacciatore I, et al. Effect of manufacturing temperature and molecular weights on compression, mechanical and dissolution properties of PEO matrix tablets. J Drug Deliv Sci Technol. 2016;32:236–40.

Yang X, Zhong Z, Huang Y. The effect of PEG molecular weights on the thermal stability and dissolution behaviors of griseofulvin-PEG crystalline inclusion complexes. Int J Pharm. 2016;508(1):51–60.

Yang L, Heatley F, Blease TG, Thompson RIG. A study of the mechanism of the oxidative thermal degradation of poly (ethylene oxide) and poly (propylene oxide) using 1H-and 13C-NMR. Eur Polym J. 1996;32(5):535–47.

de Sainte Claire P. Degradation of PEO in the solid state: a theoretical kinetic model. Macromolecules. 2009;42(10):3469–82.

Voorhees KJ, Baugh SF, Stevenson DN. An investigation of the thermal degradation of poly (ethylene glycol). J Anal Appl Pyrolysis. 1994;30(1):47–57.

Scheirs J, Bigger SW, Delatycki O. Characterizing the solid-state thermal oxidation of poly (ethylene oxide) powder. Polymer. 1991;32(11):2014–9.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editors: Heather Boyce, Steve R. Byrn, and Stephen W. Hoag

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 742 kb)

Rights and permissions

About this article

Cite this article

Xu, X., Siddiqui, A., Srinivasan, C. et al. Evaluation of Abuse-Deterrent Characteristics of Tablets Prepared via Hot-Melt Extrusion. AAPS PharmSciTech 20, 230 (2019). https://doi.org/10.1208/s12249-019-1448-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-019-1448-2