Abstract

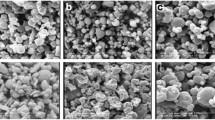

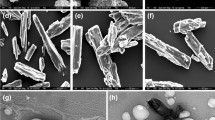

Proliposome formulations containing salbutamol sulphate (SS) were developed using spray drying, and the effects of carrier type (lactose monohydrate (LMH) or mannitol) and lipid to carrier ratio were evaluated. The lipid phase comprised soy phosphatidylcholine (SPC) and cholesterol (1:1), and the ratios of lipid to carrier were 1:2, 1:4, 1:6, 1:8 or 1:10 w/w. X-ray powder diffraction (XRPD) revealed an interaction between the components of the proliposome particles, and scanning electron microscopy (SEM) showed that mannitol-based proliposomes were uniformly sized and spherical, whilst LMH-based proliposomes were irregular and relatively large. Using a two-stage impinger (TSI), fine particle fraction (FPF) values of the proliposomes were higher for mannitol-based formulations, reaching 52.6%, which was attributed to the better flow properties when mannitol was used as carrier. Following hydration of proliposomes, transmission electron microscopy (TEM) demonstrated that vesicles generated from mannitol-based formulations were oligolamellar, whilst LMH-based proliposomes generated ‘worm-like’ structures and vesicle clusters. Vesicle size decreased upon increasing carrier to lipid ratio, and the zeta potential values were negative. Drug entrapment efficiency (EE) was higher for liposomes generated from LMH-based proliposomes, reaching 37.76% when 1:2 lipid to carrier ratio was used. The in vitro drug release profile was similar for both carriers when 1:6 lipid to carrier ratio was used. This study showed that spray drying can produce inhalable proliposome microparticles that can generate liposomes upon contact with an aqueous phase, and the FPF of proliposomes and the EE offered by liposomes were formulation-dependent.

Similar content being viewed by others

References

Taylor KM, Taylor G, Kellaway IW, Stevens J. The influence of liposomal encapsulation on sodium cromoglycate pharmacokinetics in man. Pharm Res. 1989;6:633–6.

Zeng XM, Martin GP, Marriott C. The controlled delivery of drugs to the lung. Int J Pharm. 1995;124:149–64.

Ehsan Z, Wetzel JD, Clancy JP. Nebulized liposomal amikacin for the treatment of Pseudomonas aeruginosa infection in cystic fibrosis patients. Expert Opin Investig Drugs. 2014;23:743–9.

Lee W-H, Loo C-Y, Traini D, Young PM. Inhalation of nanoparticle-based drug for lung cancer treatment: advantages and challenges. Asian J Pharm Sci. 2015;10:481–9.

Elhissi A. Liposomes for pulmonary drug delivery: the role of formulation and inhalation device design. Curr Pharm Des. 2017;23:362–72.

Saari M, Vidgren MT, Koskinen MO, Turjanmaa VMH, Nieminen MM. Pulmonary distribution and clearance of two beclomethasone formulations in healthy volunteers. Int J Pharm. 1999;181:1–9.

Clancy JP, Dupont L, Konstan MW, Billings J, Fustik S, Goss CH, et al. Phase II studies of nebulised Arikace in CF patients with Pseudomonas aeruginosa infection. Thorax. 2013;68:818–25.

Rudokas M, Najlah M, Alhnan MA, Elhissi A. Liposome delivery systems for inhalation: a critical review highlighting formulation issues and anticancer applications. Med Princ Pract. 2016;25(Suppl 2):60–72.

Cipolla D, Blanchard J, Gonda I. Development of liposomal ciprofloxacin to treat lung infections. Pharmaceutics. 2016;8 https://doi.org/10.3390/pharmaceutics8010006.

Elhissi AM, Faizi M, Naji WF, Gill HS, Taylor KM. Physical stability and aerosol properties of liposomes delivered using an air-jet nebulizer and a novel micropump device with large mesh apertures. Int J Pharm. 2007;2334:62–70.

Ghazanfari T, Elhissi AM, Ding Z, Taylor KM. The influence of fluid physicochemical properties on vibrating-mesh nebulization. Int J Pharm. 2007;339:103–11.

Najlah M, Vali A, Taylor M, Arafat BT, Ahmed W, Phoenix DA, et al. A study of the effects of sodium halides on the performance of air-jet and vibrating-mesh nebulizers. Int J Pharm. 2013;456:520–7.

Elhissi AMA, Karnam KK, Danesh-Azari M-R, Gill HS, Taylor KMG. Formulations generated from ethanol-based proliposomes for delivery via medical nebulizers. J Pharm Pharmacol 2006. 2006;58:887–94.

Schreier H, McNicol KJ, Ausborn M, Soucy DM, Derendorf H, Stecenko AA, et al. Pulmonary delivery of amikacin liposomes and acute liposome toxicity in the sheep. Int J Pharm. 1992;87:183–93.

Mobley WC. The effect of jet-milling on lyophilized liposomes. Pharm Res. 1998;15:149–52.

Lu D, Hickey AJ. Liposomal dry powders for pulmonary delivery of proteins. AAPS PharmSciTech. 2005;6:E641–8.

Radhakrishnan, R., Mihalko, P.J., Abra, R.M. Method and apparatus for administering dehydrated liposomes by inhalation. US patent No 4895719, 1990.

Lo YL, Tsai JC, Kuo JH. Liposomes and disaccharides as carriers in spray-dried powder formulations of superoxide dismutase. J Cont Rel. 2004;94:259–72.

Chougule MB, Padhi BK, Misra A. Nano-liposomal dry powder inhaler amiloride hydrochloride. J Nanosci Nanotechnol. 2006;6:3001–9.

Chougule M, Padhi B, Misra A. Development of spray dried liposomal dry powder inhaler of Dapsone. AAPS PharmSciTech. 2008;9:47–53.

Ourique AF, Chaves Pdos S, Souto GD, Pohlmann AR, Guterres SS, Beck RC. Redispersible liposomal-N-acetylcysteine powder for pulmonary administration: development, in vitro characterization and antioxidant activity. Eur J Pharm Sci. 2014;65:174–82.

Payne NI, Timmins P, Ambrose CV, Ward MD, Ridgway F. Proliposomes: a novel solution to an old problem. J Pharm Sci. 1986;75:325–9.

Payne NI, Browning I, Hynes CA. Characterization of proliposomes. J Pharm Sci. 1986;75:330–3.

Desai TR, Wong JP, Hancock RE, Finlay WH. A novel approach to the pulmonary delivery of liposomes in dry powder form to eliminate the deleterious effects of milling. J Pharm Sci. 2002;91:482–91.

Desai TR, Hancock REW, Finlay WH. Delivery of liposomes in dry powder form: aerodynamic dispersion properties. Eur J Pharm Sci. 2003;20:459–67.

Alves GP, Santana MHA. Phospholipid dry powders produced by spray drying processing: structural, thermodynamic and physical properties. Powder Technol. 2004;145:139–48.

Rojanarat W, Changsan N, Tawithong E, Pinsuwan S, Chan H-K, Srichana T. Isoniazid proliposome powders for inhalation—preparation, characterization and cell culture studies. Int J Mol Sci. 2011;12:4414–34.

Rojanarat W, Nakpheng T, Thawithong E, Yanyium N, Srichana T. Inhaled pyrazinamide proliposome for targeting alveolar macrophages. Drug Delivery. 2012;19:334–45.

Lawaczeck R, Kainosho M, Chan SI. The formation and annealing of structural defects in lipid bilayer vesicles. Biochim Biophys Acta. 1976;443:313–30.

Cevher E, Orhan Z, Mülazimoğlu L, Sensoy D, Alper M, Yildiz A, et al. Characterization of biodegradable chitosan microspheres containing vancomycin and treatment of experimental osteomyelitis caused by methicillin-resistant Staphylococcus aureus with prepared microspheres. Int J Pharm. 2006;317:127–35.

Hallworth GW, Westmoreland DG. The twin impinger: a simple device for assessing the delivery of drugs from metered dose pressurized aerosol inhalers. J Pharm Pharmacol. 1987;39:966–72.

Maury M, Murphy K, Kumar S, Shi L, Lee G. Effects of process variables on the powder yield of spray-dried trehalose on a laboratory spray-dryer. Eur J Pharm Biopharm. 2005;59:565–73.

Maa YF, Nguyen PA, Sit K, Hsu CC. Spray-drying performance of a bench-top spray dryer for protein aerosol powder preparation. Biotechnol Bioeng. 1998;60:301–9.

Bhandari BR, Datta N, Howes T. Problems associated with spray drying of sugar-rich foods. Dry Technol. 1997;15:671–84.

Bhandari B, Howes T. Implication of glass transition for the drying and stability of dried foods. J Food Eng. 1999;40:71–9.

Abbas KA, Lasekan O, Khalil SK. The significance of glass transition temperature in processing of selected fried food products: a review. Modern Appl Sci. 2010;4:3–21.

Truong V. Glass transition temperature and spray drying of sugar-rich foods: modelling and stickiness. LAP LAMBERT Academic Publishing, Saarbrücken, 2014.

Roos Y. Melting and glass transitions of low molecular weight carbohydrates. Carbohydr Res. 1993;238:39–48.

Roos Y, Karel M. Plasticizing effect of water on thermal behavior and crystallization of amorphous food models. J Food Sci. 1991;56:38–43.

Imtiaz-Ul-Islam M, Langrish TAG. Comparing the crystallization of sucrose and lactose in spray dryers. Food Bioprod Process. 2009;87:87–95.

Yu, L., Mishra, D.S., Rigsbee, D.R., 1998. Determination of the glass properties of D-mannitol using sorbitol as an impurity. J Pharm Sci, 87:774–777.

Telang C, Suryanarayanan R, Yu L. Crystallization of D-mannitol in binary mixtures with NaCl: phase diagram and polymorphism. Pharm Res. 2003;20:1939–45.

Yoshinari T, Forbes RT, York P, Kawashima Y. Crystallisation of amorphous mannitol is retarded using boric acid. Int J Pharm. 2003;258:109–20.

Shiga H, Joreau H, Neoh TL, Furuta T, Yoshii H. Encapsulation of alcohol dehydrogenase in mannitol by spray drying. Pharmaceutics. 2014;6:185–94.

Chan H-K. Dry powder aerosol delivery systems: current and future research directions. J Aerosol Med. 2006;19:21–7.

Byron PR. Prediction of drug residence times in regions of the human respiratory tract following aerosol inhalation. J Pharm Sci. 1986;75:433–8.

Dozan T, Benkovic´ M, Bauman I. Sucrose particle size reduction—determination of critical particle diameters causing flowability difficulties. J Hyg Eng Des. 2014;8:3–10.

Wang, J., Shi, Q., Huang, Z., Gu, Y., Musango, L., Yang, Y., 2015. Experimental investigation of particle size effect on agglomeration behaviors in gas–solid fluidized beds. Ind Eng Chem Res, 54:12177–12186.

Pilcer G, Wauthoz N, Amighi K. Lactose characteristics and the generation of the aerosol. Adv Drug Del Rev. 2012;64:233–56.

Kou X, Chan LW, Steckel H, Heng PWS. Physico-chemical aspects of lactose for inhalation. Adv Drug Del Rev. 2012;64:220–32.

Daniher DI, Zhu J. Dry powder platform for pulmonary drug delivery. Particuology. 2008;6:225–38.

Scichilone N, Spatafora M, Battaglia S, Arrigo R, Benfante A, Bellia V. Lung penetration and patient adherence considerations in the management of asthma: role of extra-fine formulations. J Asthma Allergy. 2013;6:11–21.

de Boer AH, Gjaltema D, Hagedoorn P, Frijlink HW. Can “extrafine” dry powder aerosols improve lung deposition? Eur J Pharm Biopharm. 2015;96:143–51.

Merchant Z, Buckton G, Taylor KM, Stapleton P, Saleem IY, Zariwala MG, et al. Pulmonary delivery of nano-antimicrobial therapeutics to treat chronic pulmonary infections. Curr Pharm Des. 2016;22:2577–98.

Harjunen P, Lehto V-P, Martimo K, Suihko E, Lankinen T, Paronen P, et al. Lactose modifications enhance its drug performance in the novel multiple dose Taifun DPI. Eur J Pharm Sci. 2002;16:313–21.

Larhrib H, Martin GP, Marriott C, Prime D. The influence of carrier and drug morphology on drug delivery from dry powder formulations. Int J Pharm. 2003;257:283–96.

Zhang Q, Yang H, Yan W. Effect of ethanol on the crystallinity and acid sites of MFI zeolite nanosheets. RSC Adv. 2014;4:56938–44.

Ebrahimi A, Saffari M, Langrish T. Developing a new production process for high-porosity lactose particles with high degrees of crystallinity. Powder Technol. 2015;272:45–53.

Sebhatu T, Angberg M, Ahlneck C. Assessment of the degree of disorder in crystalline solids by isothermal microcalorimetry. Int J Pharm. 1994;104:135–44.

Hancock BC, Zografi G. Characteristics and significance of the amorphous state in pharmaceutical systems. J Pharm Sci. 1997;86:1–12.

Bennett RC, Brough C, Miller DA, O’Donnell KP, Keen JM, Hughey JR, et al. Preparation of amorphous solid dispersions by rotary evaporation and KinetiSol dispersing: approaches to enhance solubility of a poorly water-soluble gum extract. Drug Dev Ind Pharm. 2015;41:382–97.

Shin GH, Li J, Cho JH, Kim JT, Park HJ. Enhancement of curcumin solubility by phase change from crystalline to amorphous in Cur-TPGS nanosuspension. J Food Sci. 2016;81:N494–501.

White GW, Cakebread SH. The glassy state in certain sugar-containing food products. Int J Food Sci Tech Res. 1966;1:73–82.

Pia Fäldt BB. The surface composition of spray-dried protein-lactose powders. Colloids Surf Physicochem Eng Asp. 1994;90:183–90.

Darcy P, Buckton G. The influence of heating/drying on the crystallisation of amorphous lactose after structural collapse. Int J Pharm. 1997;158:157–64.

Wu L, Miao X, Shan Z, Huang Y, Li L, Pan X, et al. Studies on the spray dried lactose as carrier for dry powder inhalation. Asian J Pharm Sci. 2014;9:336–41.

Amdadul Haque M, Chen J, Aldred P, Adhikari B. Denaturation and physical characteristics of spray dried whey protein isolate powders produced in the presence and absence of lactose, trehalose and polysorbate-80. Dry Technol. 2015;33:1243–54.

Kawashima Y, Serigano T, Hino T, Yamamoto H, Takeuchi H. Effect of surface morphology of carrier lactose on dry powder inhalation property of pranlukast hydrate. Int J Pharm. 1998;172:179–88.

Pilcer G, Amighi K. Formulation strategy and use of excipients in pulmonary drug delivery. Int J Pharm. 2010;392:1–19.

Hupfeld S, Holsaeter AM, Skar M, Frantzen CB, Brandl M. Liposome size analysis by dynamic/static light scattering upon size exclusion-/field flow-fractionation. J Nanosci Nanotechnol. 2006;6:3025–31.

Abra RM, Mihalko PJ, Schreier H. The effect of lipid composition upon the encapsulation and in vitro leakage of metaproterenol sulfate from 0.2μm diameter, extruded, multilamellar liposomes. J Cont Rel. 1990;14:71–8.

Betageri GV, Parsons DL. Drug encapsulation and release from multilamellar and unilamellar liposomes. Int J Pharm. 1992;81:235–41.

Laouini A, Jaafar-Maalej C, Limayem-Blouza I, Sfar S, Charcosset C, Fessi H. Preparation, characterization and applications of liposomes: state of the art. J Colloid Sci Biotechnol. 2012;1:147–68.

Debbage P. Targeted drugs and nanomedicine: present and future. Curr Pharm Des. 2009;15:153–72.

Gabizon A, Price DC, Huberty J, Bresalier RS, Papahadjopoulos D. Effect of liposome composition and other factors on the targeting of liposomes to experimental tumors: biodistribution and imaging studies. Cancer Res. 1990;50:6371–8.

Straubinger RM, Hong K, Friend DS, Papahadjopoulos D. Endocytosis of liposomes and intracellular fate of encapsulated molecules: encounter with a low pH compartment after internalization in coated vesicles. Cell. 1983;32:1069–79.

Elhissi AMA, Ahmed W, McCarthy D, Taylor KMG. A study of size, microscopic morphology, and dispersion mechanism of structures generated on hydration of proliposomes. J Disp Sci Tech. 2012;33:1121–6.

Gupta PK, Hickey AJ. Contemporary approaches in aerosolized drug delivery to the lung. J Cont Rel. 1991;17:127–47.

Carr R. Evaluating flow properties of solids. Chem Eng. 1965;72:163–8.

Elkordy AA, Forbes RT, Barry BW. Integrity of crystalline lysozyme exceeds that of a spray-dried form. Int J Pharm. 2002;247:79–90.

Al-Nimry SS, Alkhamis KA. Effect of moisture content of chitin-calcium silicate on rate of degradation of cefotaxime sodium. AAPS PharmSciTech. 2018;19:1337–43.

Saleem IY, Diez F, Jones BE, Kayali N, Polo L. Investigation on the aerosol performance of dry powder inhalation hypromellose capsules with different lubricant levels. Int J Pharm. 2015;492:258–63.

de Boer AH, Chan HK, Price R. A critical view on lactose-based drug formulation and device studies for dry powder inhalation: which are relevant and what interactions to expect? Adv Drug Del Rev. 2012;64:257–74.

Yoshida H, Kuwana A, Shibata H, Izutsu KI, Goda Y. Comparison of aerodynamic particle size distribution between a next generation impactor and a cascade impactor at a range of flow rates. AAPS PharmSciTech. 2017;18:646–53.

Abadelah M, Chrystyn H, Bagherisadeghi G, Abdalla G, Larhrib H. Study of the emitted dose after two separate inhalations at different inhalation flow rates and volumes and an assessment of aerodynamic characteristics of indacaterol Onbrez Breezhaler® 150 and 300 μg. AAPS PharmSciTech. 2018;19:251–61.

Acknowledgements

We thank MIAT, Italy for supplying us with the Monodose dry powder inhaler device. We also thank Mr. David McCarthy, Microscopy unit, UCL-School of Pharmacy for the TEM images and Lipoid, Switzerland for supplying us with SPC (Lipoid S-100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Electronic Supplementary Material

ESM 1

(PDF 196 kb)

Rights and permissions

About this article

Cite this article

Omer, H.K., Hussein, N.R., Ferraz, A. et al. Spray-Dried Proliposome Microparticles for High-Performance Aerosol Delivery Using a Monodose Powder Inhaler. AAPS PharmSciTech 19, 2434–2448 (2018). https://doi.org/10.1208/s12249-018-1058-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-018-1058-4