Abstract

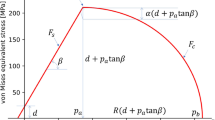

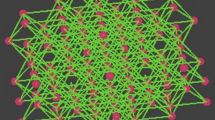

The closed-die compaction behaviour of D-mannitol granules has been simulated by the discrete element method (DEM) to investigate the granule rearrangement and fracture behaviour during compaction which affects the compactibility of the tablet. The D-mannitol granules produced in a fluidized bed were modelled as agglomerates of primary particles connected by linear spring bonds. The validity of the model granule used in the DEM simulation was demonstrated by comparing to the experimental results of a uniaxial compression test. During uniaxial compression, the numerical results of the force-displacement curve corresponded reasonably well to the experimental data. The closed-die compaction of the modelled granules was carried out to investigate the rearrangement and fracture behaviours of the granule at different upper platen velocities. The forces during closed-die compaction calculated by DEM fluctuated in the low-pressure region due to the rearrangement of granules. A Heckel analysis showed that the force fluctuation occurred at the initial bending region of the Heckel plot, which represents the granule rearrangement and fracture. Furthermore, the upper platen velocity affected the trend of compaction forces, which can lead to compaction failure due to capping. These results could contribute to designing the appropriate granules during closed-die compaction.

Similar content being viewed by others

REFERENCES

Beekman WJ, Meesters GMH, Becker T, Gaertner A, Gebert M, Scarlett B. Failure mechanism determination for industrial granules using a repeated compression test. Powder Technol. 2003;130(1-3):367–76.

Antonyuk S, Tomas J, Heinrich S, Morl L. Breakage behavior of spherical granulates by compression. Chem Eng Sci. 2005;60(14):4031–44.

Antonyuk S, Heinrich S, Tomas J, Deen NG, Buijtenen MS, Kuipers JAM. Energy absorption during compression and impact of dry elastic-plastic spherical granules. Granul Matter. 2010;12(1):15–47.

Eckhard S, Nebelung M. Investigations of the correlation between granule structure and deformation behavior. Powder Technol. 2011;206(1-2):79–87.

Sheng Y, Briscoe BJ, Maung R, Rovea C. Compression of polymer bound alumina agglomerates at athe micro deformation scale. Powder Technol. 2004;140(3):228–39.

Muller P, Seeger M, Tomas J. Compression and breakage behavior of γ-Al2O3 granules. Powder Technol. 2013;237:125–33.

Russell A, Muller P, Shi H, Tomas J. Influences of loading rate and preloading on the mechanical properties of dry elasto-plastic granules under compression. AIChE J. 2014;60(12):4037–50.

Subero J, Ning Z, Ghadiri M, Thornton C. Effect of interface energy on the impact strength of agglomerates. Powder Technol. 1999;105(1-3):66–73.

Thornton C, Ciomocos MT, Adams MJ. Numerical simulation of agglomerate impact breakage. Powder Technol. 1999;105(1-3):74–82.

Kafui KD, Thornton C. Numerical simulation of impact breakage of a spherical crystalline agglomerate. Powder Technol. 2000;109(1-3):113–32.

Moreno R, Ghadiri M, Antony SJ. Effect of the impact angle on the breakage of agglomerates: a numerical study using DEM. Powder Technol. 2003;130(1-3):132–7.

Golchert, D., Moreno, R., Ghadiri, M., Litster, J., Effect of granule morphology on breakage behaviour during compression, Powder Technol. 2004;143-144:84-96.

Thornton C, Ciomocos MT, Adams MJ. Numerical simulations of diametrical compression tests on agglomerates. Powder Technol. 2004;140(3):258–67.

Antonyuk S, Khanal M, Tomas J, Heinrich S, Morl L. Impact breakage of spherical granules: experimental study and DEM simulation. Chem Eng Process. 2006;45(10):838–56.

Antonyuk S, Palis S, Heinrich S. Breakage behaviour of agglomerates and crystals by static loading and impact. Powder Technol. 2011;206(1-2):88–98.

Metzger MJ, Glasser BJ. Numerical investigation of the breakage of bonded agglomerates during impact. Powder Technol. 2012;217:304–14.

Schilde C, Burmeister CF, Kwade A. Measurement and simulation of micromechanical properties of nanostructured aggregates via nanoindentation and DEM-simulation. Powder Technol. 2014;259:1–13.

Henley KJ, O’Sullivan C, Oliveira JC, Cronin K, Byrne EP. Application of Taguchi methods to DEM calibration of bonded agglomerates. Powder Technol. 2011;210(3):230–40.

Henley KJ, O’Sullivan C, Byrne EP, Cronin K. Discrete element modelling of the quasi-static uniaxial compression of individual infant formula agglomerates. Particuology. 2012;10(5):523–31.

Heckel RW. Density-pressure relationships in powder compaction. Trans Metall Soc AIME. 1961;221:671–5.

Heckel RW. An analysis of powder compaction phenomena. Trans Metall Soc AIME. 1961;221:1001–8.

Celik M. Overview of compaction data analysis techniques. Drug Dev Ind Pharm. 1992;18(6-7):767–810.

Hassanpour A, Ghadiri M. Distinct element analysis and experimental evaluation of the Heckel analysis of bulk powder compression. Powder Technol. 2004;141(3):251–61.

Samimi A, Hassanpour A, Ghadiri M. Single and bulk compressions of soft granules: experimental study and DEM evaluation. Chem Eng Sci. 2005;60(14):3993–4004.

Persson AS, Frenning G. An experimental evaluation of the accuracy to simulate granule bed compression using the discrete element method. Powder Technol. 2012;219:249–56.

Siiria SM, Antikainen O, Heinamaki J, Yliruusi J. 3D simulation of internal tablet strength during tableting. AAPS PharmSciTech. 2011;12(2):593–602.

Mehrotra A, Chaudhuri B, Faqih A, Tomassone MS, Muzzio FJ. A modeling approach for understanding effects of powder flow properties on tablet weight variability. Powder Technol. 2009;188(3):295–300.

Martin CL, Bouvard D. Discrete element simulations of the conpaction of aggregated ceramic powders. J Am Ceram Soc. 2006;89(11):3379–87.

Balakrishnan A, Pizette P, Martin CL, Joshi SV, Saha BP. Effect of particle size in aggregated and agglomerated ceramic powders. Acta Mater. 2010;58(3):802–12.

Garr JSM, Rubinstein MH. An investigation into the capping of paracetamol at increasing speeds of compression. Int J Pharm. 1991;72(2):117–22.

Furukawa R, Chen Y, Horiguchi A, Takagaki K, Nishi J, Konishi A, et al. Numerical evaluation of the capping tendency of microcrystalline cellulose tablets during a diametrical compression test. Int J Pharm. 2015;493(1-2):182–91.

Bika D, Tardos GI, Panmai S, Farber L, Michaels J. Strength and morphology of solid bridges in dry granules of pharmaceutical powders. Powder Technol. 2005;150(2):104–16.

Cundall PA, Strack ODL. A discrete numerical model for granular assemblies. Geotechnique. 1979;29(1):47–65.

Mindlin RD. Compliance of elastic bodies in contact. J Appl Mech. 1949;16:259–66.

Ennis BJ, Tardos G, Pfeffer R. A microlevel-based characterization of granulation phenomena. Powder Technol. 1991;65(1-3):257–72.

Liu LX, Lister JD, Iveson SM, Ennis BJ. Coalescence of deformable granules in wet granulation processes. AIChE J. 2000;46(3):529–39.

Iveson SM, Litster JD, Hapgood K, Ennis BJ. Nucleation, growth and breakage phenomena in agitated wet granulation processes; a review. Powder Technol. 2001;117(1-2):3–39.

Rumpf H. Grundlagen und methoden des granulieren. Chem Ing Tech. 1958;30:144–58.

Gröger T, Tüzünm U, Heyes DM. Modelling and measuring of cohesion in wet granular materials. Powder Technol. 2003;133(1-3):203–15.

Yang RY, Yu AB, Choi SK, Coates MS, Chan HK. Agglomeration of fine particles subjected to centripetal compaction. Powder Technol. 2008;184(1):122–9.

Hoblitzell JR, Rhodes CT. Determination of a relationship between force-displacement and force-time compression curves. Drug Dev Ind Pharm. 1990;16(2):201–29.

Tye CK, Sun C, Amidon GE. Evaluation of the effects of tableting speed on the relationships between compaction pressure, tablet tensile strength, and tablet solid fraction. J Pharm Sci. 2005;94(3):465–72.

Klevan I, Nordstrom J, Bauer-Brandl A, Alderborn G. On the physical interpretation of the initial bending of a Shapiro-Konopicky-Heckel compression profile. Eur J Pharm Biopharm. 2009;71(2):395–401.

Klevan I, Nordstrom J, Tho I, Alderborn G. A statistical approach to evaluate the potential use of compression parameters for classification of pharmaceutical powder materials. Eur J Pharm Biopharm. 2010;75(3):425–35.

Nordström J, Klevan I, Alderborn G. A particle rearrangement index based on the kawakita powder compression equation. J Pharm Sci. 2009;98(3):1053–63.

Kawakita K, Ludde K-H. Some considerations on powder compression equations. Powder Technol. 1971;4(2):61–8.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Furukawa, R., Kadota, K., Noguchi, T. et al. DEM Modelling of Granule Rearrangement and Fracture Behaviours During a Closed-Die Compaction. AAPS PharmSciTech 18, 2368–2377 (2017). https://doi.org/10.1208/s12249-017-0719-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-017-0719-z