Abstract

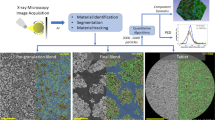

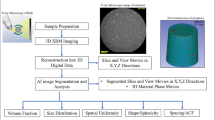

Early risk detection and quick diagnosis of manufacturing challenges are necessary to support the accelerated development pace of drug product in the current competitive environment. Analytical tools, such as near-infrared (NIR) chemical imaging (CI), can be employed for alerting drug substance uniformity risks in intermediates and the final product of solid dosage forms. In this particular study, the ability to characterize the behavior of agglomerated drug substance throughout process development was enabled by NIR CI to identify uniformity risks with small sample sizes and short turnaround time. Using NIR chemical imaging, the drug substance distribution and cluster size in all intermediates were visualized throughout the drug product process. NIR CI enabled rapid identification of the key unit operations that produced the greatest reduction in cluster size for enhanced distribution of the drug substance. The comil acted as a high shear mixing step to disperse soft lumps prior to roller compaction. Shear forces or pressure during roller compaction was sufficient to break down and disperse the agglomerates further. Ultimately, the process was robust against a range of drug substance input properties such that the uniformity of the final blend was consistently achieved and the agglomerated drug substance had no risks to the drug product process.

Similar content being viewed by others

References

Yu LX. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2007;25(4):781–91.

Gupta A, Peck GE, Miller RW, Morris KR. Real-time near-infrared monitoring of content uniformity, moisture content, compact density, tensile strength, and Young’s modulus of roller compacted powder blends. J Pharm Sci. 2005;94(7):1589–97.

Bakeev KA. Process analytical technology: spectroscopic tools and implementation strategies for the chemical and pharmaceutical industries. Blackwell Publishing Ltd.; 2005.

Read EK, Park JT, Shah RB, Riley BS, Brorson KA, Rathore AS. Process analytical technology (PAT) for biopharmaceutical products: part I. Concepts and applications. Biotechnol Bioeng. 2009;105(2):276–84.

Blanco M, Alcalá M. Content uniformity and tablet hardness testing of intact pharmaceutical tablets by near infrared spectroscopy: a contribution to process analytical technologies. Anal Chim Acta. 2006;557:353–9.

Lyon RC, Lester DS, Lewis EN, Lee E, Yu LX, Jefferson EH, et al. Near-infrared spectral imaging for quality assurance of pharmaceutical products: analysis of tablets to assess powder blend homogeneity. AAPS PharmSciTech. 2002;3(3).

Amigo JM, Cruz J, Bautista M, Maspoch S, Coello J, Blanco M. Study of pharmaceutical samples by NIR chemical-image and multivariate analysis. Trends Anal Chem. 2008;27(8):696–713.

Moes JJ, Ruijken MM, Gout E, Frijlink HW, Ugwoke MI. Application of process analytical technology in tablet process development using NIR spectroscopy: blend uniformity, content uniformity and coating thickness measurements. Int J Pharm. 2008;357:108–18.

Lewis EN, Schoppelrei J, Lee E. Near-infrared chemical imaging and the PAT initiative. Spectroscopy. 2004;26–36.

<905> Uniformity of dosage units. Stage 6 harmonization. The United States Pharmacopeial Convention, 2011.

Hausman DS, Cambron RT, Sakr A. Application of Raman spectroscopy for on-line monitoring of low dose blend uniformity. Int J Pharm. 2005;298:80–90.

Gendrin C, Roggo Y, Collet C. Pharmaceutical applications of vibrational chemical imaging and chemometrics: a review. J Pharm Biomed Anal. 2008;48:533–53.

de Juan A, Tauler R, Dyoson R, Marcolli C, Rault M, Maeder M. Spectroscopic imaging and chemometrics: a powerful combination for global and local sample analysis. Trends Anal Chem. 2004;23(1):70–9.

Rhodes M. Mixing and segregation. Introduction to particle technology. 2nd ed. England: Wiley; 2008. p. 293–304.

Muzzio FJ, Goodridge CL, Alexander A, Arratia P, Yang H, Sudah O, et al. Sampling and characterization of pharmaceutical powders and granular blends. Int J Pharm. 2003;250:51–64.

Muzzio FJ, Robinson P, Wightman C, Brone D. Sampling practices in powder blending. Int J Pharm. 1996;155:153–78.

El-Hagrasy AS, Morris HR, D’Amico F, Lodder RA, Drennen JK. Near-infrared spectroscopy and imaging for the monitoring of powder blend homogeneity. J Pharm Sci. 2001;90(9):1298–307.

Westenberger BJ, Ellison CD, Fussner AS, Jenney S, Kolinski RE, Lipe TG, et al. Quality assessment of internet pharmaceutical products using traditional and non-traditional analytical techniques. Int J Pharm. 2005;306:56–70.

Manley M. Near-infrared spectroscopy and hyperspectral imaging: non-destructive analysis of biological materials. Chem Soc Rev. 2014.

Li W, Woldu A, Kelly R, McCool J, Bruce R, Rasmussen H, et al. Measurement of drug agglomerates in powder blending simulation samples by near infrared chemical imaging. Int J Pharm. 2007;350:369–73.

Clarke F. Extracting process-related information from pharmaceutical dosage forms using near infrared microscopy. Vib Spectrosc. 2004;34:25–35.

Šašiċ S, Kong A, Kaul G. Determining API domain sizes in pharmaceutical tablets and blends upon varying milling conditions by near-infrared chemical imaging. Anal Methods. 2013;5:2360–8.

Cruz J, Blanco M. Content uniformity studies in tablets by NIR-CI. J Pharm Biomed Anal. 2011;56:408–12.

Amigo JM, Ravn C. Direct quantification and distribution assessment of major and minor components in pharmaceutical tablets by NIR-chemical imaging. Eur J Pharm Sci. 2009;37:76–82.

Roggo Y, Edmond A, Chalus P, Ulmschneider M. Infrared hyperspectral imaging for qualitative analysis of pharmaceutical solid forms. Anal Chim Acta. 2005;535:79–87.

Roggo Y, Jent N, Edmond A, Chalus P, Ulmschneider M. Characterizing process effects on pharmaceutical solid forms using near-infrared spectroscopy and infrared imaging. Eur J Pharm Biopharm. 2005;61:100–10.

Yekpe K, Abatzoglou N, Bataille B, Gosselin R, Sharkawi T, Simard J-S, et al. Predicting the dissolution behavior of pharmaceutical tablets with NIR chemical imaging. Int J Pharm. 2015;486:242–51.

Ravn C, Skibsted E, Bro R. Near-infrared chemical imaging (NIR-CI) on pharmaceutical solid dosage forms—comparing common calibration approaches. J Pharm Biomed Anal. 2008;48:554–61.

Shekunov BY, York P. Crystallization processes in pharmaceutical technology and drug delivery design. J Cryst Growth. 2000;211:122–36.

Šašiċ S, Yu W, Zhang L. Monitoring of API particle size during solid dosage form manufacturing process by chemical imaging and particle sizing. Anal Methods. 2010;3:568–74.

Rohrs BR, Amidon GE, Meury RH, Secreast PJ, King HM, Skoug CJ. Particle size limits to meet USP content uniformity criteria for tablets and capsules. J Pharm Sci. 2006;95(5):1049–59.

Zhang Y, Johnson KC. Effect of drug particle size on content uniformity of low-dose solid dosage forms. Int J Pharm. 1997;154:179–83.

Kim S, Lotz B, Lindrud M, Girard K, Moore T, Nagarajan K, et al. Control of the particle properties of a drug substance by crystallization engineering and the effect on drug product formulation. Org Process Res Dev. 2005;9:894–901.

Stieger N, Liebenberg W. Recrystallization of active pharmaceutical ingredients. In: Andreeta MRB, editor. Crystallization—science and technology. Intech; 2012. pp. 183–204.

Terrazas-Velarde K, Peglow M, Tsotsas E. Stochastic simulation of agglomerate formation in fluidized bed spray drying: a micro-scale approach. Chem Eng Sci. 2009;64:2631–43.

Llusa M, Sturm K, Sudah O, Stamato H, Goldfarb DJ, Ramachandruni H, et al. Effect of high shear blending protocols and blender parameters on the degree of API agglomeration in solid formulations. Ind Eng Chem Res. 2009;48:93–101.

Sacré P, De Bleye C, Chavez PF, Netchacovitch L, Hubert P, Ziemons E. Data processing of vibrational chemical imaging for pharmaceutical applications. J Pharm Biomed Anal. 2014;101:123–40.

Lasch P. Spectral pre-processing for biomedical vibrational spectroscopy and microspectroscopic imaging. Chemom Intell Lab Syst. 2012;117:100–14.

Kucheryavski S. Using hard and soft models for classification of medical images. Chemom Intell Lab Syst. 2007;88:100–7.

Amigo JM, Ravn C, Gallagher N, Bro R. A comparison of a common approach to partial least squares-discriminant analysis and classical least squares in hyperspectral imaging. Int J Pharm. 2009;373:179–82.

Möltgen C, Puchert T, Menezes J, Lochmann D, Reich G. A novel in-line NIR spectroscopy application for the monitoring of tablet film coating in an industrial scale process. Talanta. 2012;92:26–37.

Muzzio F, Alexander A. Scale up of powder-blending operations. Pharma Technol. 2005;s34–s44.

Acknowledgments

The authors would like to acknowledge Omar Sprockel and Weixian Shi for the valuable discussions regarding drug product development and Sharif Shasad, Yan Zhang, Judy Lin, and Duohai Pan for the analytical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Scherholz, M.L., Wan, B. & McGeorge, G. A Rational Analysis of Uniformity Risk for Agglomerated Drug Substance Using NIR Chemical Imaging. AAPS PharmSciTech 18, 432–440 (2017). https://doi.org/10.1208/s12249-016-0523-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-016-0523-1