Abstract

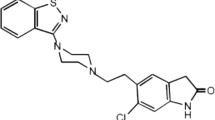

The purpose of this study was to develop a physicomechanically customizable oral metal chelatory in situ hot melt dispersion mini-pellet entity which could be utilized within a binary drug delivery system. Avicel® RC/CL type R-591 was included within the in situ hot melt dispersion mini-pellet formulations to determine the physicomechanical effect this compound would have on the mini-pellet formulations. The physicomechanical properties of the hot melt in situ mini-pellet formulations were mathematically fitting to regression curves. Physicomechanical adjustment of the in situ hot melt dispersion mini-pellet formulations could be mathematically predicted with the derived regression curve equations. The addition of Avicel® RC/CL type R-591 increased the physicomechanical properties such as matrix hardness and increased total disintegration of the in situ hot melt dispersion mini-pellet formulations. The utilization of a physicomechanically customizable oral metal chelatory in situ hot melt dispersion mini-pellet entity within a binary drug delivery system would to achieve a synergistically enhance the activity of a drug-carrying entity or a permeation enhancing entity within a single drug delivery unit. The experimental results indicated that weights of the pellets that achieved optimal hardness ranged between 35 and 45 mg. The melt–dispersion formulations disintegrated within shorter time periods and maintained higher ethylenediaminetetraacetic acid (EDTA) concentrations whereas melt–dispersion formulations which included Avicel® had superior physicomechanical properties. Disintegration times ranged between 1,000 s for melt–dispersions containing EDTA and methyloxy polyethylene glycol 2000 (mPEG) only, to >6,000 s for melt–dispersions comprising EDTA, mPEG, and Avicel®.

Similar content being viewed by others

References

Makhlof A, Werle M, Tozuka Y, Takeuchi H. A mucoadhesive nanoparticulate system for the simulataneous delivery of macromolecules and permeation enhancers to the intestinal mucosa. J Control Release. 2011;149(1):81–8.

Dünnhaupt S, Barthelmes J, Iqbal J, Perera G, Thurner CC, Friedl H, et al. In vivo evaluation of an oral drug delivery system for peptides based on S-protected thiolated chitosan. J Control Release. 2012;160(3):477–85.

Pillay V, Hibbins AR, Choonara YE, du Toit LC, Kumar P, Ndesendo VMK. Orally administered therapeutic peptide delivery: enhanced absorption through the small intestine using permeation enhancers. Int J Pept Res Ther. 2012;18(3):259–80.

Amidi M, Mastrobattista E, Jiskoot W, Hennink WE. Chitsan-based delivery systems for protein therapeutics and antigens. Adv Drug Deliv Rev. 2010;62(1):59–82.

Breitenbach J. Melt extrusion: from process to drug delivery technology. Euro J Pharm Biopharm. 2002;54(2):107–17.

Bernkop-Schnürch A, Paikl C, Valenta C. Novel bioadhesive chitosan-EDTA conjugate protects leucine enkephalin from degradation by aminopeptidase N. Pharmaceut Res. 1997;14(7):917–22.

Peppas NA, Kavimandan NJ. Nanoscale analysis of protein and peptide absorption: insulin absorption using complexation and pH-sensitive hydrogels as delivery vehicles. Eur J Pharm Sci. 2006;29(3–4):183–97.

Bravo-Osuna I, Millotti G, Vauthier C, Ponchel G. In vitro evaluation of calcium binding apacity of chitosan and thiolated chitosan poly(isobutyl cyanoacrylate) core–shell nanoparticles. Int J Pharm. 2007;338(1–2):284–90.

Whitehead K, Mitragotri S. Mechanistic analysis of chemical permeation enhancers for oral delivery. Pharm Res. 2008;25(6):1412–9.

Westberg C, Benkestock K, Fatouros A, Svensson M, Sjӧstrӧm B. Hexarelin evaluation of factors influencing oral bioavailability and ways to improve absorption. J Pharm Pharmacol. 2001;53(9):1257–64.

Graziano JH. Conceptual and practical advances in the measurement and clinical management of lead toxicity. NeuroToxicology. 1993;14(2–3):219–24.

Rudraraju VS, Wyandt CM. Rheological characterization of microcrystalline cellulose/sodiumcarboxymethyl cellulose hydrogels using a controlled stress rheometer: part I. Int J Pharm. 2005;292(1–2):53–61.

Zhao GH, Kapur N, Carlin B, Selinger E, Guthrie JT. Characterisation of the interactive properties of microcrystalline cellulose-carboxymethyl cellulose hydrogels. Int J Pharm. 2011;415(1–2):95–101.

Prodduturi S, Manek RV, Kolling WM, Stodghil SP, Repka MA. Solid-state stability and characterization of hot-melt extruded poly(ethylene oxide) films. J Pharm Sci. 2005;94(10):2232–45.

Murphy DJ, Sankalia MG, Loughlin RG, Donnelly RF, Jenkins MG, Carron PAM. Physical characterization and component release of poly(vinyl alchol)-tetrahydroxyborate hydrogels and their applicability as potential topical drug delivery systems. Int J Pharm. 2012;423(2):326–34.

El-Arini SK, Clas S-D. Evaluation of disintegration testing of different fast dissolving tablets using the texture analyzer. Pharm Dev Technol. 2002;7(3):361–71.

Khoshmanesh A, Cook PLM, Wood BR. Quantitative determination of polyphosphate in sediments using attenuated total reflectance-Fourier transform infrared (ATR-FTIR) spectroscopy and partial least square regression. Analyst. 2012;137:3704–9.

de Sousa FB, Oliveira MF, Lula IS, Sansiviero MTC, Cotés ME, Sinisterra RD. Study of inclusion compound in solution involving tetracycline and β-cyclodextrin by FTIR-ATR. Vib Spectrosc. 2008;46(1):57–62.

Lloyd GR, Craig DQM, Smith A. An investigation into the melting behaviour of binary mixes and solid dispersions of paracetamonl and PEG 4000. J Pharm Sci. 1997;86(9):991–6.

Qi S, Gryczke A, Belton P, Craig DQM. Characterisation of solid dispersions of paracetamol and Eudragit®E prepared by hot-melt extrusion using thermal microthermal and spectroscopic analysis. Int J Pharm. 2008;354(1–2):158–67.

Andrews GP, Abudiak OA, Jones DS. Physicochemical characterization of hot melt extruded bicalutamide-polyvinylpyrrolidone solid dispersion. J Pharm Sci. 2010;99(3):1322–35.

Gu L, Strickley RG, Chi L-H, Chowhan ZT. Drug-excipient incompatibility studies of dipeptide angiotension-converting enzyme inhibitor, moexipril hydrochloride: drug powder vs wet granulation. Pharm Res. 1990;7(4):379–83.

Sanganwar GP, Salthigari S, Babu RJ, Gupta RB. Simultaneous production and co-mixing of microparticles of nevirapine and excipients by supercritical antisolvent method for dissolution enhancement. Euro J Pharm Sci. 2010;31(1–3):164–74.

Sarode AL, Sandhu H, Shah N, Malick W, Zia H. Hot melt extrusion (HME) for amorphous solid dispersions: predictive tools for processing and impact of drug–polymer interactions on supersaturation. Euro J Pharm Sci. 2013;48(3):371–84.

Ellison CD, Ennis BJ, Hamad ML, Lyon RC. Measuring the distribution of density and tabletting force in pharmaceutical tablets by chemical imaging. J Pharm Biomed Anal. 2008;48(1):1–7.

van der Voort Maarschalk K, Zuurman K, Vromans H, Bolhuis GK, Lerk CF. Porosity expansion of tablets as a result of bonding and deformation of particulate solids. Int J Pharm. 1996;140(2):185–93.

Bashaiwoldu AB, Podczeck F, Newton JM. Compaction of and drug release from coated pellets of different mechanical properties. Adv Powder Technol. 2011;22(3):340–53.

Craig DQM. The mechanisms of drug release from solid dispersions in water-soluble polymers. Int J Pharm. 2002;231(2):131–44.

Singhal D, Curatolo W. Drug polymorphism and dosage form design: a practical perspective. Adv Drug Deli Rev. 2004;56(3):335–47.

Acknowledgments

The work is funded by the National Research Fund (NRF) of South Africa.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

ESM 1

DOCX 92 kb

Rights and permissions

About this article

Cite this article

Hibbins, A.R., Choonara, Y.E., Kumar, P. et al. Physicomechanical Characterization and Optimization of EDTA–mPEG and Avicel®–EDTA–mPEG In Situ Melt Dispersion Mini-Pellets. AAPS PharmSciTech 14, 935–949 (2013). https://doi.org/10.1208/s12249-013-9979-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-013-9979-4