Abstract

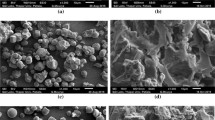

Tigernut starch has been isolated and modified by forced retrogradation of the acidic gel by freezing and thawing processes. Relevant physicochemical and functional properties of the new excipient (tigernut starch modified by acid gelation and accelerated (forced) retrogradation (STAM)) were evaluated as a direct compression excipient in relation to the native tigernut starch (STNA), intermediate product (tigernut starch modified by acid gelation (STA)), and microcrystalline cellulose (MCC). The particle morphology, swelling capacity, moisture sorption, differential scanning calorimeter (DSC) thermographs and X-ray powder diffraction (XRD) patterns, flow, dilution capacity, and tablet disintegration efficiency were evaluated. The particles of STNA were either round or oval in shape, STA were smooth with thick round edges and hollowed center while STAM were long, smooth, and irregularly shaped typically resembling MCC. The DSC thermographs of STNA and MCC showed two endothermic transitions as compared with STA and STAM which showed an endothermic and an exothermic. The moisture uptake, swelling, flow, and dilution capacity of STAM were higher than those of MCC, STA, and STNA. The XRD pattern and moisture sorption profile of STAM showed similarities and differences with STNA, STA, and MCC that relate the modification. Acetylsalicylic acid (ASA) tablets containing STAM disintegrated at 3 ± 0.5 min as compared with the tablets containing STNA, STA, and MCC which disintegrated at 8.5 ± 0.5, 10 ± 0.5, and 58 ± 0.8 min, respectively. The study shows the physicochemical properties of tigernut starch modified by forced retrogradation as well as its potential as an efficient direct compression excipient with enhanced flow and disintegration abilities for tablets production.

Similar content being viewed by others

Abbreviations

- STNA :

-

Native tigernut starch

- STA :

-

Tigernut starch modified by acid gelation

- STAM :

-

Tigernut starch modified by acid gelation and accelerated (forced) retrogradation

- MCC:

-

Microcrystalline cellulose

- Apn:

-

Acetaminophen

- ASA:

-

Acetyls alicylic acid

- SEM:

-

Scanning electron micrograph

- RH:

-

Relative humidity

REFERENCES

Attama AA, Builders PF. Particulate drug delivery: recent applications of natural biopolymers. In: Adikwu MU, editor. Biopolymer in drug delivery: recent advances and challenges. Bentham e-Books; 2009. p. 63–94. http://www.benthamdirect.org/pages/b_getarticlebybook.php.

Moorthy SN. Physicochemical and functional properties of tropical tuber starches: a review. Starch-Starke. 2002;54:559–92.

Korhonen O, Raatikainen P, Harjunen P, Nakari J, Suihko E, Peltonen S, et al. Starch acetates-multifunctional direct compression excipients. Pharm Res. 2000;17:1138–43.

Ojinnaka MC, Akobundu ENT, Iwe MO. Cocoyam starch modification effects on functional, sensory and cookies qualities. Pak J Nutr. 2009;8(5):558–67.

Kim YK, Robyt JF. Enzyme modification of starch granules: formation and retention of cyclomaltodextrins inside starch granules by reaction of cyclomaltodextrin glucanosyltransferase with solid granules. Carbohydr Res. 2000;328(4):509–15.

Jane J, Seib PA. Preparation of granular cold water swelling/soluble starches by alcoholic-alkali treatments. Patent 5057157 Issued on October 15, 1991. Estimated Expiration Date: October 22, 2010. Freepatentsonline http://www.freepatentsonline.com/5057157.html.

Oyi AR, Apeji YE, Musa H. Compact analysis of microcrystalline cassava starch—a direct compression binder. Niger J Pharm Sci. 2009;8(2):59–65.

Bolhuis GK, Chowhan ZT. Materials for direct compression, pharmaceutical powder compaction technology. In: Alderborn G, Nystrom C, editors. Pharmaceutical powder compaction technology. USA: Marcel Dekker; 1996. p. 419–99.

Bodga MJ. Tablet compression: machine theory, design and process troubleshooting. In: Swarbrick J, Boylan J. editors. Encyclopedia of Pharmaceutical Technology. New York: Marcel Dekker Inc.; 2002. p. 719–99.

Toro-Vazquez JF, Gómez-Aldapa CA. Chemical and physicochemical properties of maize starch after industrial nixtamalization. Cereal Chem. 2001;78(5):543–50.

Henry G, Westby A. Global cassava end-uses and markets: current situation and recommendations for further study. Final Report of a Fao Consultancy. Montpellier: CIRAD-AMIS; 1998.

Alexander RJ. Potato starch: new prospects for an old product. Cereal Food World. 1995;40(10):763–4.

Woolfe JA. Sweet potato: an untapped food resource. Cambridge: Cambridge University Press; 1992.

Manek RV, Kunle OO, Emeje MO, Builders PF, Rama Rao GV, Lopez GP, et al. Physical, Thermal and sorption profile of starch obtained from Tacca leontopetaloides. Starch-Starke. 2005;57:55–61.

Manek RV, Builders PF, Kolling WM, Emeje M, Kunle OO. Physicochemical and binder properties of starch obtained from Cyperus esculentus. AAPS PharmSciTech. 2012;13(2):1–10. doi:10.1208/s12249-012-9761-z.

Belewu MA, Abodunrin OA. Preparation of kunnu from unexploited rich food source: tigernut (Cyperus esculentus). Pak J Nutr. 2008;7(1):109–11.

Lowe J, Stanfield DP. The flora of Nigeria sedge (Family Cypraceae). Ibadan: Ibadan University Press; 1974.

Adejuyitan JA, Otunola ET, Akande EA, Bolarinwa IF, Oladokun FM. Some physicochemical properties of flour obtained from fermentation of tigernut (Cyperus esculentus) sourced from a market in Ogbomoso, Nigeria. Afr J Food Sci. 2009;3(2):051–5.

Abano EE, Amoah KK. Effect of moisture content on the physical properties of tigernut (Cyperus esculentus). Asian J Agric Res. 2001;5(1):56–66.

Cantalejo MJ. Analysis of volatile components derived from raw and roasted earth almond (Cyperus esculentus L.). J Agric Food Chem. 1997;45:1853–60.

Sathe SK, Salunkhe DK. Isolation, partial characterization and modification of the great Northern bean (Phaseolus vulgaris L.) starch. J Food Sci. 1981;46:617–21.

Builders PF, Chukwu C, Obidike I, Builders M, Attama AA, Adikwu MU. A novel xyloglucan gum from seeds of Afzelia africana Se. Pers.: some functional and physicochemical properties. Inter J Green Pharm, 2009; 3:112–8.

Builders PF, Nnurum A, Mbah CC, Attama AA, Manek R. The physicochemical and binding properties of starch from Persea americana Miller (Lauraceae). Starch-Starke. 2010;62:309–20.

Well J. Pharmaceutical preformulation the physicochemical properties of drug substances. In: Aulton ME, editor. The science of dosage form design. Toronto: Churchill Livingstone; 2003. p. 113–35.

Builders PF, Isimi YC, Kunle OO. Gum from the bark of Anogeissius leiocarpus, as a potential pharmaceutical raw material-granule properties. J Pharm Bio-resour. 2005;2(1):85–91.

Quinn JR, Paton DA. Practical measurement of water hydration capacity of protein materials. Cereal Chem. 1979;56:38–40.

Kornblum SS, Stoopak SB. A new tablet disintegrant agent: crosslinked polyvinylpyrollidone. J Pharm Sci. 1973;62(1):43–9.

Beristain C, Perez-Alonso CI, Lobato-Calleros C, Rodriguez-Huezo ME, Vernon-Carter EJ. Thermodynamic analysis of the sorption isotherms of pure and blended carbohydrate polymers. J Food Eng. 2006;77:753–60.

Lin YC, Chen X. Moisture sorption–desorption–resorption characteristics and its effect on the mechanical behaviour of the epoxy system. Polymer. 2005;46:11994–2003.

Builders PF, Agbo MB, Adelakun T, Okpako LC, Attama AA. Novel multifunctional pharmaceutical excipients derived from microcrystalline cellulose-starch microparticulate composites prepared by compatibilized reactive polymer blending. Int J Pharm. 2010;388:159–67.

Bi YX, Sunada H, Danjo K. Evaluation of rapidly disintegrating tablets prepared by a direct compression method. Drug Dev Ind Pharm. 1999;25:571–81.

Pharmacopoeia B. The British Pharmacopoeia Commission, vol. II. UK: HMSO; 1993.

Emelugo BN, Umerie SC, Okonkwo IF, Achufusi JN. Evaluation of the tubers and oil of Cyperus rotundus Linn (Cyperaceae). Pak J Nutr. 2011;10(2):147–50.

Linssen JPH, Cozijnsen JL, Pilnik W. Chufa (Cyperus esculentus): a new source of dietary fiber. J Food Sci Agric. 1989;49(3):291–96.

Chung YL, Lai HM. Molecular and granular characteristics of corn starch modified by HCl-methanol at different temperatures. Carbohydr Polym. 2006;63:527–34.

Lin JH, Lee SY, Chang YH. Effect of acid-alcohol treatment on the molecular structure and physicochemical properties of maize and potato starches. Carbohydr Polym. 2003;53:475–82.

Danjo K, Kinoshita K, Kitagawa K, Iida K, Sunada H, Otsuka A. Effect of particle shape on the compaction and flow properties of powders. Chem Pharm Bull. 1989;37(11):3070–3.

Ansel HC, Allen LV, Popovich NG. Ansel’s pharmaceutical dosage forms and drug delivery systems. 8th ed. Philadelphia: Linppincott Williams and Wilkins; 2005.

Zografi G, Kontny MJ. The interactions of water with cellulose- and starch-derived pharmaceutical excipients. Pharm Res. 1986;3:187–94.

Sair L, Fetzer WR. Water sorption by starches. Ind J Eng Chem. 1944;36:205–08.

Burnett DJ, Thielmann F, Sokoloski T, Brum J. Investigating the moisture-induced crystallization kinetics of spray-dried lactose. Int J Pharm. 2006;313:23–8.

Tester RF, Morrison WR. Swelling and gelatinzation of cereal starches: waxy rice starches. Cereal Chem. 1990;67:558–63.

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, et al. Reporting physicsorption data for gas/solid systems with special reference to the determination of surface area and porosity (recommendations). J Pure Appl Chem. 1985;57:603–19.

Rouquerol F, Rouquerol J, Sing K. Adsorption by powders and porous solids. London: Academic; 1999.

Bell L, Labuza TP. Moisture sorption: practical aspects of isotherm measurement and use. 2nd ed. St. Paul: American Association of Cereal Chemists; 2000.

Calandrelli L, Immirzi B, Malinconico M, Volpe MG, Oliva A, Della RF. Preparation and characterization of composites based on biodegradable polymers for “in vivo” application. Polymer. 2000;41:8027–33.

Mark HF, Bikales N, editors. Encyclopedia of polymer science and engineering; “crystallinity determination.” Encyclopedia of polymer science and engineering. New York: Wiley; 1989. p. 482–87.

Zobel HF. Molecules to granules: a comprehensive starch review. Starch-Starke. 1998;40:44–50.

Atichokudomchaia N, Shobsngob S, Chinachotic P, Varavinita S. A study of some physicochemical properties of high-crystalline tapioca starch. Starch-Starke. 2001;53:577–81.

Rickard JE, Asaoka M, Blanshard JMV. The physicochemical properties of cassava starch. Trop Sci. 1991;31:189–207.

Takeda Y, Tokunaga N, Takeda C, Hizukuri S. Physicochemical properties of sweet potato starches. Starch-Starke. 1986;38:345–50.

Defloor I, Dehing I, Delcour JA. Physicochemical properties of cassava starch. Starch-Starke. 1998;50:58–64.

Zhao N, Augsburger LL. Functional comparison of three classes of superdisintegrants in promoting aspirin tablets disintegration and dissolution. AAPS PharmSciTech. 2005;6:634–40.

Caramella C, Colombo P, Conte U, et al. Water uptake and disintegrating force measurements: towards a general understanding of disintegration mechanisms. Drug Dev Ind Pharm. 1986;12:1749–66.

Alderborn G, Nyström C. Radial and axial tensile strength and strength variability of paracetamol tablets. ACTA Pharm Suec. 1984;21:1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Builders, P.F., Anwunobi, P.A., Mbah, C.C. et al. New Direct Compression Excipient from Tigernut Starch: Physicochemical and Functional Properties. AAPS PharmSciTech 14, 818–827 (2013). https://doi.org/10.1208/s12249-013-9968-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-013-9968-7