Abstract

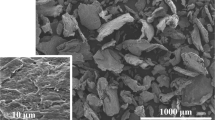

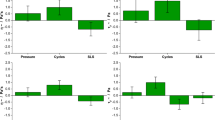

The purpose of this study was to evaluate the potential of cellulose nanofibers (also referred as microfibrillated cellulose, nanocellulose, nanofibrillated, or nanofibrillar cellulose) as novel tabletting material. For this purpose, physical and mechanical properties of spray-dried cellulose nanofibers (CNF) were examined, and results were compared to those of two commercial grades of microcrystalline cellulose (MCC), Avicel PH101 and Avicel PH102, which are the most commonly and widely used direct compression excipients. Chemically, MCC and CNF are almost identical, but their physical characteristics, like mechanical properties and surface-to-volume ratio, differ remarkably. The novel material was characterized with respect to bulk and tapped as well as true density, moisture content, and flow properties. Tablets made of CNF powder and its mixtures with MCC with or without paracetamol as model compound were produced by direct compression and after wet granulation. The tensile strength of the tablets made in a series of applied pressures was determined, and yield pressure values were calculated from the measurements. With CNF, both wet granulation and direct compression were successful. During tablet compression, CNF particles were less prone to permanent deformation and had less pronounced ductile characteristics. Disintegration and dissolution studies showed slightly faster drug release from direct compression tablets with CNF, while wet granulated systems did not have any significant difference.

Similar content being viewed by others

References

Hult EL, Larsson PT, Iversen T. Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer. 2001;42:3309–14.

Turbak AF, Snyder FW, Sandberg KR. Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci. 1983;37:815–27.

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR. Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci. 1983;37:797–813.

Chakraborty A, Sain M, Kortschot M. Cellulose microfibrils: a novel method of preparation using high shear refining and cryocrushing. Holzforschung. 2005;59:102–7.

Quiévy N, Jacquet N, Sclavons M, Deroanne C, Paquot M, Devaux J. Influence of homogenization and drying on the thermal stability of microfibrillated cellulose. Polym Degrad Stabil. 2010;95:306–14.

Svagan AJ, Azizi Samir MAS, Berglund LA. Biomimetic polysaccharide nanocomposites of high cellulose content and high toughness. Biomacromolecules. 2007;8:2556–63.

Pääköö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, et al. Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules. 2007;8:1934–41.

Siro I, Plackett D. Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose. 2010;17:459–94.

Yano H, Sugiyama J, Nakagaito A, Nogi M, Matsuura T, Hikita M, et al. Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater. 2005;17:153–5.

Zimmermann T, Pohler E, Geiger T. Cellulose fibrils for polymer reinforcement. Adv Eng Mater. 2004;6:754–61.

Dufresne A, Cavaille JY, Vignon MR. Mechanical behavior of sheets prepared from sugar beet cellulose microfibrils. J Appl Polym Sci. 1997;64:1185–94.

Nakagaito AN, Yano H. Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A. 2005;80:155–9.

Lu J, Wang T, Drzal LT. Preparation and properties of microfibrillated cellulose polyvinyl alcohol composite materials. Compos Part A. 2008;39:738–46.

Nakagaito AN, Fujimura A, Sakai T, Hama Y, Yano H. Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Compos Sci Technol. 2009;69:1293–7.

Gabr MH, Elrahman MA, Okubo K, Fujii T. Effect of microfibrillated cellulose on mechanical properties of plain-woven CFRP reinforced epoxy. Compos Struct. 2010;92:1999–2006.

European Pharmacopeia. 7th ed. Strasbourg: Council of Europe; 2010

Carr RL. Classifying flow of solids. Chem Eng. 1967;72:69–72.

Hausner HH. Friction conditions in a mass of metal powder. Int J Powder Metall. 1967;3:7–13.

Fell JT, Newton JM. Determination of tablet strength by the diametral compression test. J Pharm Sci. 1970;59:668–91.

USP 27/NF 22 (United States Pharmacopeia 27/National Formulary 22), Washington, DC; 2003

Wells JI. Pharmaceutical preformulation: the physicochemical properties of drug substances. New York: Wiley; 1988.

Doelker E. Comparative compaction properties of various microcrystalline cellulose types and generic products. Drug Dev Ind Pharm. 1993;19:2399–471.

Forsyth AJ, Hutton S, Rhodes MJ. Effect of cohesive interparticle force on the flow characteristics of granular material. Powder Technol. 2002;126:150–4.

Reier GE, Shangraw RF. Microcrystalline cellulose in tableting. J Pharm Sci. 1966;55:510–4.

McKenna A, McCafferty DF. Effect of particle size on the compaction mechanism and tensile strength of tablets. J Pharm Pharmacol. 1982;34:347–51.

Roberts RJ, Rowe RC. The effect of the relationship between punch velocity and particle size on the compaction behaviour of materials with varying deformation mechanisms. J Pharm Pharmacol. 1986;38:567–71.

Podczeck F, Revesz P. Evaluation of the properties of microcrystalline and microfine cellulose powders. Int J Pharm. 1993;91:183–93.

Haware RV, Tho I, Bauer-Brandl A. Multivariate analysis of relationships between material properties, process parameters and tablet tensile strength for α-lactose monohydrates. Eur J Pharm Biopharm. 2009;73:424–31.

Sebhatu T, Ahlneck C, Alderborn G. The effect of moisture content on the compression and bond-formation properties of amorphous lactose particles. Int J Pharm. 1997;146:101–14.

Sebhatu T, Alderborn G. Relationships between the effective interparticulate contact area and the tensile strength of tablets of amorphous and crystalline lactose of varying particle size. Eur J Pharm Sci. 1999;8:235–42.

Hiestand EN. Tablet bond. I. A theoretical model. Int J Pharm. 1991;67:217–29.

Hiestand EN, Smith DP. Tablet bond. II. Experimental check of model. Int J Pharm. 1991;67:231–46.

Acknowledgments

The authors would like to thank The Finnish Centre for Nanocellulosic Technologies, Finland as well as Panu Lahtinen and Hanna-Mari Sinilehto, VTT, Finland for the preparation of trial materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kolakovic, R., Peltonen, L., Laaksonen, T. et al. Spray-Dried Cellulose Nanofibers as Novel Tablet Excipient. AAPS PharmSciTech 12, 1366–1373 (2011). https://doi.org/10.1208/s12249-011-9705-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-011-9705-z