Abstract

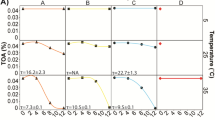

An area of increasing concern and scientific scrutiny is the potential contamination of drug products by leachables entering the product during manufacturing and storage. These contaminants may either have a direct safety impact on the patients or act indirectly through the alteration of the physicochemical properties of the product. In the case of biotherapeutics, trace amounts of metal contaminants can arise from various sources, but mainly from contact with stainless steel (ss). The effect of the various factors, buffer species, solution fill volume per unit contact surface area, metal chelators, and pH, on metal leachables from contact with ss over time were investigated individually. Three major metal leachables, iron, chromium, and nickel, were monitored by inductively coupled plasma–mass spectrometry because they are the major components of 316L ss. Iron was primarily used to evaluate the effect of each factor since it is the most abundant. It was observed that each studied factor exhibited its own effect on metal leachables from contact with ss. The effect of buffer species and pH exhibited temperature dependence over the studied temperature range. The metal leachables decreased with the increased fill volume (mL) per unit contact ss surface area (cm2) but a plateau was achieved at approximately 3 mL/cm2. Metal chelators produced the strongest effect in facilitating metal leaching. In order to minimize the metal leachables and optimize biological product stability, each formulation factor must be evaluated for its impact, to balance its risk and benefit in achieving the target drug product shelf life.

Similar content being viewed by others

References

Passerini A et al. Identifying cysteines and histidines in transition-metal-binding sites using support vector machines and neural networks. Proteins. 2006;65(2):305–16.

Uversky VN, Li J, Fink AL. Metal-triggered structural transformations, aggregation, and fibrillation of human alpha-synuclein. A possible molecular NK between Parkinson’s disease and heavy metal exposure. J Biol Chem. 2001;276(47):44284–96.

Markovic I. Challenges associated with extractables and/or leachables substances in therapeutic biologic protein products. Am Pharm Rev. 2006;9(6):20–7.

Bee JS et al. Precipitation of a monoclonal antibody by soluble tungsten. J Pharm Sci. 2009;98(9):3290–301.

International conference on harmonization of technical requirements for registration of pharmaceuticals for human use (ICH). Guideline for industry: impurities in new drug substances, ICH Q3A

CDER Guidance Document: container closure systems for packaging human drugs and biologics. 1999.

EMEA, Harmonized guideline (EMEA and health Canada) on the pharmaceutical quality of inhalation and nasal products. 2005.

ICH, International conference on harmonization of technical requirements for registration of pharmaceuticals for human use. Guideline for industry: Good manufacturing practices, ICH Q6A.

ICH, International conference on harmonization of technical requirements for registration of pharmaceuticals for human use. Guidance for industry: impurities in new drug substances, ICH Q3B.

Arbin A, Jacobsson S, Hanninen K, Hagman A, Ostelius J. Studies on contamination of intravenous solutions from PVC-bags with dynamic headspace GC-MS and LC-diode array techniques. J Pharm Sci. 1986;28:211–8.

Goydan R et al. High-temperature migration of antioxidants from polyolefins. Food Addit Contam. 1990;7(3):323–37.

Jenke D. Extractable/leachable substances from plastic materials used as pharmaceutical product containers/devices. PDA J Pharm Sci Technol. 2002;56(6):332–71.

Jenke D et al. Performance characteristics of an ion chromatographic method for the quantitation of citrate and phosphate in pharmaceutical solutions. J Chromatogr Sci. 2007;45(1):50–6.

Jenke D et al. Strategy for assessing the leachables impact of a material change made in a container/closure system. PDA J Pharm Sci Technol. 2005;59(6):360–80.

Jenke RD, Chess EK, Zietlow DC, Rabinow BE. Model for estimating the accumulation of solutes leaching from polymeric containers into parenteral solutions. Int J Pharm Sci. 1992;78:115–22.

Jenke RD, Chess EK, Jakubowski G. Modeling of the leachables impact on the engineering of parenteral product container systems. Int J Pharm. 1994;108:1–9.

Kim K, Rhee SG, Stadtman ER. Nonenzymatic cleavage of proteins by reactive oxygen species generated by dithiothreitol and iron. J Biol Chem. 1985;260(29):15394–7.

Reif OW, Solkner P, Rupp J. Analysis and evaluation of filter cartridge extractables for validation in pharmaceutical downstream processing. PDA J Pharm Sci Technol. 1996;50(6):399–410.

Sanga SV. Review of glass types available for packaging parenteral solutions. J Parenter Drug Assoc. 1979;33(2):61–7.

Jenke DR, Story J, Lalani R. Extractables/leachables from plastic tubing used in product manufacturing. Int J Pharm. 2006;315(1–2):75–92.

Nicholas K. Extractables and leachables determination: a systematic approach to select and qualify a container closure system for a pharmaceutical product. Am Pharm Rev. 2006;9(3):21–7.

Osterberg RE. Potential toxicity of extractables and leachables in drug product. Am Pharm Rev. 2005;8(2):64–7.

Taborsky CJ, Sheinin EB, Hunt DG. A critical approach to the evaluation of packaging components and the regulatory and scientific considerations in developing a testing strategy. Am Pharm Rev. 2006;9:146–50.

Allain L., Wang Q., Impact of package leachables on the stability of pharmaceutical products. Am Pharm Rev. 2007;10(4):38, 40, 42-44.

316/316L Stainless steel product data sheet. Cited 2007; available from: www.aksteel.com.

Waterman KC et al. Stabilization of pharmaceuticals to oxidative degradation. Pharm Dev Technol. 2002;7(1):1–32.

Zhou S, Zhang B, Sturm E, Teagarden D, Schoneich C, Kolhe P, et al. Comparative evaluation of disodium EDTA adn DTPA as iron chelators to prevent metal catalyzed destabilization of a therapeutic monoclonal antibody. J Pharm Sci. 2010;99(10):4239–50.

Rubinson, K.A., ed. Chemical Analysis. 1st ed. 1987, Little, Brown and Company, Boston.

Kolhe P, Amend SSE. Impact of freezing on pH of buffered solutions and consequences for monoclonal antibody aggregation. Biotech Progr. 2009. doi:10.1002/btpr.377.

Kocijan A, Milosev I, Pihlar B. The influence of complexing agent and proteins on the corrosion of stainless steels and their metal components. J Mater Sci Mater Med. 2003;14(1):69–77.

Jacobs A, Miles PM. Role of gastric secretion in iron absorption. Gut. 1969;10(3):226–9.

Acknowledgments

The 316L stainless steel coupons utilized in this study were supplied courtesy of Boehringer Ingelheim Pharma. We gratefully acknowledge Parag Kolhe (Biotherapeutic Pharmaceutical Science, Pfizer Inc.) for his help in calculating the probability factor using the JMP data analysis software and Bo Zhang (Biotherapeutic Pharmaceutical Science, Pfizer Inc.) for his help in analyzing the samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editors: Lavinia Lewis, Jim Agalloco, Bill Lambert, Russell Madsen, and Mark Staples

Rights and permissions

About this article

Cite this article

Zhou, S., Schöneich, C. & Singh, S.K. Biologics Formulation Factors Affecting Metal Leachables from Stainless Steel. AAPS PharmSciTech 12, 411–421 (2011). https://doi.org/10.1208/s12249-011-9592-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-011-9592-3