Abstract

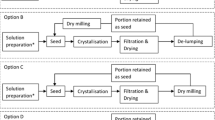

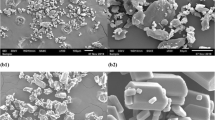

A novel experimental approach describing the integration of drug substance and drug production design using particle engineering techniques such as sonocrystallization, high shear wet milling (HSWM) and dry impact (hammer) milling were used to manufacture samples of an active pharmaceutical ingredient (API) with diverse particle size and size distributions. The API instability was addressed using particle engineering and through judicious selection of excipients to reduce degradation reactions. API produced using a conventional batch cooling crystallization process resulted in content uniformity issues. Hammer milling increased fine particle formation resulting in reduced content uniformity and increased degradation compared to sonocrystallized and HSWM API in the formulation. To ensure at least a 2-year shelf life based on predictions using an Accelerated Stability Assessment Program, this API should have a D [v, 0.1] of 55 μm and a D [v, 0.5] of 140 μm. The particle size of the chief excipient in the drug product formulation needed to be close to that of the API to avoid content uniformity and stability issues but large enough to reduce lactam formation. The novel methodology described here has potential for application to other APIs.

Similar content being viewed by others

References

Yu L, Lionberger R, Raw S, D’Costa R, Wu H, Hussain A. Adv Drug Deliv Rev. 2004;56:349–56.

Fujiwara M, Nagy Z, Chew J, Braatz R. J Process Control. 2005;15:493–504.

Ulrich J, Jones M. Chem Eng Res Des. 2004;82:567–1570.

Jones A. Crystallization Process Systems. Amsterdam: Elsevier; 2002. p. 58–79.

Beckmann W, Buddle U. Encyclopaedia of Separation Science. Amsterdam: Elsevier; 2007. p. 3729–38.

Iacocca R, Burcham C, Hilden L. J Pharm Sci. 2009;99:51–75.

Docherty R, Kougoulos E, Horspool KR. Materials science and crystallization: the interface of drug substance and drug product. Am Pharm Rev. 2009;12:39–46.

Nanev C. Cryst Growth Des. 2007;7:1533–40.

McPherson A, Malkin AJ, Kuznetsov YG, Koszelak S, Wells M, Jenkins G, et al. J Cryst Growth. 1999;196:572–86.

Hajratwalav BR. J Pharm Sci. 1982;2:188–90.

Lee I, Starbuck C, Lindemann C, Variankaval N. Process Chemistry & Engineering, 2006; April 10–12.

Ruecroft G, Hipkiss D, Ly T, Maxted N, Cains P. Org Process Res Dev. 2005;9:923–32.

Guo Z, Zhang M, Li H, Wang J, Kougoulos E. J Cryst Growth. 2005;273:555–63.

Cains P, Martin P, Price C. Org Process Res Dev. 1998;2:34–48.

Li H, Wang J, Bao Y, Guo Z, Zhang M. J Cryst Growth. 2003;247:192–8.

Louhi-Kultanen M, Karjalainen M, Rantanen J, Huhtanen M, Kallas J. Int J Pharm. 2006;320:23–9.

Luque de Castro M, Priego-Capote F. Ultrason Sonochem. 2007;14:717–24.

Yalkowsky S, Bolton S. Pharm Res. 1990;7:962.

Mullarney M, Leyva N. Pharm Tech, 2009;March 1–6.

Narayan P, Hancock B. Mat Sci Eng. 2003;A355:24.

Sun C, Hou H, Gao P, Ma C, Medina C, Alvarez J. J Pharm Sci. 2008;98:239–47.

Johnson K, Swindell A. Pharm Res. 1996;13:1795.

Taylor L, Papadopoulos D, Dunn P, Bentham A, Dawson N, Mitchell J, et al. Org Process Res Dev. 2004;8:674.

Lui L, Marziano I, Bentham A, Litster J, White E, Howes T. Int J Pharm. 2008;362:109–17.

Shekunov B, Chattopadhyay P, Tong H, Chow A. Pharm Res. 2007;23:203.

Roberts R, Rowe R. Intelligent Software for Product Formulation. New York: Taylor and Francis; 1998.

Deng T, Paul KA, Bradley MSA, Immins L, Preston C, Scott JF, et al. Powder Technol. 2010;12(203):354–8.

Figueroa I, Li H, McCarthy J. Powder Technol. 2009;3(195):203–12.

Abou-Chakra H, Tuzun U, Bridle I, Leaper M, Bradley MSA, Reed AR. Adv Powder Technol. 2003;14(2):167–76.

Hintz RJ, Johnson KC. Int J Pharm. 1989;51:9–17.

Rohrs BR, Amidon GE, Meury RH, Secreast PJ, King HM, Skoug CJ. J Pharm Sci. 2006;5:1049–59.

Waterman KC, Carella AJ, Gumkowski MJ. Pharm Res. 2007;24:780–90.

Acknowledgements

The authors would like to thank Neil Dawson for particle size distribution characterisation support and Lisa Taylor for supporting dry milling studies. We also acknowledge Florence Colin and Sally Grieb for analytical assistance and Kate Boxell for conducting the segregation studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research project is funded by the Netherlands Organization for Scientific Research (NWO, The Hague, project number: 411-02-163)

Rights and permissions

About this article

Cite this article

Kougoulos, E., Smales, I. & Verrier, H.M. Towards Integrated Drug Substance and Drug Product Design for an Active Pharmaceutical Ingredient Using Particle Engineering. AAPS PharmSciTech 12, 287–294 (2011). https://doi.org/10.1208/s12249-011-9582-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-011-9582-5