Abstract

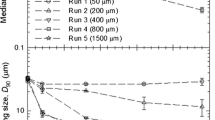

The air-jet and ball-mill are frequently used in fine micronization of active pharmaceutical ingredients to the order of 1–5 μm, which is important for increasing dissolution rates, and also for pulmonary delivery. In this study, we investigated the ability of air-jet and ball-mill to achieve adequate micronization on the lab scale using a model soft material, Pluronic® F-68. Material mechanical properties were characterized using the nanometer 600. Pluronic® F-68 was ball-milled in a micro-mill at different material weights and durations in liquid nitrogen vapor. In comparison, a lab scale air-jet mill was used at various milling parameters according to a full factorial design, where the response factors were particle yield and particle size distribution, which was analyzed using laser diffraction and scanning electron microscopy. The yield achieved with the micro-ball mill was 100% but was ~80% for the air-jet mill, which reduced the size of Pluronic® F-68 from 70 μm to sizes ranging between 23–39 μm median diameters. Ball milling produced particles less than 10 μm after 15 min. Although air-jet milling proved capable of particle size reduction of the relatively soft material Pluronic® F-68, limitations to the lower size range achievable were observed. The feed rate of the material into the air jet mill was a significant factor and slower feed rates lead to smaller sizes by allowing more time for particle collisions and subsequent particle breakage to occur. Micro-ball milling under cold condition was more successful at achieving a lower range particle size reduction of soft materials.

Similar content being viewed by others

References

Posti J, Katila K, Kostianen T. Dissolution rate limited biovailability of flutamide, and in vitro–in vivo correlation. Eur J Pharm Biopharm. 2000;49(1):35–9.

Waterman CK, Sutton CS. A computational model for particle size influence on drug absorption during controlled-release colonic delivery. J Control Release. 2003;86(2–3):293–304.

Zeng XM, Martin GP, Tee SK, Abu A. Effects of particle size and adding sequence of fine lactose on the deposition of salbutamol sulphate from a dry powder formulation. Int J Pharm. 1999;133–44.

Steckel H, Müller B. In vitro evaluation of dry powder inhalers II: influence of carrier particle size and concentration on in vitro deposition. Int J Pharm. 1997;154(1):31–7.

Shoyele AS, Slowey A. Prospects of formulating proteins/peptides as aerosols for pulmonary drug delivery. Int J Pharm. 2006;314(1):1–8.

Gilani K, Najafabadi AR, Barghi M, Rafiee-Tehrani M. Aerosolisation of beclomethasone dipropionate using spray dried lactose/polyethylene glycol carriers. Eur J Pharm Biopharm. 2004;58(3):595–606.

Finlay WH, Stapleton KW, Zuberbuhler P. Fine particle fraction as measure of mass depositing in the lung inhalation of nearly isotonic nebulized aerosols. J Aerosol Sci. 1997;28(7).

Hickey A, Martonen BT, Yang Y. Theoretical relationship of lung deposition to the fine particle fraction of inhalation aerosols. Pharm Acta Helv. 1996;71(3):185–90.

Newman PS, Wilding RI, Hirst HP. Human lung deposition data: the bridge between in vitro and clinical evaluations for inhaled drug products. Int J Pharm. 2000;208(1–2):49–60.

Irngartinger M, Camuglia V, Damm M, Goede J, Frijlink HW. Pulmonary delivery of therapeutic peptides via dry powder inhalation: effects of micronisation and manufacturing. Eur J Pharm Biopharm. 2004;58(1):7–14.

Vatsaraj BN, Gao D, Kowalski LD. Optimization of the operating conditions of a lab scale aljet mill using lactose and sucrose: a technical note. AAPS PharmSciTech. 2003;4(2):p. Article 27.

Tanaka T, Kanda Y. Crushing and grinding. In: Masuda H, Higashitani K, Yoshida H, editors. Powder technology handbook. 3rd ed. New York: CRC Taylor and Francis; 2006.

Gilvarry JJ. Fracture of brittle solids, I. J Appl Phys. 1961;32:391–9.

Gaudin AM, Meloy TP. Trans AIME. 1962;223:43–51.

Broadbent SR, Calcott TG. Coal breakage processes:l a new analysis of coal breakage processes. J Inst Fuel. 1956;29:524–8.

Chujo K. Kagaku Kougaku Kagakukikai. 1949;7:1–83.

Taylor LJ, Papadopoulos DG, Dunn PJ, Bentham AC, Mitchell JC, Snowden MJ. Mechanical characterisation of powders using nanoindentation. Powder Technol. 2004;143–144:179–85.

Hancock BC, Clas SD, Christensen K. Micro-scale measurement of the mechanical properties of compressed pharmaceutical powders. 1: the elasticity and fracture behaviour of microcrystalline cellulose. Int J Pharm. 2000;209(1–2):27–35.

York P, Bassam F, Rowe RC, Roberts RJ. Fracture mechanics of microcrystalline cellulose powders. Int J Pharm. 1990;66:143–8.

Batrakova EV, Li S, Li Y, Alakhov VY, Kabanov AV. Effect of pluronic P85 on ATPase activity of drug efflux transporters. Pharm Res. 2004;12:2226–33.

Batrakova EV, Kabanov AV. Pluronic block copolymers: evolution of drug delivery concept from inert nanocarriers to biological response modifiers. J Control Release. 2008;130(2):98–106.

Xiong XY, Tam KC, Gan LH. Polymeric nanostructures for drug delivery applications based on Pluronic copolymer systems. J Nanosci Nanotechnol. 2006;6(9–10):2638–50.

El-Sherbiny IM, McGill S, Smyth HD. Swellable microparticles as carriers for sustained pulmonary drug delivery. J Pharm Sci. 2010;99(5):2343–56.

Yang YT, Chen CT, Yang JC, Tsai T. Spray-dried microparticles containing polymeric micelles encapsulating hematroporphyrin. AAPS J. 2010;12(2):138–46.

Garmise RJ, Mar K, Crowder TM, Hwang CR, Ferriter M, Huang J, et al. Formulation of a dry powder influenza vaccine for nasal delivery. AAPS PharmSciTech. 2006;10(7):E19.

Chieng N, Rades T, Saville D. Formation and physical stability of the amorphous phase of ranitidine hydrochloride polymorphs prepared by cryo-milling. Eur J Pharm Biopharm. 2008;68(3):771–80.

Shaik MS, Haynes A, McSween J, Ikediobi O, Kanikkannan N, Singh M. Inhalation delivery of anticancer agents via HFA-based metered dose inhaler using methotrexate as a model drug. J Aerosol Med. 2002;15(3):261–70.

Duncan-Hewitt WC, Weatherley GC. Evaluating the hardness, Young's modulus, and fracture toughness of some pharmaceutical crystals using microindentation techniques. J Mater Sci Lett. 1989;8(11):1350–2.

Zugner S, Marquardt K, Zimmermann I. Influence of nanomechanical crystal properties on the comminution process of particulate solids in spiral jet mills. Eur J Pharm Biopharm. 2006;62:194–201.

Liao X, Wiedmann TS. Characterization of pharmaceutical solids by scanning probe microscopy. J Pharm Sci. 2004;93(9):2250–8.

Chen Y, Ding Y, Papadopoulos DG, Ghadiri M. Energy-based analysis of milling α-lactose monohydrate. J Pharm Sci. 2004;93(4):886–95.

Acknowledgments

The authors would like to acknowledge that a portion of this work was performed by them when working at the College of Pharmacy, University of New Mexico, USA. The authors would also like to thank Dr Marwan Al-Haik at Department of Mechanical Engineering, School of Engineering, University of New Mexico, USA, for his help in using the nanotester 600 and determining the results.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saleem, I.Y., Smyth, H.D.C. Micronization of a Soft Material: Air-Jet and Micro-Ball Milling. AAPS PharmSciTech 11, 1642–1649 (2010). https://doi.org/10.1208/s12249-010-9542-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-010-9542-5