Abstract

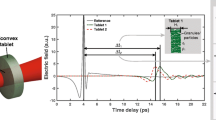

A method was developed that enables in-line analysis of film coating thickness on tablets during a pan coating operation. Real-time measurements were made using a diffusereflectance near-infrared (NIR) probe positioned inside the pan during the coating operation. Real-time spectra of replicate batches were used for modeling film growth. Univariate analysis provided a simple method for in-line monitoring of the coating process using NIR data. An empirical geometric 2-vector volumetric growth model was developed, which accounts for differential growth on the face and band regions of biconvex tablets. The thickness of the film coat was determined by monitoring the decrease of absorption bands characteristic of a component of the tablet core and monitoring the increase of bands characteristic of a component in the coating material. There was good correlation between values estimated from the NIR data and the measured tablet volumetric growth. In-line measurements allow the coating process to be stopped when a predetermined tablet coating thickness is achieved.

Similar content being viewed by others

References

FDA Draft Guidance.Guidance for Industry PAT-A Framework for Innovative Pharmaceutical Manufacturing and Quality Assurance. Washington, DC: Food and Drug Administration, Center for Drug Evaluation and Research (CDER). August 2003.

Guma NC, Kale K, Morris KR. Investigation of film curing stages by dielectric analysis and physical characterization.J Pharm Sci. 1997;86:329–334.

Wildfong PLD, Samy AS, Corfa J, Peck GE, Morris KR. Accelerated fluid bed drying using NIR monitoring and phenomenological modeling: Method assessment and formulation suitability.J Pharm Sci. 2002;91:631–639.

Morris KR, Stowell JG, Byrn SR, Placette AW, Davis TD, Peck GE. Accelerated fluid bed drying using NIR monitoring and phenomenological modeling.Drug Dev Ind Pharm. 2000;26:985–988.

De Maesschalck R, Sanchez FC, Massart DL, Doherty P, Hailey P. On-line monitoring of powder blending with near-infrared spectroscopy.Appl Spectrosc. 1998;52:725–731.

El-Hagrasy AS, Morris HR, D'Amico F, Lodder RA, Drennen JK 3rd. Near-infrared spectroscopy and imaging for the monitoring of powder blend homogeneity.J Pharm Sci. 2001;90:1298–1307.

Blanco M, Bano RG, Bertran E. Monitoring powder blending in pharmaceutical processes by use of near infrared spectroscopy.Talanta. 2002;56:203–212.

Kirsch JD, Drennen JK. Determination of film-coated tablet parameters by near-infrared spectroscopy.J Pharm Biomed Anal. 1995;13:1273–1281.

Ufret C, Morris K. Modeling of powder blending using on-line near-infrared measurements.Drug Dev Ind Pharm. 2001;27:719–729.

Andersson M, Josefson M, Langkilde FW, Wahlund KG. Monitoring of a film coating process for tablets using near infrared reflectance spectrometry.J Pharm Biomed Anal. 1999;20:27–37.

Andersson M, Folestad S, Gottfries J, Johansson MO, Josefson M, Wahlund KG. Quantitative analysis of film coating in a fluidized bed process by in-line NIR spectrometry and multivariate batch calibration.Anal Chem. 2000;72:2099–2108.

Callis JB, Illman DL, Kowalski BR. Process analytical-chemistry.Anal Chem. 1987;59:624–630.

Blaser WW, Bredeweg RA, Harner RS, et al. Process analyticalchemistry.Anal Chem. 1995;67:R47-R70.

Hassell DC, Bowman EM. Process analytical chemistry for spectroscopists.Appl Spectrosc. 1998;52:18A-29A.

Sekulic SS, Ward HW, Brannegan DR, et al. On-line monitoring of powder blend homogeneity by near-infrared spectroscopy.Anal Chem. 1996;68:509–513.

Wargo DJ, Drennen JK. Near-infrared spectroscopic characterization of pharmaceutical powder blends.J Pharm Biomed Anal. 1996;14:1415–1423.

Hailey PA, Doherty P, Tapsell P, Oliver T, Aldridge PK. Automated system for the on-line monitoring of powder blending processes using near-infrared spectroscopy. I. System development and control.J Pharm Biomed Anal. 1996;14:551–559.

Aldridge PK, Kelly JJ, Callis JB, Burns DH. Noninvasive monitoring of bulk-polymerization using short-wavelength near-infrared spectroscopy.Anal Chem. 1993;65:3581–3585.

Kirsch JD, Drennen JK. Near-infrared spectroscopic monitoring of the film coating process.Pharm Res.. 1996;13:234–237.

Rantanen J, Lehtola S, Ramet P, Mannermaa JP, Yliruusi J. On-line monitoring of moisture content in an instrumented fluidized bed granulator with a multi-channel NIR moisture sensor.Powder Technol. 1998;99:163–170.

Obara S, McGinity JW. Influence of processing variables on the properties of free films prepared from aqueous polymeric dispersions by a spray technique.Int J Pharm. 1995;126:1–10.

Aulton ME, Twitchell AM, Hogan JE: Physical properties of hpmc solutions and their role in the film coating process and the quality of the coated product. In: McGinity JW, ed.Aqueous Polymeric Coatings for Pharmaceutical Dosage Forms. 2nd ed. New York, NY: Marcel Dekker; 1997.

Mark H, Workman J. Derivatives in spectroscopy. I. The behavior of the derivative.Spectroscopy. 2003;18:32–37.

Munzel K. Recent advances in pharmaceutical coating. 1963;38:65–85, 129–146.

Kern WF, Bland JR, Spherical segment. In:Solid Mensuration With Proofs. 2nd ed. New York, NY: Wiley, 1948;97–102.

Harris JW, Stocker H. Spherical segment (spherical cap). In:Handbook of Mathematics and Computational Science. New York, NY: Springer-Verlag; 1998;107.

Rowe RC. Predicting film thickness on film coated tablets.Int J Pharm. 1996: 133:253–256.

Rowe RC. Materials used in the film coating of oral dosage forms. In: Florence AT, ed.Critical Reports on Applied Chemistry. Oxford, United Kingdom: Blackwell Scientific Publications; 1984;1–36.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: September 20, 2005

Rights and permissions

About this article

Cite this article

Pérez-Ramos, J.D., Findlay, W.P., Peck, G. et al. Quantitative analysis of film coating in a pan coater based on in-line sensor measurements. AAPS PharmSciTech 6, 20 (2005). https://doi.org/10.1208/pt060120

Received:

Accepted:

DOI: https://doi.org/10.1208/pt060120