Abstract

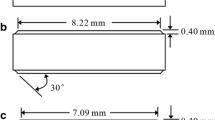

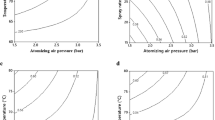

The purpose of this study was to evaluate tablet mixing within side-vented coating equipment by assessing the development of color uniformity during coating. A colorimetric method was used to evaluate the time for uniform coating for different mixing baffle systems at different scales of equipment. The influence of tablet size was also determined. The inclusion of rabbit ear baffles in the small-scale equipment reduced the time to achieve color uniformity by 20 minutes. The design of baffle influenced the time for uniform color with a mixing efficiency rank order of tubular > ploughshare > rabbit ear. Upon scale-up, the efficiency of mixing seen at development scale remained equivalent in terms of the influence of baffle design. The study into the influence of tablet size revealed the importance that the total batch surface area has on the time taken to achieve color uniformity, with 7-mm diameter tablets having a higher surface area for an equivalent volume of product and taking 15 to 20 minutes longer to achieve color uniformity than 16-mm diameter tablets.

Similar content being viewed by others

References

Maclean AG. Scale-up of a novel application of film coating to an oramucosal delivery system: an assessment of equipment performance. In: 20th Pharmaceutical Technology Conference Abstracts, 2001; 24–26 April, 2001; Liverpool, UK; 129.

Fourman GL, Hines CW, Hritsko RS. Assessing the uniformity of aqueous film coatings applied to compressed tablets. Pharm Tech. 1995;19(3):70–76.

Leaver TM, Shannon HD, Rowe RC. A photometric analysis of tablet movement in a side-vented perforated drum (Accelacota). J Pharm Pharmacol. 1985;37:17–21.

Wilson KE, Crossman E. The influence of tablet shape and pan speed on intra-tablet film coating uniformity. Drug Dev Ind Pharm. 1997;23:1239–1243.

Tobiska S, Kleinebudde P. A simple method for evaluating the mixing efficiency of a new pan coater. Int J Pharm. 2001;224:141–149.

Bhagwant D, Rege BD, Gawel J, Kou JH. Identification of critical process variables for coating actives onto tablets via statistically designed experiments. Int J Pharm. 2002;237:87–94.

Signorino CA, Forcellini LJ. Evaluating the uniformity of aqueous film coating. Pharm Tech. 1996;20:48–53.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smith, G.W., Macleod, G.S. & Fell, J.T. Mixing efficiency in side-vented coating equipment. AAPS PharmSciTech 4, 37 (2003). https://doi.org/10.1208/pt040337

Received:

Accepted:

DOI: https://doi.org/10.1208/pt040337