Abstract

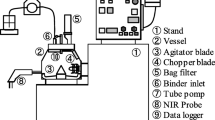

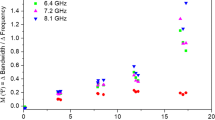

This study assesses the fluidized bed granulation process for the optimization of a model formulation using in-line near-infrared (NIR) spectroscopy for moisture determination. The granulation process was analyzed using an automated granulator and optimization of the verapamil hydrochloride formulation was performed using a mixture design. The NIR setup with a fixed wavelength detector was applied for moisture measurement. Information from other process measurements, temperature difference between process inlet air and granules (Tdiff), and water content of process air (AH), was also analyzed. The application of in-line NIR provided information related to the amount of water throughout the whole granulation process. This information combined with trend charts of Tdiff and AH enabled the analysis of the different process phases. By this means, we can obtain in-line documentation from all the steps of the processing. The choice of the excipient affected the nature of the solid-water interactions; this resulted in varying process times. NIR moisture measurement combined with temperature and humidity measurements provides a tool for the control of water during fluid bed granulation.

Similar content being viewed by others

References

Callis J, Illman D, Kowalski B. Process analytical chemistry. Anal Chem. 1987;59:624A-637A.

Beebe K, Blaser W, Bredeweg R, et al. Process analytical chemistry. Anal Chem. 1993;65:199R-216R.

Zografi G. States of water associated with solids. Drug Dev Ind Pharm. 1988;14:1905–1926.

Brittain H. Methods for the characterization of polymorphs and solvates. In: Brittain H, ed. Polymorphism in pharmaceutical solids. 1st ed. New York: Marcel Dekker Inc; 1999:227–278.

Schaefer T, Wørts O. Control of fluidized bed granulation III. Effect of inlet air temperature and liquid flow rate on granule size and size distribution. Control of moisture content of granules in the drying phase. Arch Pharm Chem Sci. 1978;6:1–13.

Abberger T, Raneburger J, Egermann H. Instrumentation of laboratory-scale fluid-bed granulator for critical moisture content and of free moisture. Sci Pharm. 1996;64:255–262.

Wöstheinrich K, Schmidt P. Evaluation and validation of a fully instrumented Hüttlin HKC 05-TJ laboratory-scale fluidized bed granulator.Drug Dev Ind Pharm.2000;26:621–633.

Workman J, A review of process near infrared spectroscopy: 1980–1994. J Near Infrared Spectrosc. 1993;1:221–245.

Axon T, Brown R, Hammond S, Maris S, Ting F. Focusing near infrared spectroscopy on the business objectives of modern pharmaceutical production. J Near Infrared Spectrosc. 1998;6:A13-A19.

Kamat MS, Lodder RA, DeLuca PP. Near-infrared spectroscopic determination of residual moisture in lyophilized sucrose through intact glass vials.Pharm Res.1989;6:961–965.

Osborne BG, Fearn T, Hindle PH. In: Practical NIR Spectroscopy with Applications in Food and Beverage Industry Analysis. 2nd ed. Harlow, UK: Longman; 1993:227.

Watano S, Terashita K, Miyanami K. Development and application of infrared moisture sensor to complex granulation. Bull Univ Osaka Pref, Series A. 1990;39(2):187–197.

White J. On-line moisture detection for a microwave vacuum dryer.Pharm Res.1994;11:728–732.

Frake P, Greenhalgh D, Grierson S, Hempenstall J, Rudd D. Process control and end-point determination of a fluid bed granulation by application of near infra-red spectroscopy. Int J Pharm. 1997;151:75–80.

Goebel S, Steffens K. Online-messung der Produktfeuchte und Korngröße in der Wirbelschnicht mit der Nah-Infrarot-Spektroskopie. Pharm Ind. 1998;60:889–895.

Rantanen J, Lehtola S, Rämet P, Mannermaa J-P, Yliruusi J. On-line monitoring of moisture content in an instrumented fluidized bed granulator with a multichannel NIR moisture sensor. Powder Technol. 1998;99:163–170.

Luukkonen P, Rantanen J, Mäkelä K, Räsänen E, Tenhunen J, Yliruusi J. Characterization of silicified microcrystalline cellulose and a-lactose monohydrate wet masses using near infrared spectroscopy.Pharm Dev Technol.2001;6:1–9.

Räsänen E, Rantanen J, Jørgensen A, Karjalainen M, Paakkari T, Yliruusi J. Novel identification of pseudopolymorphic changes of theophylline during wet granulation using near infrared spectroscopy.J Pharm Sci.2001;90:389–396.

Iwamoto M, Uozumi J, Nishinari K. Preliminary investigation of the state of water in foods by near infrared spectroscopy. Budapest, Hungary. Intl NIR/NIT Conference; 1987:3–12.

Delwiche S, Pitt R, Norris K. Examination of starch-water and cellulose-water interactions with near infrared (NIR) diffuse reflectance spectroscopy. Starch/Stärke. 1991;43:415–422.

Rantanen J, Känsäkoski M, Suhonen J, et al. Next generation fluidized bed granulator automation. AAPS PharmSciTech 2000;1(2) Available from:http://www.aapspharmaceutica.com/scientificjournals/ pharmscitech/volume1issue2/014/manuscript.htm

Rantanen J, Räsänen E, Mannermaa J-P, Yliruusi J. In-line moisture measurement during granulation with a four wavelength near infrared sensor: an evaluation of particle size and binder effects.Eur J Pharm Biopharm.2000;50:271–276.

Rantanen J, Laine S, Antikainen O, Mannermaa J-P, Simula O, Yliruusi, J. Visualization of pharmaceutical unit operations using self-organizing maps (SOM).J Pharm Biomed Anal.2001;24:343–352.

Morris K, Stowell J, Byrn S, Placette A, Davis T, Peck G. Accelerated fluid bed drying using NIR monitoring and phenomenological modeling.Drug Dev Ind Pharm.2000;26:985–988.

Watano S. Mechanism and control of granule growth in fluidized bed granulation [dissertation]. Osaka, Japan: College of Engineering, University of Osaka; 1995.

Watano S, Takashima H, Sato Y, Miyanami K, Yasutomo T. IR absorption characteristics of an IR moisture sensor and mechanism of water transfer in fluidized bed granulation. Adv Powder Technol. 1996;7:279–289.

Miwa A, Yajima T, Itai S. Prediction of suitable amount of water addition for wet granulation.Int J Pharm.2000;195:81–92.

Schmidt C, Kleinebudde P. Influence of the granulation step on pellets prepared by extrusion/spheronization. Chem Pharm Bull. 1999;47:405–412.

Author information

Authors and Affiliations

Additional information

Published: October 17, 2001.

Rights and permissions

About this article

Cite this article

Rantanen, J., Jørgensen, A., Räsänen, E. et al. Process analysis of fluidized bed granulation. AAPS PharmSciTech 2, 21 (2001). https://doi.org/10.1208/pt020421

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/pt020421