Abstract

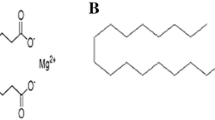

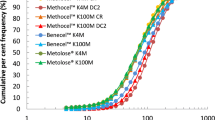

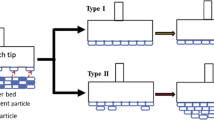

This study evaluated tableting compression by using internal and external lubricant addition. The effect of lubricant addition on the enzymatic activity of trypsin, which was used as a model drug during the tableting compression process, was also investigated. The powder mixture (2% crystalline trypsin, 58% crystalline lactose, and 40% microcrystalline cellulose) was kneaded with 5% hydroxypropyl cellulose aqueous solution and then granulated using an extruding granulator equipped with a 0.5-mm mesh screen at 20 rpm. After drying, the sample granules were passed through a 10-mesh screen (1680 μm). A 200-mg sample was compressed by using 8-mm punches and dies at 49, 98, 196, or 388 MPa (Mega Pascal) at a speed of 25 mm/min. The external lubricant compression was performed using granules without lubricant in the punches and dies. The granules were already dry coated by the lubricant. In contrast, the internal lubricant compression was performed using sample granules (without dry coating) containing 0.5% lubricant. At 98 MPa, for example, the compression level using the external lubricant addition method was about 13% higher than that for internal addition. The significantly higher compressing energy was also observed at other MPas. By comparison, the friction energy for the external addition method calculated based on upper and lower compression forces was only slightly larger. The hardness of tablets prepared using the internal addition method was 34% to 48% lower than that for the external addition method. The total pore volume of the tablet prepared using the external addition method was significantly higher. The maximum ejection pressure using the no-addition method (ie, the tablet was prepared using neither dry-coated granules nor added lubricant) was significantly higher than that of other addition methods. The order was as follows: no addition, external addition, and then internal addition. The ejection energy (EE) for internal addition was the lowest; for no addition, EE was the highest. In the dissolution test, the tablets obtained using external addition immediately disintegrated and showed faster drug release than those prepared using internal addition. This result occurred because the water penetration rate of the tablet using the external addition was much higher. The trypsin activity in tablets prepared using the external addition method was significantly higher than that produced using the internal addition method at the same pressure. All these results suggest that the external addition method might produce a fast-dissolution tablet. Because the drug will be compressed using low pressure only, an unstable bulk drug may be tableted without losing potency.

Similar content being viewed by others

References

Nelson E, Naqvi SM, Busse LW, Higuchi T. The physics of tablet compression IV: relationship of ejection, and upper and lower punch pressures during compressional process: application of measurements of comparison of tablet lubricants. J Am Pharm Assoc. 1954;43:596–602.

Augsburger LL, Shangraw RF. Effect of glidants in tableting. J Pharm Sci. 1966;55:413–418.

Knoechel EL, Sperry CC, Lintner CJ. Instrumented rotary tablet machine II, evaluation and typical applications in pharmaceutical research development, and production studies. J Pharm Sci. 1967;56:116–130.

Strickland WA, Nelso E, Busse LW, Higuchi T. The physics of tablet compression IX: fundamental aspects of tablet lubrication. J Am Pharm Assoc Sci Ed. 1956;45:51–55.

Bog U, Moldenhauer H. Zur Herstellung und Prufung von Tabletten. Pharm Ind. 1965;27:6–13.

Kikuta J, Kitamori N. Effect of mixing time on the lubricating properties of magnesium stearate and the final characteristics of the compressed tablet. Drug Dev Ind Pharm. 1994;20:343–355.

Chowhan ZT, Chi LH. Drug-excipient interactions resulting from powder mixing IV: role of lubricants and their effect on in-vitro dissolution. J Pharm Sci. 1986;75:542–545.

Chowhan ZT, Chi LH. Drug-excipient interactions resulting from powder mixing V: role of sodium lauryl sulfate. Int J Pharm. 1986;60:61–78.

Shah AC, Mlodozeniec AR. Mechanism of surface lubrication: influence of duration of lubricant excipient mixing on processing characteristics of powders and properties of compressed tablets. J Pharm Sci. 1977;66:1377–1382.

Otsuka M, Gao J, Matsuda Y. Effects of mixer and mixing time on the pharmaceutical properties of theophylline tablets containing various kinds of lactose as diluents. Drug Dev Ind Pharm. 1993;19:333–348.

Ogawa Y. Japanese Patent, Kokoku, 41-11273.

Morimoto K, Watanabe Y, Sanada K, Miwa T, Masada T, Japanese Patent, Koukai, 7-124231.

Gruber P, Glasel VI, Kingelholler W, Liske T. Direct lubrication of tablet tools, a contribution to the optimization of tablet manufacture. Drugs Made in Germany. 1991;34:24–30.

Morii M, Sano A, Takeguci N, Horokoshi I. Studies on inactivation of alkaline protease by tableting. Yakugaku Zasshi. 1973;93:300–303.

Horikoshi I, Takeguchi N, Morii M. Estimation of stress distribution in the convex type tablet using specific enzyme activity as parameter. Chem Pharm Bull. 1973;21:2136–2140.

Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem. 1976;72:248–254.

US Pharmacopeail Convention, Inc. United States Pharmacopoeia. 23rd ed. Rockville, MD: US Pharmacopeial Convention, Inc; 1995:1611–1612.

Takayama K, Nambu N, Nagai T. Factors affecting the dissolution of indomethacin dispersed in various water-soluble polymers. Chem Pharm Bull. 1982;30:673–678.

Joinen MJ, Juslin MJ. On frictional work at the die wall during tablet compression. Farm Aikak. 1974;83:1–8.

Tanigawara Y, Yamakoka K, Nakagawa T, Uno T. Moment analysis for the separation of mean in vivo disintegration, dissolution, absorption, and disposition time of ampicillin products. J Pharm Sci. 1982;71:1129–1133.

Washburn EW. The dynamics of capillary flow. Am Phys Soc. 1921;17:374–375.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: July 11. 2001

Rights and permissions

About this article

Cite this article

Otsuka, M., Sato, M. & Matsuda, Y. Comparative evaluation of tableting compression behaviors by methods of internal and external lubricant addition: Inhibition of enzymatic activity of trypsin preparation by using external lubricant addition during the tableting compression process. AAPS PharmSci 3, 20 (2001). https://doi.org/10.1208/ps030320

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/ps030320