Abstract

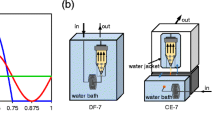

The hydrodynamics within the United States Pharmacopeia Apparatus 2 have been shown to be highly non-uniform with a potential to yield substantial variability in dissolution rate measurements. Through the use of readily available engineering tools, several geometric modifications to the device were evaluated in this study. Specifically, we examined the influence of impeller clearance, agitator type (radial and axial), and vessel geometry (PEAK vessel) on the fluid flow properties and their relation to measured dissolution rates. Increasing the impeller clearance was observed to exacerbate the heterogeneity in shear and would likely result in greater variability in dissolution measurements. Altering the impeller type was shown to yield changes in the hydrodynamic behavior; however, the overall properties and problems with the test remain the same. Use of the PEAK vessel was observed to reduce shear heterogeneity in the regions where tablets are most likely to visit during testing; however, higher shear rates may result in the inability to discriminate between true differences in dissolution rates.

Similar content being viewed by others

References

Banakar UV.Pharmaceutical Dissolution Testing. Vol 49. New York, NY: Marcel Dekker Inc; 1992.

Cox DC, Furman WB. Systematic error associated with Apparatus 2 of theUSP dissolution test I: effects of physical alignment of the dissolution apparatus.J Pharm Sci. 1982;71:451–452.

Moore TW, Hamilton JF, Kerner CM. Dissolution testing: limitations of theUSP prednisone and salicylic acid calibrator tablets.Pharmaceutical Forum. 1995;21:1387–1396.

Qureshi SA, McGilveray IJ. Typical variability in drug dissolution testing: study withUSP and FDA calibrator tablets and a marketed drug (Glibenclamide) product.Eur J Pharm Sci. 1999;7:249–258.

Qureshi SA, Shabnam J. Cause of high variability in drug dissolution testing and its impact on setting tolerances.Eur J Pharm Sci. 2001;12:271–276.

FDCReports. Recalls prompted by FDA on the increase.The Gold Sheet. 2001;35:1–19.

FDCReports. Counterfeits pose special recall challenge.The Gold Sheet. 2002;36:1–26.

FDCReports. Spike in potency-related problems contributes to overall rise in 2002 recalls.The Gold Sheet. 2003;37:1–20.

Levy G, Leonards JR, Procknal JA. Development of in vitro dissolution tests which correlate quantitatively with dissolution ratelimited drug absorption in man.J Pharm Sci. 1965;54:1719–1722.

Hamlin WE, Nelson E, Ballard BE, Wagner JG. Loss of sensitivity in distinguishing real differences in dissolution rates due to increasing intensity of agitation.J Pharm Sci. 1962;51:432–435.

Kukura J, Baxter JL, Muzzio FJ. Shear distribution and variability in the USP Apparatus 2 under turbulent conditions.Int J Pharm. 2004;279:9–17.

Beckett AH, Quach TT, Kurs GS. Improved hydrodynamics forUSP Apparatus 2.Diss Tec. 1996;3:7–18.

Collins CC, Nair RR. Comparative evaluation of mixing dynamics inUSP Apparatus 2 using standardUSP vessels and PEAK vessels.Diss Tech. 1998;5:17–21.

Johnson K, Bittorf KJ. Validating the Galerkin Least-Squares Finite Element Methods in predicting mixing flows in stirred tank reactors. Paper presented at: The 10th Annual Conference of the CFD Society of Canada, Proceedings; June 9–11, 2002; Windsor, Ontario.

Zalc JM.Computational Fluid Dynamics (CFD) Tools for Investigating Flow and Mixing in Industrial Systems: The Koch-Glitsch SMX Static Mixer and a Three Rushton Turbine Stirred Tank. New Brunswick, NJ: Department of Chemical & Biochemical Engineering, Rutgers University; 2000.

Zalc JM, Alvarez MM, Muzzio FJ. Extensive validation of computed laminar flow in a stirred tank with three Rushton turbines.AIChE J. 2001;47:2144–2154.

Mauger JW, Brockson R, De S, Gray VA, Robinson D. Intrinsic dissolution performance ofUSP Apparatus 2 using modified salicylic acid calibrator tablets: proof of principle.Diss Tech. 2003;10:6–15.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: January 3, 2006

Rights and permissions

About this article

Cite this article

Baxter, J.L., Kukura, J. & Muzzio, F.J. Shear-induced variability in the United States pharmacopeia apparatus 2: Modifications to the existing system. AAPS J 7, 83 (2005). https://doi.org/10.1208/aapsj070483

Received:

Accepted:

DOI: https://doi.org/10.1208/aapsj070483