ABSTRACT

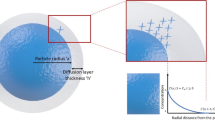

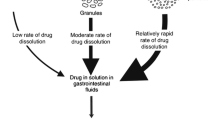

An ultrasound-assisted powder-coating technique was used to produce a homogeneous powder formulation of a low-dose active pharmaceutical ingredient (API). The powdered particles of microcrystalline cellulose (MCC; Avicel® PH-200) were coated with a 4% m/V aqueous solution of riboflavin sodium phosphate, producing a uniform drug layer on the particle surfaces. It was possible to regulate the amount of API in the treated powder. The thickness of the API layer on the surface of the MCC particles increased near linearly as the number of coating cycles increased, allowing a precise control of the drug content. The tablets (n = 950) prepared from the coated powder showed significantly improved weight and content uniformity in comparison with the reference tablets compressed from a physical binary powder mixture. This was due to the coated formulation remaining uniform during the entire tabletting process, whereas the physical mixture of the powders was subject to segregation. In conclusion, the ultrasound-assisted technique presented here is an effective tool for homogeneous drug coating of powders of irregular particle shape and broad particle size distribution, improving content uniformity of low-dose API in tablets, and consequently, ensuring the safe delivery of a potent active substance to patients.

Similar content being viewed by others

REFERENCES

Jivraj M, Martini LG, Thomson CM. An overview of the different excipients useful for the direct compression of tablets. Pharm Sci Technol Today. 2000;3:58–63.

Prescott JK, Hossfeld RJ. Maintaining product uniformity and uninterrupted flow to direct compression tablet presses. Pharm Technol. 1994;18:99–114.

Bolhuis GK, Chowhan ZT. Materials for direct compression. In: Alderborn G, Nysröm C, editors. Pharmaceutical Powder Compaction Technology. New York: Marcel Dekker; 1996. p. 420–500.

Thiel WJ, Nguyen LT, Sberna FJ. Content uniformity of microdose tablets (dosage 1 microgram10 mg) produced by fluid bed granulation of interactive mixtures. J Pharm Pharmacol. 1986;38:335–43.

de Haan P, Thys CP, inventors. Compressed dry-granulation desogestrel tablets. United States patent US 6063403. 1997 Dec 18.

Greaves FC, Beasley MW, Suddith AW, Swarbrick J. Novel approaches to the preparation of low-dose solid dosage forms. Pharm Technol. 1995;188:60–4.

Parikh DM. Introduction. In: Parikh DM, editor. Handbook of Pharmaceutical Granulation Technology. New York: Marcel Dekker; 1997. p. 1–5.

am Ende MT, Moses SK, Carella AJ, Gadkari RA, Graul TW, Otano AL, et al. Improving the content uniformity of a low-dose tablet formulation through roller compaction optimization. Pharm Dev Technol. 2007;12:391–404. doi:10.1080/10837450701369253.

Wu L-S, Pang J, Chen J-G, Hussain MA. Dry blending process scale-up for a very low dose drug candidate. AAPS PharmSciTech. 2000;1:article TN2.

de Haan P, Deurloo M, inventors. Low steroid dose dry pharmaceutical preparation. United States patent US 5382434. 1995 Jan 17.

Lerner LJ, inventor. Modified sequential oral contraceptive. United States patent US 3568828. 1971 Mar 9.

Grawe D, Hoesel P, Moellmann P, Timpe C, Dittgen M, Matthey K, inventors. Homogeneous preformulations containing high concentrations of steroids, for producing low-dose solid and semi-solid pharmaceutical preparations. United States patent US 6290931B1. 2001 Sep 18.

Rowe RC, Sheskey PJ, Quinn ME, editors. Handbook of Pharmaceutical Excipients. 6th ed. London: Pharmaceutical Press; 2009.

Genina N, Räikkönen H, Heinämäki J, Antikainen O, Siiriä S, Veski P, et al. Effective modification of particle surface properties using ultrasonic water mist. AAPS PharmSciTech. 2009;10:282–8. doi:10.1208/s12249-009-9208-3.

Bodson C, Dewé W, Hubert Ph, Delattre L. Comparison of FT-NIR transmission and UV-vis spectrophotometry to follow the mixing kinetics and to assay low-dose tablets containing riboflavin. J Pharm Biomed Anal. 2006;41:783–90. doi:10.1016/j.jpba.2006.01.022.

Guo HX, Heinämäki J, Yliruusi J. Characterization of particle deformation during compression measured by confocal laser scanning microscopy. Int J Pharm. 1999;186:99–108.

ACKNOWLEDGEMENTS

The Estonian National Scholarship Fund is acknowledged for financial support. Juha Hatara is thanked for helping with the acquisition of the digital images. Student Andrea Lanzetti is acknowledged for technical assistance with the tablet analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Genina, N., Räikkönen, H., Antikainen, O. et al. Ultrasound-assisted powder-coating technique to improve content uniformity of low-dose solid dosage forms. AAPS PharmSciTech 11, 1320–1327 (2010). https://doi.org/10.1208/s12249-010-9514-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-010-9514-9