Abstract

This study presents archaeometric analyses of glazed tiles produced with the cut-mosaic technique to reveal information about the Anatolian Seljuk period’s architecture and ceramic technology. The Persian Seljuk artists also used the same technique. For this purpose, physical, chemical, thermal, mineralogical, microstructural, and molecular analyses were carried out on the tiles from the Seljuk period unearthed in the Kılıçarslan Square excavation in Konya, the capital of the Anatolian Seljuk State from the twelfth-century to the beginning of the fourteenth-century. SEM, XRD, and Heat Microscopy analyses showed that the Seljuk period tiles were not fired at high temperatures like today’s tiles and were probably fired at temperatures below 1100 °C. WD-XRF analyses revealed that the glazes are classified into two categories, one being alkali varying the content of Na2O + K2O between 13 and 16 wt% (PbO between 0.5 and 2 wt%) and the other being lead-alkali type in which PbO content varies between 13 and 15 wt% and alkali content 10–14 wt%. The cobalt content in the blue color is around 0.2 wt%, and copper content in the turquoise-colored samples varies between 2.9 and 4.4 wt% depending on the lightness and darkness of the color (higher amount for tile 1 and tile 3, which are darker than the others). The brown color is obtained by the presence of MnO (3.3 wt%). Raman analysis showed that the difference in sintering temperature caused the color tone difference in Seljuk period tiles, and glazes were formed in the range of 800–1000 °C depending on the Ip values.

Similar content being viewed by others

Introduction

A new approach to determining the characteristics of archaeological artifacts, which has become increasingly widespread in Turkey after the 1990s, uses the archaeometric method [1,2,3,4,5]. With the archaeometric approach, much information can be obtained, such as production technology and the date of manufacture, their originality, restoration date, and atmospheric effects that the material has been exposed to over time. In addition, with the data obtained by these methods, historical buildings can be restored by staying true to the original [6,7,8,9].

Konya, the capital of the Anatolian Seljuk State (twelfth-early fourteenth-centuries), is rich in archaeological terms. The Alâeddin Mosque, Sırçalı Madrasa, Karatay Madrasa, İnce Minareli Madrasa, Beyşehir Eşrefoğlu Mosque, Kılıçaslan Pavilion, and Kubad Abad Palace are among the essential historical buildings of the Anatolian Seljuk period built in Konya [10, 11]. During the archaeological excavations in Konya, many remaining ceramic, glass, and metal artifacts were unearthed [11,12,13,14,15,16]. One of the types of these artifacts found in the archaeological excavations is the tiles, which are the characteristic wall revetments and covering materials of the Anatolian Seljuk architecture [10, 11]. The tiles used in religious architecture are produced by the cut-mosaic technique, where geometric and floral motifs are drawn. However, in civil architecture, burnished tiles predominate the walls of the buildings. Moreover, various human, animal, and mythical figures are seen as well as geometric and floral motifs [17]. In the cut-mosaic technique, the tiled panels are formed by bringing together the tile pieces cut according to the desired decor from the plate tiles produced in different colors on a plaster ground to form a composition. This ornamentation of the tiles spread in Central Asia from the end of the forteenth-century to the Ottoman Empire during the fifteenth- and sixteenth-centuries and finally in Iran and India during the Safavid reign [18]. A previous study was carried out about the characterization of the building tiles of the ancient monuments of the thirteenth-century Seljuk period, namely Sivas Gök Madrasa and Tokat Gök Madrasa, with XRD and Raman micro-spectrometry [19].

Moreover, a similar study was performed on the Iranian monochrome glazed mosaic tiles produced with the same technique (cut-mosaic) [20]. According to the findings obtained from the evaluations made by art historians or social scientists about Anatolian Seljuk period tiles, the tiles used in the cut-mosaic technique have a porous and loose body and a thinner glaze layer compared to the standard tiles. In this technique, the glaze thickness is lower, so the fired tile sheet can be easily processed as desired by scraping with a cutting tool. Therefore, it is possible to cover concave curved surfaces such as arches and vaults with tiles enriched with geometric and floral motifs [11]. The colors known at that time in the architecture of the Anatolian Seljuk period and used in the cut-mosaic technique are turquoise, cobalt, black, green, and violet-brown [21].

Anatolian Seljuk tile technology, which also forms the basis of Ottoman tile making, is an important subject for thirteenth–fourteenth-century Turkish-Islamic ceramic research, but not much research has been done on the archaeometric methods by scientists. However, a few recent archaeometric studies on the Seljuk period have shown that the bodies of the tiles were made of quartz, frit, and plastic clay [11, 22]. The amount of quartz used in the body composition is high, around 85–90 wt%. Clays with high binding properties were preferred to provide plasticity and mechanical bonding to the substrate. The frit used in the composition is usually lime-alkali and lead-free. No slip layer was used on these tiles. The glazes of the Seljuk period wall tiles are divided into two categories, rich in soda or lead-alkali [19].

Furthermore, the glaze surfaces are either transparent or opaque. Soda-lime and alkali fluxes are preferred for transparent glazes, while tin oxide and lead-alkali fluxes are preferred for opaque ones. Besides, it is also reported that Anatolian Seljuk period tiles were fired at around 900 °C [11, 23,24,25,26].

Literature research has shown that the Anatolian Seljuk period artifacts examined by archaeometric methods are the artifacts found in Sivas, Tokat, Malatya, Beyşehir (Kubad Abad Palace), and Alanya [23,24,25,26,27,28,29,30]. However, it has been determined that a comprehensive archaeometric study has not been carried out on the artifacts belonging to the Seljuk period in the center of Konya [23, 24, 30, 31].

In this study, the Seljuk period tile fragments, obtained from the Konya Museum Directorate, were unearthed in the excavation of Kılıçarslan Square between 2012 and 2017. In this square, Karatay Madrasa, inscribed in 1251, has among the first tile works of Konya (the location of Konya in Turkey is shown in Fig. 1), the capital of the Anatolian Seljuk State, was characterized by the archaeometric methods. Therefore, the study can have the potential to provide important clues about Konya tiling in the Anatolian Seljuk period.

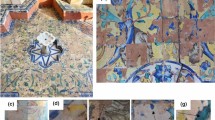

top left Map of Turkey dated to the fourteenth century showing Konya in the red circle [32], bottom and right View of tile panels produced by cut-mosaic technique preserved in the Karatay Madrasa (Konya, Turkey) (photos: Çetin Öztürk)

Within the scope of the characterization studies, physical, chemical, mineralogical, molecular, microstructural, and thermal analyses were carried out on the glazed tile from the Konya Seljuk period, and these were aimed at obtaining information about the origin of the raw materials, tile production techniques, firing temperatures, and pigments used. Furthermore, the data obtained with the archaeometric techniques used in this study are essential for the periodical classification of the glazed tiles produced in different periods and for restoring the original tiles. This paper presents the archaeometric studies according to the characterization technique used. It starts to present the glazes first and then the bodies because the production technology may categorize them properly concerning the composition of the glazes, being alkali or lead-alkali.

Materials and methods

The surfaces of six tile sherds obtained from the Konya Museum were washed with deionized water and cleaned with the help of a soft brush. Before the characterization studies, the sherds were classified visually and digitally with a handheld Munsell gun (Pantone Capsure), numbered from 1 to 6 (see Table 1), and photographed (Fig. 2). Unfortunately, ethical rules in Turkey now limit the destructive analyses of cultural heritage artifacts as much as possible. Therefore a limited number of samples representative of different colors (dark blue, turquoise, dark turquoise, and violet brown) were chosen for this study. The hue differences of the turquoise tiles may be seen in the tile panels shown in Fig. 1 right.

Before the characterization studies, the cross-sections were examined with a stereo microscope (Leica s9i) at 20–40× magnifications (Fig. 3). A visual assessment revealed that five tiles have a porous texture and could be crumbled by hand. Only the body of tile 4 is denser, and the grains are finer than other tiles. In addition to the texture, tile 4 has a reddish-colored body, the others have whitish tones, and all tiles have no slip layer.

Using scanning electron microscopy (SEM, Leo 1430 VP, Germany), the microstructure of tiles was examined in terms of formed phases, porosity, glaze layers, etc. The size of the glaze layers, grains, and pores were manually measured using the scale bar (yellow) on the SEM micrographs. For these measurements, at least five measurements were made on the mentioned microstructure component from each sample, and the average values of these measurements were calculated. The chemical composition of the body, glaze, and coloring agents were determined by the WD-XRF instrument. The composition of glazes were measured from the top surface and the body compositions from the powdered samples after grinding with a pestle. The analyses were carried out with a BRUKER S8 Tiger WD-XRF instrument working with a 4 kW rhodium anode under vacuum for glaze and helium atmosphere for the powdered body. The measurements were performed at 50 kV and 60 mA. The analysis mode, “Best Detection”, which lasts for 18 min, was chosen. A macro measurement was performed on the samples rather than a spot analysis because of the larger aperture size (0.5 cm). The data is evaluated ' 'using the Bruker's Spectra Plus Eval2 V2.2.485. The crystal structure of tile bodies was characterized with an X-ray diffractometer (XRD; Bruker-D8 Advance) using Cu-Kα radiation (λ = 1.5406 Å) scanning from 5° to 90° at a rate of 2°/min, and the divergence and scattering slit widths were set at 1 mm. The analysis depth for XRD was 5–7 µm, and the analysis area was 0.5 × 0.5 cm2.

A completely automated Renishaw inVia confocal Raman microscope was used with a 532 nm (green) laser excitation to define the glaze signature, which is the fingerprint of each tile. The exit power of the laser is 100 mW and 60 mW on the sample without any objective. A Leica long working distance objective with 50× magnification (N Plan, NA 0.50) was used at 1, and 10% decreased power. 100% laser power was measured at 9.29 mW at the exit of the objective and 0.153 mW at 1% power. The recording time of the spectrum ranged between 10 and 60 s. Approximately 2 × 2 µm2 of the area is scanned with the instrument. The data are kept with the original software of the instrument, WIRE version 4.4, and post-processed with the LabSpec software (version 5.25.15) to perform baseline subtraction which allows the investigation of the bending and stretching envelopes. The index of polymerization is calculated from the ratio of bending to stretching areas of the molecular Si–O Raman signature with the software Origin 6.0 Peak Fitting by using the peak function of Gaussian. The sintering behavior of tile samples was evaluated by a heating microscope (Misura HSM 3 M Italy) according to the DIN 51730 standard. The tiles were heated up to 1300 °C with a heating rate of 25 °C min−1.

Results and discussion

Microstructural investigations

Microscopic examination of the cross-sections of the tiles, which show the glaze and body layers, were carried out with SEM and micrographs of observed cross-sections are presented in Fig. 4.

In the SEM micrographs of the tile samples (Fig. 4), it was observed that the glaze layer has a contrast that can be easily distinguished from the body in the microstructure of tiles 2, 3, and 6. In these samples, it can be clearly understood that the glaze layer is more glassy in structure, according to the body on which it is applied and compared to other tile samples. The chemical composition difference between the body and the glaze layer and the vitrification degree of the glaze layer may be evaluated as the factors that may cause this contrast difference. In the micrographs of tiles 1, 4, and 5, a distinguishable contrast difference between the glaze layer and the body was not observed. This lack of contrast was evaluated such that the lack of contrast difference might be due to the lower vitrification degree of the glaze layers in these samples compared to the others.

SEM images of investigated glazed tiles cross-sections revealed that the average thicknesses of the glazes vary between 364 and 583 μm (Table 1). The highest and lowest glaze thickness was observed in tile 6 and tile 1, respectively. On the other hand, the presence of crystalline phases and bubble formation was not observed in the cross-sectional images of all glaze layers examined. Formation of the melt and dissolution of the hard raw materials is essential to obtain a smooth and relatively bubble-free glaze. In order to dissolve hard raw materials (e.g., quartz) in the melt, either high firing temperatures are required, or the use of a certain significant amount of pre-melted glass (frit) or fluxes in the glaze composition is required [33, 34]. The following sections discuss the absence of crystal phase and bubble formation in the glaze cross-sections in detail regarding chemical composition and firing temperature.

Figure 5 presents images taken at different magnifications in secondary electron mode (SEI) in scanning electron microscopy on tile bodies. Due to the differences in the cross-sectional areas of the samples, images representing the general microstructure were taken at 500× magnification for tiles 1, 2, and 5, and 1000× magnification for tiles 3, 4, and 6, respectively. From the micrographs presented in Fig. 5, it can be understood that the general microstructure for all samples consists of a matrix structure, angular quartz crystals with different grain sizes, which preserved the original crystal morphology embedded in the matrix structure, and pores of different sizes and angular geometries. Comparing micrographs, it can be observed that quartz particle size caused differences in the microstructure development of the tiles. For example, it is noteworthy that the 1st tile is denser, and the 4th tile is more porous than the others. As seen in Table 1, where the particle size measurement results performed in SEM micrographs are presented, the quartz particles in tiles 2, 4, and 5 were more coarse than the other series. In this series, the sintered bodies with coarse quartz particle sizes (Fig. 5b, d, e) show a rough and granular texture.

Moreover, in these tiles, pores around large quartz grains are visible. The presence of large pores around the quartz grains embedded in the matrix structure may be due to coarse quartz particles forming a heterogeneous structure in the matrix and the lack of sufficient liquid phase to fill the pores. This also indicates that the quartz particles are unmelted due to the lack of liquid phase. The irregular shape of the pores and the presence of sharp-edged quartz grains are characteristics of low-grade liquid-phase sintering [35, 36]. This is because the liquid phase suppresses the small pores and facilitates quartz dissolution, rounding quartz particle edges and reducing the number of small pores. Considering that quartz particles are easily dissolved in the liquid phase in bodies fired to ~ 1210 °C [37] and higher, it can be understood that the firing temperature of tiles 2, 4, and 5 was lower than 1200 °C.

On the contrary, tiles 1, 3, and 6 were evaluated as having a more compact and homogeneous microstructure. Assuming that these samples were fired under the same conditions as the others, it can be thought that the chemical composition (type and amount of fluxes) plays an influential role in this difference. Consequently, in tiles 2, 4, and 5, due to low sintering, both the absence of a glassy phase in which coarse quartz particles will dissolve and the formation of pores of 5–20 µm by these coarse particles delayed the microstructure homogenization.

Considering that the microstructures of tile samples are compared with today's traditional tile body microstructures, the most crucial difference is the absence of a glassy phase and coarse quartz grains. This is because, when producing today's tiles, the starting raw materials are generally ground to a fineness of less than 63 µm, and the particle sizes are further reduced by the partial dissolution of the hard raw materials in the glassy phase developed during the firing stage [38]. Large quartz grains in the Seljuk period tile bodies indicate that this behavior did not occur. It is understood that the tiles of the Seljuk period were fired at lower temperatures than today's tiles (1100–1200 °C) [37], since the liquid phase required for the dissolution of the quartz grains did not occur.

Chemical analysis of tiles

Chemical analysis of glazes

WD-XRF analysis results performed on the glaze layers of the tile samples revealed that the amount of SiO2 varies between 45.5 and 67.3 wt% and the amount of Al2O3 varies between 4.2 and 6.6 wt% (Table 2). It was determined that the total alkaline composition (Na2O + K2O) of the glaze layers of the tile samples varied between 9.7 and 15.9 wt%. The PbO content of the glazes was between 0.5 and 2.2 wt%, except for the tile samples 3 (15.1 wt%) and 5 (12.7 wt%). With these findings, it is possible to divide the glaze compositions of the examined tiles into two categories: (a) Lead-alkali glazes containing a moderate amount of lead (tiles 3 and 5), and (b) alkali glazes (tiles 1, 2, 4, and 6). When evaluated according to CaO, another fluxing oxide other than lead and alkali: CaO content was found to be high (> 6%) in tiles 1, 4, and 5, and low values in other series.

WD-XRF measurements showed that the glaze of tiles 3 and 5 have alkaline rich lead-alkaline type glaze. The high content of sulfur in tile 5, both in the body and glaze layer, may imply to the use of galena (PbS). A previous study about the earlier periods of Islamic ceramics detected the presence of PbS precipitates relating to some processing of galena lead ore (PbS). The formation may be due to the process of oxidation of galena to obtain lead oxide [39]. In addition, SnO2 (cassiterite) was detected only in tile 3 (4.93 wt%) and tile 5 (7.66 wt%). SnO2, which is part in opacifying the glaze, was used extensively in Seljuk period tiles [40]. The evaluation made according to the Sn/Pb ratio in the glaze layer is a practical approach to determining and classifying the period of the artifacts examined [41, 42]. Periodical classification of artifacts according to the Sn/Pb ratios in the glaze, which reference data obtained from the literature [41, 42], is shown in Fig. 6. As the Sn/Pb ratio of tiles from different periods is compared (Fig. 6), it can be seen that the Sn/Pb ratio in tiles from the Seljuk period is between 0.2 and 0.3. The Sn/Pb ratios of tiles 3 and 5 are 0.33 (4.93/15.1) and 0.60 (7.66/12.7), respectively. Compared to the literature (Fig. 6), the values are high, and tile 5 is similar to the Timurids period in this respect. Sn was not detected in tiles 1, 2, and 6, and contain less Pb in the glaze composition and can be classified under Iznik 17th—according to Fig. 6. Also, tile 4 can be classified under Iznik 17th—due to low Sn/Pb ratio.

CuO, which gives the turquoise color and its shades to the glazes of Seljuk tiles, was detected in the range of 2.93–4.42 wt% in tiles 1, 3, 4, and 5. These results are compatible with the study [23] on the Seljuk period tiles in the literature. In tile 6, the violet-brown color was due to the content of MnO (3.31 wt%) in the glaze composition. These results are also compatible with the studies [28, 41] on the Seljuk period tiles in the literature. The dark blue color of tile 2 derives from the content of cobalt (CoO, 0.17 wt%) with a high amount of Fe (Fe2O3: 5.2 wt%) and a low amount of Mn (MnO, 0.007 wt%) and Cu (CuO: 0.28 wt%) color.

Chemical analysis of tile bodies

The composition of the body layers was measured with WD-XRF, and the obtained values are presented in Table 2.

From the chemical analyses of the body layers shown in Table 2, it can be understood that all tiles consist of a high amount of silica (> 83 wt% SiO2). It has been determined that the amount of SiO2 in the tiles varies between 84 and 91 wt%, and the lowest SiO2 amount is in tile 1, and the highest SiO2 content is in tile 4. The amount of Al2O3 in the tiles varies between 4.20 and 9.16 wt%. It has been determined that the lowest Al2O3 content is in tile 4, and the highest Al2O3 content is in tile 1, contrary to the situation in SiO2. Freestone et al. [30] study on the tile bodies found in the Kubad Abad palace, a Seljuk period structure placed in the Konya Beyşehir district, stated that the Al2O3 content is around 6 wt%. The high Al2O3 content compared to the Iranian tile bodies of the same period is a characteristic feature of the Anatolian Seljuk tile bodies [30]. Besides the Kubad Abad study, the data obtained from Tiles 1–6 was also compared to the previous studies carried out on fifteenth-century productions of Mescid-i Kabud (Tabriz), sixteenth-century Caravanserai (East Azerbaijan), and earlier productions of Iznik tiles (fourteenth–fifteenth centuries). These tiles also have monochrome glazes in different colors, turquoise, cobalt, dark green, and black. The scattering plot of Al2O3 versus SiO2 in Fig. 7 demonstrates the differentiation of different production centers for similar tiles. This plot summarizes that the tiles investigated in this study have a higher amount of alumina and quartz.

The amount of Fe2O3 + TiO2, which determines the color of the body, is in the range of 0.99–1.93 wt%. The body colors of tiles 4 and 6 with high Fe2O3 content are slightly reddish, as expected.

When compared in terms of Fe2O3 amount, it can be seen that Kılıçarslan bodies have higher values than Kubad Abad bodies (Kubad Abad bodies having a Fe2O3 average of 0.49 wt%) [22]. Fe2O3 and Al2O3, which are thought to come from the clay, do not increase in proportion to each other, suggesting that a different type of clay may have been used in the recipe. Freestone et al. [30] suggest that using kaolinite-type clay could have achieved the high Al2O3 content and beige firing color for Anatolian Seljuk tiles.

When the alkali ratios of the bodies are analyzed, it can be seen that Na2O range between 1.22 and 1.69 wt% and K2O ranges between 0.44 and 0.94 wt%. The bodies’ total alkali ratio (Na2O + K2O) is between 1.82 and 2.6 wt%. Alkali ratio affects vitrification during firing, interconnection of quartz particles, and firing strength. Freestone et al. [26] state that the soda content of Kubad Abad tile bodies is lower (1.2 wt% Na2O on average) than Syrian, Egyptian, and Iranian high silica bodies. This value is consistent with similar studies conducted in this field [22, 29, 30]. It was reported that plant ashes such as Salsola or Salicornia, which grow on lakesides, were used as alkali sources in Seljuk tile making [11, 22, 43,44,45]. Lead is present in trace amounts as an impurity in the tile bodies.

Şerare Yetkin states that Seljuk tiles contain 2–5 wt.% of lime [11]. WD-XRF analysis resulted in a high CaO ratio in the bodies (< 3.6 wt%), indicating that some lime was added to the recipe or a calcareous clay was used. The reason for adding lime is to enhance plasticity and binding properties to the mass and dry strength before firing [46, 47].

Raman analysis of glazes

Glazes are glassy silicates in which the oxygen atoms at the vertices join the SiO4 tetrahedra together. These tetrahedral connections can be affected and modified by other ions like aluminum (Al), magnesium (Mg), iron (Fe), etc., and alkali/alkaline earth metal ions, which change the physical and chemical properties of the glass structure. The intensity change can observe these modifications changing the intensity, band positions, and width [48, 49]. The SiO4 tetrahedra have a well-defined vibrational signature, especially in Raman scattering [50,51,52,53,54,55]. The spectrum consists of a band at ~ 500 cm−1 (Si–O bending mode) and the other band at ~ 1000 cm−1 (Si–O stretching mode). The glaze spectra can also exhibit narrow Raman peaks due to the pigments and crystalline precipitates in the glaze structure [51].

Figure 8 shows the glaze signature of the tile sherds determined with the confocal Raman spectrometer. The maximum wavenumber of the stretching band varies between 1050 and 1094 cm−1, while the maximum bending massif area is between 474 and 571 cm−1. A previous study carried out on Topkapi Palace Museum tiles [56] showed that in the presence of alkali-rich glaze, the bending bands are wide and shift from lower (around 450 cm−1) to higher wavenumbers (535–580 cm−1). In the case of lead-alkali type glaze, as encountered in tiles 3 and 5, the Raman stretching massif has a doublet band having Q2 (located at around 980 cm−1) and Q3 components (located at around 1050–1060 cm−1). The representative peaks of cassiterite (SnO2) found as a crystalline precipitate in the glaze is evident in the Raman spectrum of tile 5 at 633 and 778 cm−1.

The ratio of areas under the Raman band of bending and stretching envelopes, A500/A1000 is defined as Ip, which is the polymerization index already described in a previous study [48]. It is affected by the glass composition and process temperature. Regarding the values obtained, the glazing structure can be classified as [51, 57];

-

(a)

Ip < 0.3–0.5, corresponding to lead-rich silicates processed at low T (< 700 °C)

-

(b)

0.5 < Ip < 0.8, corresponding to lead-based silicates processed at medium T (~ 800 °C)

-

(c)

0.8 < Ip < 1.1, corresponding to most ancient alkaline glasses and enamels (T ~ 1000 °C)

-

(d)

1.1 < Ip < 1.3, corresponding to mixed sodium-calcium based glassy silicates (T ~ 1100 °C)

-

(e)

1.3 < Ip < 2.5, corresponding to calcium-based glassy silicates (T ~ 1200 °C)

-

(f)

2.5 < Ip, Aluminum containing corresponding to potassium-based glazes (T ~ 1300 °C)

Figure 9a shows the range of Ip values which varies between 0.77 and 0.92 by confirming the presence of an alkaline composition fired at a lower temperature than 1100 °C. Due to the non-uniformity of the glaze thicknesses, the ratio of the bending and stretching areas is not directly correlated to the composition of the glaze. However, the ratio of the intensities of stretching and bending spectral components revealed a comparable correlation between lead oxide (PbO) content in the glaze and Raman intensities. The disorder of the data may be derived from the heterogeneous structure of the glaze layer. The ratio of the Raman intensities (RI), RI500 versus RI1000, decreases when the glaze's lead content decreases (Fig. 9b).

Mineralogical analysis of tiles

Besides the elemental composition of bodies obtained by WD-XRF, the crystalline phases formed after firing the bodies are determined by XRD analysis. XRD patterns of the investigated bodies from the Kılıçarslan Square Excavation are presented in Fig. 10.

XRD patterns of the tile bodies (Fig. 10) showed that the dominant phase is quartz, as predicted from the chemical analysis results, which refer to the presence of a stone paste body. Magnesium–aluminium–silicate, anorthoclase, sodium–aluminium silicate, and calcite phases are the other phases encountered in the tile bodies. The fact that the quartz phase is the dominant phase in the microstructure is due to the high use of silica in the production of Seljuk tile bodies, as mentioned in Ebu'l Kasım's book dated 1301 [22]. Even the determined crystalline phases do not vary between investigated tiles; diffraction degrees and intensities of quartz phases (Fig. 10 vary due to different quartz grain fractions and sizes in tile bodies. No mullite phase (3Al2O3.2SiO2) formation is observed in the patterns, suggesting that the firing temperature of the bodies is below 1100 °C. Raman analysis of the glazes also supports this finding which indicates that glazes are formed between 800 and 1000 °C. Besides this finding, when the tiles are examined on a macro scale, they can be easily crumbled by hand, and, on the other hand, examined on a micro scale, the vibration and hump-shaped curves that characterize the amorphous phase were not observed in the XRD patterns, which indicates that the examined tiles were fired at temperatures lower than 1100 °C which supports the Raman analysis. When the findings obtained as a result of XRD are discussed based on the literature, it is consistent with the outcome of firing the Seljuk period tiles below 900 °C, as stated by the researchers in previous studies on the same subject [10, 27,28,29,30, 44].

Sintering behavior by heating microscopy analysis

Figure 11 and Table 3 show a minor swelling between 0.35 and 1% in all tile samples at 800 °C. It can be said that the small size variations observed at temperatures between 800 and 1000 °C are due to the decomposition of clay minerals [58]. The sintering point is considered the temperature point at which shrinkage starts and continues to increase at the initial size of the sample taken as 100% [59, 60]. Table 3 shows that shrinkage starts at 1000 °C for Tiles 1, 3, and 6, at 1050 °C for Tiles 4 and 5, and at 1150 °C for Tile 2, and shrinkage continues as the temperature increases. The shrinkage percent versus temperature plot in Fig. 11 reveals that sintering points are between 972 and 1117 °C for all the tiles.

It is known that the sintering mechanism in silicate ceramics is mostly liquid phase sintering. With liquid phase sintering, the pores in the body are filled with viscous melt, which makes the body more durable than the porous state [61]. However, it can be said that the sintering mechanism is solid state sintering rather than a liquid phase, as the bodies fired at low temperatures do not form enough viscous liquid phase during firing (causing the formation of brittle bodies). The low sintering degree obtained after the low-temperature firing process in the solid state sintering mechanism is generally evaluated negatively regarding the final product properties. However, in cases where easy-to-process material production is desired, as in the cut mosaic tile technique, firing conditions where a solid-state sintering mechanism will be valid and a low sintering degree will be obtained as desired in a targeted manner. Although the sintering beginning temperature of the tile samples was between 972 and 1117 °C, the fact that the presence of a liquid phase in the microstructure could not be detected, and the samples in question were easily processed by hand; it is thought that these samples were fired at low temperatures (< 972 °C).

Conclusions

Six glazed tile sherds unearthed from the Konya Kılıçarslan Square excavation dated to Anatolian Seljuk Period were characterized by archaeometric methods. According to visual assessment, the bodies of all tiles have a porous texture and may be crumbled by hand.

The presence of crystalline phases and bubble formation was not observed in the cross-sectional images of all glaze layers. This situation drew attention to the fact that the tiles were either fired at high temperatures or a significant amount of frit or fluxes (alkali or lead) was included in the glaze composition to dissolve the hard raw materials (e.g., quartz). The results of SEM, XRD, Raman, and Heat microscope analysis confirmed that the tiles were not fired at high temperatures (> 1100 °C). The chemical analysis results confirmed that the glaze compositions of the tiles contained significant amounts of alkali and calcium. WD-XRF analyses performed on the glaze layer of the tiles revealed that the type of the glazes is alkali and alkali-rich lead-alkali glazes.

SEM analysis indicated that the general microstructure for all tile bodies consisted of a matrix structure, angular quartz crystals with different grain sizes, which retained the original crystal morphology embedded in the matrix structure, and pores with different sizes and angular geometries. The presence of large pores around the quartz grains embedded in the matrix structure was evaluated as resulting from a sufficient liquid phase that did not develop during the firing stage so that the coarse quartz grains could dissolve and fill the pores around it. Considering that quartz particles dissolve easily in the liquid phase in bodies fired at 1200 °C and higher, it is understood that the firing temperature of the tiles examined was below 1200 °C. The data obtained from SEM, XRD, Raman, and heat microscopy measurements confirmed that the tiles were fired at temperatures lower than 1100 °C.

Raman measurements showed that Tiles 1 and 4 have the same glaze structure, confirmed by the chemical analyses with WD-XRF. The color difference (darker turquoise for tile 1 and lighter for tile 4) has arisen from the difference in the sintering temperature. For tiles 3 and 5, the maximum point of the stretching band is lower than the other turquoise-colored tiles, 1065 and 1050 cm−1, respectively. Because SiO2 content is higher in the glazes of tiles 2 (65.2 wt%) and 6 (67.3 wt%), the bending maxima are located at lower wavenumbers, 474 and 518 cm−1, respectively. Ip values indicate that the glazes were formed in the 800–1000 °C range.

The chemical analysis of bodies indicated that all tiles consist of high silica (> 83 wt% SiO2). XRD patterns of tile bodies showed that the dominant phase is quartz. Magnesium–aluminium–silicate, anorthoclase, sodium–aluminium silicate, and calcite phases are the other phases encountered in the bodies.

This study may contribute to the restoration works on the Seljukian period productions and will shed light on further investigations for the classification of the glazed ceramics of the Seljuk period depending on the raw materials, workshops, and production periods.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffractometer

- WD-XRF:

-

Wavelength dispersive X-ray fluorescence spectrometer

- Q:

-

Quartz

- P:

-

Pore

- N.D.:

-

Not detected

- RI:

-

Raman intensities

References

Bayazit M, Işık I, İssi A, Genç E. Archaeometric investigation of the Late Chalcolithic-Early Bronze Age I and the 1st–2nd millennium BCE potteries from Kuriki-Turkey. Appl Clay Sci. 2016;126:180–9. https://doi.org/10.1016/j.clay.2016.03.013.

Gutsuz P, Kibaroğlu M, Sunal G, Hacıosmanoğlu S. Geochemical characterization of clay deposits in the Amuq Valley (Southern Turkey) and the implications for archaeometric study of ancient ceramics. Appl Clay Sci. 2017;141:316–33. https://doi.org/10.1016/j.clay.2017.03.004.

Bigazzi G, Ercan T, Oddone M, Özdoğan M, Yeğingil Z. Application of fission track dating to archaeometry: provenance studies of prehistoric obsidian artifacts. Nucl Tracks Radiat Meas. 1993;22(1–4):757–62. https://doi.org/10.1016/0969-8078(93)90172-Z.

Tarhan İ, Işık İ. An in-depth chemometric study: archaeometric characterization of ceramic shards excavated from the sanctuary of Hecate at Lagina in Muğla (Turkey) by FTIR spectroscopy and multivariate data analysis. Vib Spectrosc. 2020;111:1–11. https://doi.org/10.1016/j.vibspec.2020.103172.

Özkul Fındık N, Akyol AA, Sarı N. Archaeometric analyses of Hasankeyf unglazed ceramics. Mediter Archaeol Archaeom. 2014;14(1):261–71.

Tite MS. Ceramic production, provenance and use—a review. Archaeometry. 2008;50(2):216–31. https://doi.org/10.1111/j.1475-4754.2008.00391.x.

Mason RB, Tite MS. The beginnings of Islamic stonepaste technology. Archaeometry. 1994;36(1):77–91. https://doi.org/10.1111/j.1475-4754.1994.tb01066.x.

Liritzis I, Laskaris N, Vafiadou A, Karapanagiotis I, Volonakis P, Papageorgopoulou C, Bratitsi M. Archaeometry: an overview. Sci Cult. 2020;6(1):49–98. https://doi.org/10.5281/zenodo.3625220.

Özçatal M, Yaygıngöl M, İssi A, Kara A, Turan S, Okyar F, Pfeiffer Taşc Ş, Nastovad I, Grupčed O, Minčeva-Šukarovad B. Characterization of lead glazed potteries from Smyrna (İzmir/Turkey) using multiple analytical techniques. Part II: body. Ceram Int. 2014;40(1):2143–51. https://doi.org/10.1016/j.ceramint.2013.07.132.

Topaksu M, Yeğingil Z, Sakarya, N, Arık R, Ukav İ. Kubad Abad Seramik ve Çinilerinin Analiz Sonuçları. 19.Arkeometri Sonuçları Toplantısı, Kültür ve Turizm Bakanlığı Yayınları, No:96. Ankara. 2003; p. 73–84.

Yetkin Ş. Anadolu ‘da Türk Çini Sanatının Gelişmesi. İstanbul Üniversitesi Edebiyat Fakültesi Yayınları No: 1631, İstanbul. 1972; p.153–159.

Aygör E. Konya Gevale Kalesi kazılarında bulunan ok uçlarının değerlendirilmesi. MASROP E-Dergi. 2017;11(1):7–24.

Çaycı A, Şimşir Z. Gevale Kalesi 2013–2014 Kazı Buluntuları. 37. Uluslararası Kazı, Araştırma ve Arkeometri Sempozyumu, Adil Özme (Ed.) Kültür ve Turizm Bakanlığı Yayınları. Ankara. 2016; p. 539–58.

Çelebi MA. II. Kılıçarslan Köşkü kurtarma kazısı işığında konya iç kalesi ve Anadolu Selçuklu Sarayı. Hacıgökmen M.A., Odabaşı Z., Solmaz S., Dursun Ş., Aksoy H., Dülgeroğlu S., (Eds.). Selçuklu Dönemi Saraylar ve Köşkler 1, Yapım: Selçuklu Belediyesi. Türkiye. 2021; p. 199–298.

Çeken M, Yavas A, Bozkurt T. Kubadabad Saray Külliyesi 2017 yılı kazı çalışmaları. 40. kazı sonuçları toplantısı 2. Cilt, T.C. Kültür ve Turizm Bakanlığı yayınları. Ankara. 2019; p. 701–16.

Özdeniz HH, Şimşir Z. Gevale Kalesi kazılarında ortaya çıkartılan seramiklerde kap formları. Selçuklu Medeniyeti Araştırmaları Dergisi. 2020;5(5):59–76. https://doi.org/10.47702/sematr.2020.4.

Gök D, Durak S. Erken Dönem Osmanlı Mimarisinde süsleme programının Bursa Yeşil Cami örneğinde incelenmesi. Paradoks Econ Sociol Policy J. 2018;14(2–1):19–42.

Martinet L, Ben Amara A, Pacheco C, Lemasson Q, Moignard B, Pichon L, Colomban P. Colored glaze tiles during the Ottoman Empire (beginning of the 15th to the/mid 16th century)? EMAC 2015 Proc., 13th European Meeting on Ancient Ceramics. Athens. 24–26th September 2015.

Caner-Saltik EN, Colomban P, Soulet V, Demirci S, Türkmenoglu A, Özcilingir-Akgün S, Bakirer Ö. Analysis of Anatolian medieval ceramic glazes XRD and non-destructive Raman micro-spectrometry. in proc. Archéométrie 2003, Bordeaux. 16–19 April 2003; p. 64.

Geçkinli AE, Şimşek G. Monokrom sırlı mozaik İran çinilerinin karakterizasyonu. In: Akyol AA, Özdemir K, editors. Türkiye’de Arkeometrinin Ulu Çınarları. Homer: Homer Publications; 2012. p. 205–12.

Raskovska A, Minceva B, Grupce O, Colomban P. Characterization of pottery from Rebuplic of Macedonia II. Raman and infrared analyses of glazed pottery finds from Skopsko Kale. J Raman Spectrosc. 2009;41(4):431–9. https://doi.org/10.1002/jrs.2463.

Tuna T. Ebu’l Kasım Çini Defteri’nin Teknolojik Analizi. Yüksek Lisans Tezi. M.Ü. Güzel Sanatlar Enstitüsü. İstanbul. 2002.

Güney BA, Caner E. Compositional investigation and phase identification of 13th century Anatolian Seljuk glazed tiles. Vib Spectrosc. 2020;106(102997):1–7. https://doi.org/10.1016/j.vibspec.2019.102997.

Güder Ü, Çeken M, Yavas A¸ Yalçın Ü, Raabe D. First evidence of crucible steel production in Medieval Anatolia, Kubadabad: a trace for possible technology exchange between Anatolia and Southern Asia. J Archaeol Sci. 2022;137(105529):1–14. https://doi.org/10.1016/j.jas.2021.105529.

Burlot J, Waksman SY, Bellot-Gurlet L, Simsek FG. The glaze production technology of an early Ottoman pottery (mid-14th (?) -16th century): the case of “miletus ware.” J Archaeol Sci Rep. 2020;29(102073):1–11. https://doi.org/10.1016/j.jasrep.2019.102073.

Matin M. A medieval stonepaste ceramic production site in Moshkin tepe, Iran ceramics, wasters, and manufacturing equipment. J Br Inst Persian Stud. 2022. https://doi.org/10.1080/05786967.2022.2080580.

Yeğingil Z, Freestone IC. Anadolu Toprağının Hazinesi Çini: Selçuklu ve Beylikler Çağı Çinileri. Kale Grubu Kültür Yayınları: İstanbul; 2007. p. 209–18.

Demirci Ş, Caner-Saltık EN, Türkmenoğlu A, Özçilingir-Akgün S, Bakırer Ö. Raw material characteristics and technological properties of some medieval glazed ceramics and tiles in Anatolia. Key Eng Mater. 2004;264–268:2395–8. https://doi.org/10.4028/www.scientific.net/KEM.264-268.2395.

Yalçın Yastı Ş. Konya Kubad Abad çinilerinin arkeometrik karakterizasyonu ve benzer çinilerin araştırılması. Doktora Tezi. Selçuk Üniversitesi Fen Bilimleri Enstitüsü. Konya. 2011; p. 1–12.

Freestone I, Yegingil Z, Arik R. Scientific analysis of glazed tile from the Seljuq palace of Kubad-Abad, Lake Beysehir, Turkey. Scientific Research on Historic Asian Ceramics. In: proceedings of 4th Forbes symposium. Washington, DC. 2009; p. 3–8.

Tite MS, Wolf S, Mason RB. The technological development of stonepaste ceramics from the Islamic Middle East. J Archaeol Sci. 2011;38:570–80. https://doi.org/10.1016/j.jas.2010.10.011.

Peacock ACS. Islam, literature and society in Mongol Anatolia. In: Dale SF, editor. The muslim empires of the Ottomans, Safavids, and Mughals. Cambridge: Cambridge University Press; 2009.

Colomban P. Glass, pottery and enamelled objects: identification of their technology and origin. In: Richardson E, Garside P, editors. RSC conservation science: heritage materials. 2nd ed. Cambridge: The Royal Society of Chemistry; 2022.

Casasola R, Rincón JM, Romero M. Glass–ceramic glazes for ceramic tiles: a review. J Mater Sci. 2012;47:553–82. https://doi.org/10.1007/s10853-011-5981-y.

Lu P, Xu X, Yi W, German RM. Porosity effect on densification and shape distortion in liquid phase sintering. Mater Sci Eng A. 2001;318(1–2):111–21.

Danninger H, de Oro Calderon R, Gierl-Mayer C. Fundamentals of sintering: liquid phase sintering. In: Caballero FG, editor. Encyclopedia of materials: metals and alloys. Elsevier: Oxford; 2022. p. 481–92.

Öztürk Ç, Akpınar S, Tarhan M. Investigation of the usability of Sille stone as additive in floor tiles. J Aust Ceram Soc. 2021;57:567–77. https://doi.org/10.1007/s41779-021-00562-9.

Martín-Márquez J, Ma Rincón J, Romero M. Effect of firing temperature on sintering of porcelain stoneware tiles. Ceram Int. 2008;34(8):1867–73.

Salinas E, Pradell T, Molera J. Glaze production at an early Islamic workshop in al-Andalus. Archaeol Anthropol Sci. 2019;11:2201–13.

Tite MS, Freestone I, Mason R, Molera J, Vendrell-Saz M, Wood N. Lead glazes in antiquity-methods of production and reasons for use. Archaeometry. 1998;40(2):241–60. https://doi.org/10.1111/j.1475-4754.1998.tb00836.x.

Simsek G, Unsalan O, Bayrakta K, Colomban Ph. On-site pXRF analysis of glaze composition and colouring agents of “Iznik” tiles at Edirne Mosques (15th and 16th-centuries). Ceram Int. 2019;45(1):595–605.

Demirsar Arli B, Simsek Franci G, Kaya S, Arli H, Colomban Ph. Portable X-ray fluorescence (p-XRF) uncertainty estimation for glazed ceramic analysis: case of Iznik tiles. Heritage. 2020;3(4):1302–29. https://doi.org/10.3390/heritage3040072.

Simsek G, Demirsar Arli B, Kaya S, Colomban P. On-site pXRF analysis of body, glaze and coloring agents of the tiles at the excavation site of Iznik kilns. J Eur Ceram Soc. 2019;39:2199–209. https://doi.org/10.1016/j.jeurceramsoc.2019.01.050.

Çeken M. Anadolu Toprağının Hazinesi Çini: Selçuklu ve Beylikler Çağı Çinileri. İstanbul: Kale Grubu Kültür Yayınları; 2007. p. 13–25.

Öztürk Ç, Kuşoğlu İM, Henderson J. Anadolu’da cam yapım teknolojisi arkeometrik sonuçları: Helenistik’ten Osmanlı dönemine. International Fine Arts Symposium (IFAS). 12–13 November, Konya, 2015; p. 626–31.

Muhmed A, Wanatowski D. Effect of lime stabilisation on the strength and microstructure of clay. IOSR J Mech Civil Eng. 2013;6(3):87–94.

Wiśniewska K, Kłosek-Wawrzyn E, Lach R, Pichór W. Influence of the grain size distribution of the limestone additives on the color properties and phase composition of sintered ceramic materials based on cream-firing clays. Materials. 2022;15(7):2694. https://doi.org/10.3390/ma15072694.

Colomban Ph. On-site Raman identification and dating of ancient glasses: a review of procedures and tools. J Cult Herit. 2008;9:e55–60. https://doi.org/10.1016/j.culher.2008.06.005.

Colomban P. Raman spectroscopy in archaeology and art history. London: Royal Society of Chemistry; 2005. p. 192.

Colomban P, Laveaucoupet R, Milande V. On-site Raman spectroscopic analysis of Kütahya fritwares. J Raman Spectrosc. 2005;36:857–63. https://doi.org/10.1002/jrs.1372.

Colomban Ph, Tournie A, Bellot-Gurlet L. Raman identification of glassy silicates used in ceramics, glass and jewellery: a tentative differentiation guide. J Raman Spectrosc. 2006;37(8):841–52. https://doi.org/10.1002/jrs.1515.

Liem NQ, Thanh NT, Colomban Ph. Reliability of Raman micro-spectroscopy in analysing ancient ceramics: the case of ancient Vietnamese porcelain and celadon glazes. J Raman Spectrosc. 2002;33:287–94. https://doi.org/10.1002/jrs.854.

Colomban Ph, Treppoz F. Identification and differentiation of ancient and modern european porcelains by Raman macro- and micro-spectroscopy. J Raman Spectrosc. 2001;32(2):93–102. https://doi.org/10.1002/jrs.678.

Colomban Ph, Tournié A. On-site Raman identification and dating of ancient/modern stained glasses at the Sainte-Chapelle, Paris. J Cult Herit. 2007;8(3):242–56. https://doi.org/10.1016/j.culher.2007.04.002.

Colomban Ph, Robert I, Roche C, Sagon G, Milande V. Identification desporcelains “tendres” du 18ème siècle par spectroscopie Raman: Saint-Cloud. Chantilly Mennecy et Vincennes/Sèvres Revue d’Archéométrie. 2004;28:153–67.

Simsek G, Geckinli AE. An assessment study of tiles from Topkapı Palace Museum with energy-dispersive X-ray and Raman spectrometers. J Raman Spectrosc. 2012;43(7):917–27. https://doi.org/10.1002/jrs.3108.

Colomban Ph. Raman spectrometry, a unique tool to analyse and classify ancient ceramics and glasses. Appl Phys A. 2004;79(2):167–70. https://doi.org/10.1007/s00339-004-2512-6.

Zanelli C, Raimondo M, Dondi M, Guarini G, Cavalcante PMT. Sintering mechanisms of porcelain stoneware tiles. En: VIII World Congress on Ceramic Tile Quality, Castellon de la Plana, Espana. 2004; p. 247–259.

Venturelli C. Heating microscopy and its applications. Micros Today. 2011;19(1):20–5. https://doi.org/10.1017/S1551929510001185.

Montanari F, Miselli P, Leonelli C, Boschetti HJ, Baraldi P. Calibration and use of the heating microscope for indirect evaluation of the viscosity and meltability of archeological glasses. Appl Glass Sci. 2014;5:161–77. https://doi.org/10.1111/ijag.12038.

Turkmen O, Kucuk A, Akpinar S. Effect of wollastonite addition on sintering of hard porcelain. Ceram Int. 2015;41(4):5505–12. https://doi.org/10.1016/j.ceramint.2014.12.126.

Acknowledgements

We would like to thank The Konya Museum Directorate for permitting us to study the tiles and Mr Ömer Faruk TÜRKAN, Mr Naci BAKIRCI and Mr Mehmet Ali ÇELEBİ for their contributions.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

ÇÖ, conceived and designed the analyses, collected the data, performed analyses and wrote the main manuscript text. GŞF, performed Raman and WD-XRF analyses and examined the cross-section of the tiles with a stereo microscope. İMK, performed XRD analysis of the tile bodies. All authors discussed the results and contributed to the final manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Öztürk, Ç., Şimşek Franci, G. & Kuşoğlu, İ.M. An archaeometric assessment study of Seljuk period glazed tiles from Kılıçarslan Square (Konya, Turkey). Herit Sci 10, 174 (2022). https://doi.org/10.1186/s40494-022-00806-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-022-00806-2