Abstract

Background

Aryl sulfides have significant importance from biological and pharmaceutical aspects. Transition metal-catalyzed carbon-sulfur cross-coupling reaction represents an important tool for the synthesis of sulfides. Among various transition metals, copper salts or oxides have found vast applicability.

Results

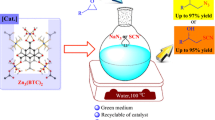

A simple procedure for the preparation of poly-ionic amberlite resins embedded with copper oxide nanoparticles (CuO NPs) (denoted as CuO@ARF) has been developed, characterized, and employed for the first time as a heterogeneous ligand-free catalyst for ‘on-water’ C-S cross-coupling reaction. The NPs of CuO with an average size (approximately 2.6 nm), as determined from high resolution transmission electron microscopy (HRTEM) images, are found to be a potentially active, chemoselective, and recyclable catalyst for the preparation of symmetrical and unsymmetrical aryl sulfides. Recycling of the catalyst was performed successfully for five consecutive runs, and apparently no leaching was observed in a hot filtration test. Excellent chemoselectivity between iodo- and bromo-arene has been exploited in step-wise C-S and C-N couplings to synthesize bioactive heterocyclic scaffold phenothiazine.

Conclusions

An efficient method is established for the C-S cross-coupling reaction using heterogeneous catalyst CuO@ARF under ligand-free on-water condition. The catalyst is highly chemoselective among different aryl halides, which has been demonstrated in the synthesis heterocyclic scaffold phenothiazine. Furthermore, it is recyclable for five consecutive runs examined.

On-water C-S coupling using new heterogeneous nano-catalyst (CuO@ARF)

Similar content being viewed by others

Background

The carbon-sulfur bonds are prevalent present in numerous medicinally important natural products [1]-[3]. Indeed, a number of drugs in various therapeutic uses such as HIV, cancer, diabetes, inflammatory, Alzheimer's, and Parkinson's diseases contain the aryl sulfide functional group [4]-[7]. A few biologically active compounds possessing a C-S bond are represented in Figure 1. For example, phenothiazines are an important class of organic compounds finding wide applications as drugs, insecticides, inhibitors of polymerization, antioxidants, paints, spectroscopic probes, etc. [8]. Therefore, in the recent era, the sp2C-S bond formation has been the subject of intense study in organic synthesis and medicinal chemistry, and researchers develop diverse mild cross-coupling methodologies for these pharmaceuticals.

The conventional methods for the C-S bond formation involve reduction of aryl sulfones or aryl sulfoxides using strong reducing agents like DIBAL-H or LiAlH4[9]. Besides, on-water C-S bond formation has been reported via thiol addition to α,β-unsaturated carbonyl compounds at room temperature [10]. In 1980, Migita et al. first showed the Pd-catalyzed thiation of aryl bromides using Pd(PPh3)4[11]. Subsequently, other metals like nickel [12],[13], copper [12],[14], cobalt [15], iron [16], rhodium [17], manganese [18], and indium [19] have also been employed, though in much less extent, as compared to other C-X (X = C, O, N, P) coupling reactions. This is possibly due to the notion that sulfur might act as the poison to suppress the catalytic activity through strong coordinating and adsorptive properties [20]. However, the last two decades have witnessed several new transition metal-based catalytic systems for the C-S coupling reactions between aryl halides and thiols. Amongst various transition metals, copper has been considered as the most useful for the C-S coupling reactions due to its special redox properties and cost-effectiveness. Many strategies have been successful by using homogeneous copper salts in the presence of suitable electron-rich and precious ligands for the C-S coupling reactions [21],[22].

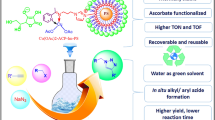

On the other hand, nano-structured materials with high surface areas have been investigated as effective catalysts for various organic coupling reactions [23]. Catalysis of organic reactions by metal NPs supported on a suitable polymeric matrix offers the advantages of high catalytic activity, simplified isolation of the product, easy recovery, and recycling of the catalyst. Copper oxide nanoparticles (CuO NPs) are a good choice and indeed useful catalyst in the C-S coupling reaction between aryl halide and thiols [24]-[26]. However, previous on-water C-S coupling reactions involving copper species like CuI-TBAB [27], CuCl [28], or other metal species like Bi2O3[29], CoCl2.6H2O [30], or FeCl3.6H2O-bipyridyl complexes [31], etc. afford thioethers without easy recovery of the catalyst and recyclability. Direct use of CuO either in bulk or NPs requires organic solvents other than water and gave relatively poor yields in C-S coupling reaction. Considering our experience in the field of developing polymer-supported metal NPs as the heterogeneous catalyst in various coupling reactions, [32],[33] and in conjunction with our interest in the synthesis of various biologically important heterocyclic scaffolds mediated over solid supports, [34],[35] we were interested to develop polymer-supported CuO NPs and to use it as the catalyst in ‘on-water’ C-S coupling reaction between aryl halide and thiols.

We report herein our studies that constitute simple preparation and characterization of poly-ionic amberlite resins embedded with CuO NPs (CuO@ARF), which efficiently catalyze the C-S cross-coupling reaction under on-water and ligand-free conditions. Further application of this catalyst has been demonstrated in the synthesis of phenothiazine - an important structural motif of several potentially useful drugs and also used as chemosensors [36].

Methods

Amberlite resin formate (ARF) was prepared from commercially available inexpensive amberlite resin chloride by an ion-exchange process as reported from this laboratory [37]. A mixture of ARF resin beads and Cu(OAc)2.H2O in DMF (50 mg g−1 of ARF) was heated at 110°C in a Teflon-capped sealed tube for 30 min with occasional gentle shaking. White ARF beads turned brownish in color during the process. Finally, these resin beads were filtered off, washed with water and acetone, dried, and characterized by Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD), and transmission electron microscopy (TEM) analysis, and the copper content of the composite was estimated by atomic absorption spectroscopy (AAS). The XRD and TEM analyses suggested the presence of CuO NPs distributed on the surface of ARF, and we referred the as-synthesized nanocomposite material as CuO@ARF.

Results and discussion

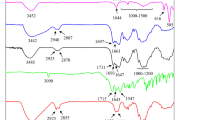

At first, the presence of copper in the resin composite was measured by the AAS study. For this purpose, the sample (100 mg) was digested with concentrated HNO3 (1 mL) and Cu content was estimated to be 0.145 mmol g−1 of the resin-copper nanocomposite. The FT-IR spectra of CuO@ARF were recorded and compared with those of ARF (Figure 2). In the case of a similar heterogeneous Pd or bimetallic Pd/Cu nanocomposites, as developed from this laboratory, a significant increase in the stretching frequency of the carboxylate anion (HCOO¯) was observed [32],[33]. Here, apparently no change of symmetric and anti-symmetric stretching vibrations (for the HCOO¯) was observed and appeared respectively at about 1,345 and 1,593 cm−1 for both ARF and CuO@ARF species (Figure 2). However, the specific IR absorption bands of CuO at 606 and 525 cm−1 might overlap with those of ARF in the similar region [38].

We therefore examined the powder XRD patterns of ARF and those of CuO@ARF, as shown in Figure 3. The ARF resins are amorphous in nature, and the Bragg diffraction patterns of CuO@ARF indicate the presence of cupric oxide (CuO). The JCPDS peak positions of the CuO@ARF nanocomposite with relative intensities are in good agreement (Figure 3b). The presence of XRD peaks at 2θ of 35.39°, 38.29°, 38.99°, 57.91°, and 61.64° suggested the presence of CuO ( 11), (111), (200), (202), and ( 13) planes, respectively (JCPDS#01-089-2531). Further examination of high resolution TEM (HRTEM) images of the CuO@ARF at different magnifications (Figure 4a,b) suggested that the CuO NPs are embedded on the resin polymeric matrices with an average size around 2.6 nm (Figure 4c).

Catalytic activity of CuO@ARF

In order to evaluate the catalytic activity of this newly developed nanocomposite (CuO@ARF) in C-S cross-coupling reaction between aryl halide and thiol, we performed a model study by taking a mixture of 4-iodoanisole and benzenethiol (in 1:1.2 ratios) and the catalyst (200 mg mmol−1 of aryl iodide) in water (Table 1). The first reaction in the presence of a base (K2CO3) at 100°C did afford the desired unsymmetrical sulfane but with a modest yield (62%) (Table 1, entry 1). Considering that the modest conversion might be due to the poor solubility of aryl iodide in water, we used an additive - tetrabutylammonium bromide (TBAB), in equimolar quantity. This afforded the corresponding thioether in fairly good yield (83%; entry 2). Further improvement was achieved by using the catalytic amount of sodium dodecyl sulfate (SDS; 10 mol%), [39] which furnished the desired product in 90% isolated yield (entry 3). While there was no cross-coupling observed at room temperature, reaction carried out at 60°C or in the absence of the base produced the sulfane in 56% to 68% isolated yields (entries 4 to 6). We also tried the reaction in DMF at 100°C, which did not produce the desired sulfane in very good yield (entry 7). In each case, a small quantity of the diphenylsulfide (≤5%) as the side product was also formed.

Minimum loading of the catalyst

After optimizing the reaction conditions, we examined the minimum amount of the catalyst loading that is required to obtain effective conversion to sulfane. Experiments were performed with 4-iodoanisole (1 mmol) in the presence of varying quantities of CuO@ARF (from 50 mg to 250 mg; i.e., 0.46 mg to 2.30 mg of copper mmol−1 of iodoarene) and the results are shown in Figure 5. Conversions to the thioether at different time intervals were measured by high-performance liquid chromatography (HPLC) and the plot of percent conversion (±2%) versus time (h) revealed that minimum 200 mg of the catalyst (approximately 1.8 mg of copper) mmol−1 of iodoarene can give rise to the best result. In each case, reaction was continued up to 24 h and HPLC analysis showed no appreciable changes in the conversion (Figure 5 was plotted up to 12 h).

The optimized reaction conditions were then employed with different iodoarenes and other aromatic halides to couple with variety of aryl thiols to examine the scope and limitations of our catalyst for on-water C-S cross-coupling reaction. In general, it was observed that the cross-coupling reaction was successful producing corresponding diaryl sulfide in good to excellent yields. The results are presented in Table 2. Iodoarenes with both activated (methoxy, methyl) and deactivated functional groups (nitro or acetyl) effectively underwent C-S cross-coupling with different aryl thiols (entries 1 to 5). On the other hand, similar coupling reactions with bromo- and chlorobenzenes, including p-chloroacetophenone were not successful (entries 6 and 7). Increasing the catalyst loading and changing the base did not facilitate the C-S cross-coupling of p-bromotoluene (entry 8). The selectivity however might be useful for substrates bearing different halides. Thus, iodobromoarenes and iodochloroarene were subjected to coupling with aryl thiols in the presence of this heterogeneous catalyst affording highly chemoselective iodo-coupled product only (entries 9 to 11). Substituted thiophenol like 2,5-dimethylbenzenethiol underwent smooth reactions giving the corresponding unsymmetrical diarylsulfide in 89% isolated yield (entry 12). Aliphatic thiols also gave cross-coupling products without any difficulty but relatively in lower yields as compared to aromatic thiols (entries 13 to 15), which might be attributable to the fact that aliphatic thiols are less reactive than aromatic thiols [40]. Bis-couplings were performed equally efficiently starting from 1,3-diiodobenzene and p-tolylthiol and affording the desired 1,3-bis(p-tolylthio)benzene as the only product in 79% isolated yield (entry 16). It may be mentioned that only benzenethiol and 4-tolylthiol gave a minor quantity of corresponding disulfides during the reaction (≤5%), while in other cases, no disulfide was detected on thin-layer chromatography (TLC) or by HPLC analysis.

As reported previously [26], the mechanism of the resin embedded CuO-catalyzed C-S coupling reaction is believed to proceed through the oxidative addition followed by reaction with thiol and then reductive elimination steps (CuII → CuIII → CuII). The role of the additive SDS is presumably to solubilize the organic substrates in an aqueous medium [41],[42]. Further beneficial assistance of the ‘microreactors’ formed by the surfactant like SDS in water medium organic reactions, as observed in other cases, cannot be ruled out [43]. In addition, the role of water might be attributed to the H-bonding (HB) effect, as reported previously on other occasions [44], has also been noticed in our cases. Thus, we isolated the cross-coupled product in higher yield performing the reaction in an aqueous medium as compared to in DMF (Table 1, entries 3 and 7).

Leaching of any metallic species from the amberlite resin polymeric matrices during or after the reaction was tested following the literature procedure [33],[45]. Accordingly, the reaction mixture of the C-S cross-coupling between 4-iodoanisole and thiophenol is filtered off to separate out the solid catalysts after 2 h in hot condition, and the filtrate was analyzed by HPLC (approximately 43% conversion). The AAS analysis of the filtrate solution did not show the presence of any copper species. Moreover, further continuing the reaction by heating the liquid phase at 100°C for another 6 h in the absence of any added catalyst (CuO@ARF) did not afford any appreciable conversion (HPLC analysis). These observations signify that any copper species might not be leached out from the heterogeneous support during the initial 2 h of the reaction (Figure 6).

One of the important factors for a heterogeneous catalyst lies in its efficiency for recycling. We investigated the reusability of CuO@ARF in the reaction between 4-iodoanisole and thiophenol again as the model case. After completion of the reaction, resin beads were filtered off from the reaction mixture, washed thoroughly with water followed by acetone (two times), and then dried under vacuum. The catalyst was reused in five consecutive runs including the first run. Gratifyingly, there was no considerable loss of the catalytic efficiency observed (Figure 7).

Since the present catalytic system is highly selective to aryl iodides only (i.e., the first oxidative addition to the sp2C-I bond), we decided to utilize this chemoselectivity between iodo- and bromo-substituents attached to the aryl moiety. Thus, a reaction of 1,2-bromoiodobenzene with 2-aminothiophenol in the presence of the catalyst CuO@ARF under similar conditions in water was performed. The C-S coupling occurred selectively at the sp2C-I bond, and we obtained 2-(2-bromophenylthio)benzene in 82% yield (Scheme 1). Further intramolecular Buchwald-Hartwig type coupling between amino-and bromo-substituents attached with two aromatic rings under Pd-BINAP catalyzed condition was carried out to afford phenothiazine in 84% isolated yield. The C-N coupling can also be accomplished by using the new catalyst (CuO@ARF) in the presence of L-proline as the ligand (Scheme 1) [46]. The 1H nuclear magnetic resonance (NMR) spectra run in DMSO-D6 and DMSO-D6-D2O confirmed formation of phenothiazine with the labile NH proton appeared at δ 8.5 ppm (see Additional file 1). We also performed the intramolecular Buchwald coupling in a water medium using both catalytic systems. Although the reaction works well with comparative yield of the phenothiazine in the case of using Pd2(dba)3, the use of CuO@ARF as the catalyst however does not give a satisfactory yield of the desired cyclic product.

A comparison chart of the efficiency of the present catalytic system with other metal-based ‘on-water’ catalytic systems reported in the literature showing advantages in terms of low loading, high efficiency, stability of the catalyst, recyclability, etc. has been presented in Table 3.

Conclusions

Our studies established that poly-ionic resin-supported CuO NPs (CuO@ARF) are an efficient catalyst in the C-S coupling reaction under ligand-free ‘on-water’ conditions. Low loading of the catalyst, recyclability without leaching, and chemoselectivity amongst aromatic halides are notable features. Further application of the chemoselectivity has been demonstrated in the synthesis of bioactive heterocyclic scaffold phenothiazine. Considering the inexpensive catalytic system along with the application to the synthesis of medicinally important structural scaffold, this heterogeneous catalyst and greener method can find wider applications in organic synthesis.

Experimental

Amberlite IRA 900 (chloride form) was purchased from Acros Organics, Geel, Belgium, and used after washing with water and acetone followed by drying under vacuum. Cupric acetate was purchased from S.D. Fine Chem. Limited, Mumbai, India, and other chemicals were purchased and used directly. For column chromatography, silica (60 to 200 μm) (Sisco Research Laboratories, Mumbai, India), and for TLC, Merck plates coated with silica gel 60, F254 were used (Merck & Co., Inc., Whitehouse Station, USA). FT-IR spectra were recorded in FT-IR-8300 Shimadzu spectrophotometer (Shimadzu, Kyoto, Japan). NMR spectra were taken in CDCl3 using Bruker Avance AV-300 spectrometer (Bruker AXS, Inc., Yokohama-shi, Japan) operating for 1H at 300 MHz and for 13C at 75 MHz. The spectral data were measured using TMS as the internal standard (for 1H) and CDCl3 (for 13C). AAS measurements were made using Varian SpectrAA 50B instrument (Varian Medical Systems, Melbourne, Australia). Progress of the reaction was monitored by HPLC (1260 Infinity, Agilent Technologies, Santa Clara, USA), column: ZORBAX Rx-SIL (4.6 × 150 mm, 5 μm), eluent: n-hexane (flow rate 2 mL min−1). The XRD studies of the powder samples were done using the Rigaku SmartLab (Shibuya-ku, Japan) (9 kW) diffractometer using CuKα radiation. HRTEM of the samples was recorded with JEOL JEM-2100 F (FEG) (JEOL Ltd., Akishima-shi, Japan) operating at 200 kV.

Preparation of CuO@ARF

To a solution of Cu(OAc)2,.H2O (50 mg, 0.25 mmol) in DMF (5 mL) was added ARF (1 g), and the mixture taken in a Teflon-capped sealed tube was heated at 110°C for 30 min with occasional gentle shaking. The supernatant liquid became completely colorless by this time, and the greyish beads of ARF visibly turned brownish. The mixture was cooled to room temperature, and the resin beads were filtered off and washed repeatedly with water (3 × 5 mL) and acetone (2 × 5 mL). Resulting brown beads were dried under vacuum and used for analyses and evaluation of catalytic activity.

General conditions for C-S cross-coupling reaction

To a suspension of CuO@ARF (200 mg) in water (3 mL) were added aryl halide (1 mmol), thiol (1.2 mmol), K2CO3 (1.1 mmol), and SDS (10 mol%), and the reaction mixture was heated in a screw-capped sealed tube at 100°C for several hours as mention in Table 2. Proceeding of the reaction was monitored by TLC at time intervals. After completion, the mixture was cooled, diluted with water (5 mL), and then filtered through a cotton bed to separate out the resin beads. The resin beads were washed with ethyl acetate (2 mL), and the filtrate was extracted with ethyl acetate (3 × 10 mL). The combined organic layer was dried over anhydrous Na2SO4 and concentrated under vacuum. The residue obtained was purified by column chromatography using light petroleum as the eluent. All products were identified on the basis of spectral data (1H and 13C NMR) and also compared with reported melting point (for solid compounds and as available) (see Additional file 1).

The resin beads separated out from the reaction mixture were successively washed with water (3 × 5 mL) and acetone (2 × 5 mL) and then dried under vacuum for use in the next batch of recycle run.

Preparation of phenothiazine from selective iodo-coupled product (Table 2, entry 17) using Pd-BINAP catalyst

To a mixture of 2-(2-bromophenylthio)benzeneamine (1 mmol, 280 mg) in toluene were added tBuOK (1.5 mmol, 168 mg), Pd2(dba)3 (2 mol%), and BINAP (4 mol%). The reaction mixture taken in a screw-capped sealed tube was heated at 100°C for 4 h. After cooling, the reaction mixture was diluted with water (5 mL) and extracted with ethyl acetate (3 × 10 mL). The combined extracts were washed with brine, dried (Na2SO4), and evaporated. The residue was purified over a silica gel column to obtain white crystals of phenothiazine (167 mg, 84%), characterized by 1H and 13C NMR, and compared with literature data (see Additional file 1).

10H-phenothiazine [46], m.p. 185°C to 186°C (Lit. m.p. 186°C to 187°C). 1H NMR (DMSO-d6, 300 MHz): δ/ppm 6.72 to 6.77 (m, 4H, ArH), 6.89 to 7.01 (m, 4H, ArH), 8.58 (s, 1H, NH) 13C NMR (DMSO-d6, 75 MHz): δ/ppm 114.4, 116.4, 121.8, 126.3, 127.5, and 142.1.

Preparation of phenothiazine from selective iodo-coupled product (Table 2, entry 17) using CuO@ARF catalyst

To a mixture of 2-(2-bromophenylthio)benzeneamine (1 mmol, 280 mg) in dimethyl sulfoxide were added tBuOK (1.5 mmol, 168 mg), CuO@ARF (200 mg, 1.8 mg of copper, 2.83 mol% Cu) and L-proline (5.66 mol%). The reaction mixture taken in a screw-capped sealed tube was heated at 100°C for 48 h. After cooling, the reaction mixture was diluted with water (5 mL) and extracted with ethyl acetate (3 × 10 mL). The combined extracts were washed with brine, dried (Na2SO4), and evaporated. The residue was purified over a silica gel column to obtain white crystals of phenothiazine (143 mg, 72%), characterized by 1H and 13C NMR and compared with literature data (see Additional file 1).

Additional file

References

Procter DJ: The synthesis of thiols, selenols, sulfides, selenides, sulfoxides, selenoxides, sulfones and selenones. J Chem Soc Perkin Trans 2000, 1: 835–871. 10.1039/a901128e

Liu L, Stelmach JE, Natarajan SR, Chen M-H, Singh SB, Schwartz CD, Fitzgerald CE, O'Keefe SJ, Zaller DM, Schmatz DM, Doherty JB: SAR of 3,4-dihydropyrido[3,2-d]pyrimidone p38 inhibitors. Bioorg Med Chem Lett 2003, 13: 3979–3982. 10.1016/j.bmcl.2003.08.059

Jones DN: 3. In Comprehensive Organic Chemistry, vol 3. Edited by: Barton DH, Ollis DW. Pergamon, New York; 1979.

Kaldor SW, Kalish VJ, Davies JF II, Shetty BV, Fritz JE, Appelt K, Burgess JA, Campanal KM, Chirgadze NY, Clawson DK, Dressman BA, Hatch SD, Khalil DA, Kosa MB, Lubbehusen PP, Muesing MA, Patick AK, Reich SH, Su KS, Tatlock JH: Viracept (nelfinavir mesylate, AG1343): a potent, orally bioavailable inhibitor of HIV-1 protease. J Med Chem 1997, 40: 3979–3985. 10.1021/jm9704098

De Martino G, Edler MC, La Regina G, Cosuccia A, Barbera MC, Barrow D, Nicholson RI, Chiosis G, Brancale A, Hamel E, Artico M, Silvestri R: New arylthioindoles: potent inhibitors of tubulin polymerization. 2. Structure-activity relationships and molecular modeling studies. J Med Chem 2006, 49: 947–954. 10.1021/jm050809s

Liu G, Huth JR, Olejniczak ET, Mendoza F, Fesik SW, von Geldern TW: Novel p -arylthio cinnamides as antagonists of leukocyte function-associated antigen-1/intracellular adhesion molecule-1 interaction. 2. Mechanism of inhibition and structure-based improvement of pharmaceutical properties. J Med Chem 2001, 44: 1202–1210. 10.1021/jm000503f

Nielsen SF, Nielsen EØ, Olsen GM, Liljefors T, Peters D: Novel potent ligands for the central nicotinic acetylcholine receptor: synthesis, receptor binding, and 3D-QSAR analysis. J Med Chem 2000, 43: 2217–2226. 10.1021/jm990973d

Korth C, May BCH, Cohen FE, Prusiner SB: Acridine and phenothiazine derivatives as pharmacotherapeutics for prion disease. Proc Natl Acad Sci U S A 2001, 98: 9836–9841. 10.1073/pnas.161274798

Hickman RJS, Christie BJ, Guy RW, White T: Synthesis of aromatic S-substituted derivatives of N -acetyl-L-cysteine. Aust J Chem 1985, 38: 899–904. 10.1071/CH9850899

Khatik GL, Kumar R, Chakraborti AK: Catalyst-free conjugated addition of thiols to α, β-unsaturated carbonyl compounds in water. Org Lett 2006, 8: 2433–2436. 10.1021/ol060846t

Migita T, Shimizu T, Asami Y, Shiobara J, Kato Y, Kosugi M: The palladium catalyzed nucleophilic substitution of aryl halides by thiolate anions. Bull Chem Soc Jpn 1980, 53: 1385–1389. 10.1246/bcsj.53.1385

Eichman CC, Stambuli JP: Transition metal catalyzed synthesis of aryl sulfides. Molecules 2011, 16: 590–608. 10.3390/molecules16010590

Guan P, Cao C, Liu Y, Li Y, He P, Chen Q, Liu G, Shi Y: Efficient nickel/N-heterocyclic carbene catalyzed C–S cross-coupling. Tetrahedron Lett 2012, 53: 5987–5992. 10.1016/j.tetlet.2012.08.055

Chen C-K, Chen Y-W, Lin C-H, Lin H-P, Lee C-F: Synthesis of CuO on mesoporous silica and its applications for coupling reactions of thiols with aryl iodides. Chem Commun 2010, 46: 282–284. 10.1039/b918117b

Wong YC, Jayanth TT, Cheng CH: Cobalt-catalyzed aryl-sulfur bond formation. Org Lett 2006, 8: 5613–5616. 10.1021/ol062344l

Correa A, Carril M, Bolm C: Iron-catalyzed S-arylation of thiols with aryl iodides. Angew Chem Int Ed 2008, 47: 2880–2883. 10.1002/anie.200705668

Lai CS, Kao HL, Wang YJ, Lee CF: A general rhodium-catalyzed cross-coupling reaction of thiols with aryl iodides. Tetrahedron Lett 2012, 53: 4365–4367. 10.1016/j.tetlet.2012.06.054

Liu T-J, Yi C-L, Chan C-C, Lee C-F: Manganese-catalyzed cross-coupling of thiols with aryl iodides. Chem Asian J 2013, 8: 1029–1034. 10.1002/asia.201300045

Reddy VP, Kumar AV, Swapna K, Rao KP: Nano indium oxide as a recyclable Catalyst for C-S cross-coupling of thiols with aryl halides under ligand free conditions. Org Lett 2009, 11: 1697–1700. 10.1021/ol900009a

Hegedus LL, McCabe RW (1984) ᅟ. In: Catalysis Poisoning. Marcel Dekker, New York

Chen YJ, Chen HH: 1,1,1-Tris(hydroxymethyl)ethane as a new, efficient, and versatile tripod ligand for copper-catalyzed cross-coupling reactions of aryl iodides with amides, thiols, and phenols. Org Lett 2006, 8: 5609–5612. 10.1021/ol062339h

Bates CG, Gujadhur RK, Venkataraman D: A general method for the formation of aryl-sulfur bonds using copper(I) catalysts. Org Lett 2002, 4: 2803–2806. 10.1021/ol0264105

Heiz U: Landman U Nanocatalysis. Springer–Verlag, Springer Berlin; 2007.

Kamal A, Srinivasulu V, Murty JNSRC, Shankaraiah N, Nagesh N, Reddy TS, Rao AVS: Copper oxide NPs supported on graphene oxide- catalyzed S-arylation: an efficient and ligand-free synthesis of aryl sulfides. Adv Synth Catal 2013, 355: 2297–2307. 10.1002/adsc.201300416

Schwab RS, Singh D, Alberto EE, Piquini P, Rodrigues OED, Braga AL: C–S cross-coupling of thiols with aryl iodides under ligand-free conditions using nano copper oxide as a recyclable catalyst in ionic liquid. Catal Sci Technol 2011, 1: 569–573. 10.1039/c1cy00091h

Rout L, Sen TK, Punniyamurthy T: Efficient CuO-nanoparticle-catalyzed C-S cross-coupling of thiols with iodobenzene. Angew Chem Int Ed 2007, 46: 5583–5586. 10.1002/anie.200701282

Rout L, Saha P, Jammi S, Punniyamurthy T (2008) Efficient copper(I)-catalyzed C–S cross coupling of thiols with aryl halides in water. Eur J Org Chem 2008ᅟ:640–643

Carril M, SanMartin R, Dominguez E, Tellitu I: Simple and efficient recyclable catalytic system for performing copper-catalysed S-arylation reactions in the presence of water. Chem Eur J 2007, 13: 5100–5105. 10.1002/chem.200601737

Malik P, Chakraborty D: Bi(III)-catalyzed C-S cross-coupling reaction. Appl Organomet Chem 2012, 26: 557–561. 10.1002/aoc.2871

Lan M-T, Wu W-Y, Huang S-H, Luo K-L, Tsai F-Y: Reusable and efficient CoCl 2 .6H 2 O/cationic 2,2′-bipyridyl system-catalyzed S-arylation of aryl halides with thiols in water under air. RSC Adv 2011, 1: 1751–1755. 10.1039/c1ra00406a

Wu WY, Wang JC, Tsai FY: A reusable FeCl 3 · 6H 2 O/cationic 2,2′-bipyridyl catalytic system for the coupling of aryl iodides with thiols in water under aerobic conditions. Green Chem 2009, 11: 326–329. 10.1039/b820790a

Basu B, Das S, Das P, Mandal B, Banerjee D, Almqvist F (2009) Palladium supported on a polyionic resin as an efficient, ligand-free, and recyclable catalyst for Heck, Suzuki-Miyaura, and Sonogashira reaction. Synthesis ᅟ:1137–1146

Sengupta D, Saha J, De G, Basu B: Pd/Cu bimetallic NPs embedded in macroporous ion-exchange resins: an excellent heterogeneous catalyst for the Sonogashira reaction. J Mater Chem A 2014, 2: 3986–3992. 10.1039/c3ta14916a

Paul S, Basu B: Synthesis of libraries of quinoxalines through eco-friendly tandem oxidation–condensation or condensation reactions. Tetrahedron Lett 2011, 52: 6597–6602. 10.1016/j.tetlet.2011.09.141

Paul S, Basu B: Highly selective synthesis of libraries of 1,2-disubstituted benzimidazoles using silica gel soaked with ferric sulfate. Tetrahedron Lett 2012, 53: 4130–4133. 10.1016/j.tetlet.2012.05.129

Rhee H-W, Choi SJ, Yoo SH, Jang YO, Park HH, Pinto RM, Cameselle JC, Sandoval FJ, Roje S, Han K, Chung DS, Suh J, Hong J-I: A bifunctional molecule as an artificial flavin mononucleotide cyclase and a chemosensor for selective fluorescent detection of flavins. J Am Chem Soc 2009, 131: 10107–10112. 10.1021/ja9018012

Basu B, Bhuiyan MMH, Das P, Hossain I: Catalytic transfer reduction of conjugated alkenes and an imine using polymer-supported formates. Tetrahedron Lett 2003, 44: 8931–8934. 10.1016/j.tetlet.2003.10.019

Dar MA, Nam SH, Youn SK, Kim WB: Synthesis, characterization, and electrochemical properties of self-assembled leaf-like CuO nanostructures. J Solid State Electrochem 2010, 14: 1719–1726. 10.1007/s10008-010-1022-z

Bahrami K, Khodaei MM, Nejati A: Synthesis of 1,2-disubstituted benzimidazoles, 2-substituted benzimidazoles and 2-substituted benzothiazoles in SDS micelles. Green Chem 2010, 12: 1237–1241. 10.1039/c000047g

Jammi S, Barua P, Rout L, Saha P, Punniyamurthy T: Efficient ligand-free nickel-catalyzed C–S cross-coupling of thiols with aryl iodides. Tetrahedron Lett 2008, 49: 1484–1487. 10.1016/j.tetlet.2007.12.118

Cramer CJ, Truhlar DG ACS (eds) (1994) Structure and Reactivity in Aqueous Solution. Washington, DC

Sharma G, Kumar R, Chakraborti AK: ‘On water’ synthesis of 2,4-diaryl-2,3-dihydro-1,5-benzothiazepines catalysed by sodium dodecyl sulfate (SDS). Tetrahedron Lett 2008, 49: 4269–4271. 10.1016/j.tetlet.2008.04.146

Kumar D, Seth K, Kommi DN, Bhagat S, Chakraborti AK: Surfactant micelles as microreactors for the synthesis of quinoxalines in water: scope and limitations of surfactant catalysis. RSC Adv 2013, 3: 15157–15168. 10.1039/c3ra41038b

Seth K, Roy SR, Pipaliya BV, Chakraborti AK: Synergistic dual activation catalysis by palladium nanoparticles for epoxide ring opening with phenols. Chem Commun 2013, 49: 5886–5888. and references cited therein 10.1039/c3cc42507j

Jana S, Dutta B, Bera R, Koner S: Immobilization of palladium in mesoporous silica matrix: preparation, characterization, and its catalytic efficacy in carbon-carbon coupling reactions. Inorg Chem 2008, 47: 5512–5520. 10.1021/ic8004294

Ma D, Geng Q, Zhang H, Jiang Y: Assembly of substituted phenothiazines by a sequentially controlled CuI/l-proline-catalyzed cascade C–S and C–N bond formation. Angew Chem Int Ed 2010, 49: 1291–1294. 10.1002/anie.200905646

Acknowledgements

We thank DST, New Delhi, for financial support [Grant No. SR/S1/OC– 86/2010 (G)], and DS thanks CSIR, New Delhi, for awarding research fellowship. We thank Dr. G. De, CSIR-CGCRI, Kolkata for Powder XRD measurements and Prof. A. K. Nandy, I.A.C.S., Kolkata for HRTEM analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

DS carried out the whole work and drafted the manuscript. BB conceived the study, followed the development, and finalized the manuscript. Both authors read and approved the final manuscript.

Electronic supplementary material

13588_2014_17_MOESM1_ESM.pdf

Additional file 1: Supporting data. 1H and 13C NMR spectral data for sulfanes and scanned spectra and a comparative 1H-NMR spectra of Phenothiazine. (PDF 552 KB)

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sengupta, D., Basu, B. An efficient heterogeneous catalyst (CuO@ARF) for on-water C-S coupling reaction: an application to the synthesis of phenothiazine structural scaffold. Org Med Chem Lett 4, 17 (2014). https://doi.org/10.1186/s13588-014-0017-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13588-014-0017-7