Abstract

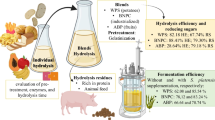

A total of 398 kt of pasta waste (PW), generated during the production process of pasta, were produced in 2021. Due to its chemical composition and practically zero cost, PW has already been studied as a raw material for the production of lactic acid (LA) through fermentations. The main objective of this article was to improve the economic viability of the process by replacing commercial enzymes, necessary for starch hydrolysis in PW, with raw enzymes also produced from wastes. Enzyme synthesis was achieved through solid-state fermentation (SsF) of wheat bran by Aspergillus awamori or Aspergillus oryzae at various moisture contents. The maximum amylase activity (52 U/g dry solid) was achieved after 2 days of fermentation with A. awamori at 60% of moisture content. After that, the enzymes were used to hydrolyse PW, reaching 76 g/L of total sugars, 65 g/L of glucose and a yield of 0.72 gglu/gds with the enzymes produced by A. awamori. Subsequently, the hydrolysate was fermented into LA using Bacillus coagulans A559, yielding 52 g/L and 49 g/L with and without yeast extract, respectively. Remarkably, compared to the process with commercial enzymes, a higher LA yield was reached when enzymes produced by SsF were added (0.80 gLA/gglu). Furthermore, the productivities between the two processes were similar (around 3.9 g/L/h) which highlights that yeast extract is not necessary when using enzymes produced by SsF.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Introduction

The reduction of food waste has become an important target of the European Commission by promoting a system for sustainable food production [1]. One of the main objectives is building a system in which food losses at the production stage, where 30% of the total food waste is generated, are limited. Wastes from the food production stage can be used as raw materials to obtain value-added products following environmentally friendly processes. As residues, they are low-cost materials and do not compete with the food chain. Additional advantages of using this type of waste are that they have a homogeneous composition, a high concentration of carbohydrates and are produced in large quantities [2].

Pasta is massively consumed all over the world, with a total of 16.9 Mt produced in 2021 [3]. In the same year, the country with the highest consumption of pasta was Italy, where 23.5 kg of pasta was consumed per person per year [3]. However, the production of such amount of pasta also generates an important amount of food waste. In the study performed by Principato et al., food losses and wastes were estimated in 1979 g per kg of pasta manufactured [4]. Nearly 1.2% of this food losses and wastes were pasta wastes obtained during the production process (PW). This implies that around 398 kt of PW were generated in the whole world in 2021.

The valorisation of this residue, PW, can be performed via a sequential hydrolysis and fermentation process. The high starch content (60% w/w) of PW means that it can be enzymatically hydrolysed by the addition of amylases in a process which requires low energy consumption and that runs under mild and non-corrosive conditions [5]. However, a downside of the hydrolysis is that it requires expensive enzymes produced mainly from pure sugars. It is well known that the use of such costly enzymes increases the costs of the processes and hinders their implementation at an industrial scale. Alternatively, enzymes can be produced by fermentation of agricultural wastes. Many studies are available in the literature where enzymes produced via solid-state fermentation (SsF) were successfully employed in the hydrolysis of organic wastes such as sugarcane bagasse [6], sugar beet pulp [7], waste bread [8], organic fraction of municipal solid waste (OFMSW) [9, 10], etc.

SsF is a process where microorganism grows in an environment without free water [11]. A solid material is used in these fermentations that could be used as nutrient source or as supporting material infused with nutrients essential for microbial growth [12]. SsF is standard and steady developing bioprocess to produce enzymes [13]. The production of amylases by SsF has been investigated on different industrial wastes, nonetheless, it has been consistently reported that wheat bran (WB) is one of the best substrates to produce amylases in SsF by Aspergillus species [14]. Furthermore, Kunamneni et al. tested several substrates for the production of this enzyme with Thermomyces lanuginosus, founding that WB was also the one that produce higher enzyme activity [15].

Lactic acid (LA) is a valuable platform chemical with wide-ranging applications [16]. It is commonly used in the food, pharmaceutical, cosmetic, and textile industries [17]. For instance, it is used as preservative and pH adjusting agent in the food industry. Recently, LA has also gained interest as a precursor of biodegradable polymer (PLA). Due to the wide variety of applications, the market value of LA raised to 2.7 billion dollars in 2020 and is predicted to grow at an annual rate of 8.0% from 2021 to 2028 [16]. Although LA can be produced via chemical processes, the fermentative one is preferred because it produces pure optical enantiomers. However, in most cases the fermentation media require the supplementation of nutrients to reach higher yields and good microbial growth. Many studies supplement the medium with yeast extract (YE), which raises costs. This is a significant drawback when the process is to be implemented on an industrial scale [18].

In this article, the enzyme production by solid-state fermentation was incorporated to the lactic acid production process from pasta waste following a biorefinery approach. The main objective of this research was to improve the production process of LA from PW, making the process more economically viable. To achieve it, the addition of enzymes produced by SsF was evaluated as a substitute of the commercial enzymatic cocktail. As previously stated, the enzymes cost is the main bottleneck of the enzymatic hydrolysis process. WB was selected as the best raw material, based on the literature, for amylase production under SsF, and two fungi (Aspergillus awamori and Aspergillus oryzae) were studied at various moisture contents and fermentation times. Finally, LA production was compared on the different hydrolysates produced, testing also the supplementation of YE in the fermentation. Additionally, the price of LA was calculated based only on the enzymes and supplements studied in order to see the economical differences between the different methodologies applied.

Materials and methods

Substrate

WB was used in SsF to produce enzymes. The material was provided by a farm (SC ALBATROS SRL) in Romania and was kept at – 25 °C until use. Prior to SsF, the required amount of WB for SsF was sterilised at 121 °C for 15 min.

PW was used as the substrate during the enzymatic hydrolysis to produce sugars. It was provided as lasagne sheets of different sizes from a company in Belgium. The composition of PW was analysed in our previous work [19]. To have a homogeneous substrate at the desired concentration of PW, it was firstly mixed with a small amount of distilled water into a mixer. After that, water was added to achieve the desired PW concentration. Finally, the substrate was inactivated just before the hydrolysis by heating the medium up to 80 °C for 30 min inside the reactor [19].

Microorganisms

Two fungal strains were used in the SsF of WB: Aspergillus awamori (DSM 63272) and Aspergillus oryzae (DSM 1862). All the strains were stored at − 80 °C and were reactivated in potato dextrose medium at 30 °C for 5 days. After that, the spores collected from the liquid medium were seeded in Petri dishes with potato dextrose agar and incubated at 30 °C for 5 days. Then, the spores were collected with a solution of NaCl (0.9% w/v) and the concentration of spores was calculated using a Thoma cell counting chamber.

Bacillus coagulans A559 was used in LA fermentations. This strain belongs to the strain library of the Microbiome Biotechnology Department of the Leibniz Institute for Agricultural Engineering and Bioeconomy (Potsdam, Germany). The strain was stored at – 80 °C and was reactivated in MRS broth at 52 °C. Then, the strain was grown in MRS agar slants at 52 °C. After that, the whole content of the slant was transferred into an Erlenmeyer flask with 60 mL of MRS. To stabilise the pH during the growth of the microorganism, the MRS medium was supplemented with 0.7 g EVERZIT® Dol 0.5–2.5 mm (Evers, Germany), composed mainly of CaCO3 (68%), MgO (25%), CaO (1%) and MgCO3 (5.6%). The flask was incubated at 40 °C and 100 rpm for 16 h.

Solid-state fermentation of wheat bran

The SsF of WB was performed in 300-mL Erlenmeyer flasks. The sterile solids [10 g of dry solid (gds)] were added to the flask and the moisture content was adjusted to 60, 70 or 80% w/w by the addition of sterile distilled water. Also, the required volume of a spore suspension to have a concentration of 1·107 spores per gramme of solid was added to the flask. The flasks were closed with a cotton plug and incubated in static conditions at 30 °C for 7 days. The SsF was performed in duplicate and, every 24 h, the whole content of the two flasks were collected for sample analysis.

Enzyme extraction

After the SsF, enzymes were extracted by the addition of a Tween 80 solution (0.1% w/v) in a solid-to-liquid ratio of 1:8 to the Erlenmeyer flask. The flasks were placed in an incubator at room temperature for 30 min at 150 rpm. After that, the mixture was centrifuged at 5000g for 15 min at 7 °C to separate the solids. The supernatant was collected and stored until further analysis.

Enzymatic hydrolysis of pasta waste

The enzymatic hydrolysis of PW was carried out with commercial enzymes and with the enzymes produced by SsF. For the first case, the commercial enzyme cocktail Stargen™ 002 was used, adding 1.28 μL/gdpw (grammes of dry PW) at the beginning of the hydrolysis. For the second case, fermented WB obtained after the SsF by A. awamori or A. oryzae was added at the beginning of the hydrolysis as a source of enzymes. The SsF with the fungus A. awamori was performed at 60% of moisture content and the solids, containing the raw enzymes, were collected after 3 days. In the fermentation with A. oryzae, the SsF was carried out at 70% of moisture content and the solids, containing the raw enzymes, were collected 2 days of fermentation. In both cases, SsF was performed with 10 gds of WB in a 300-mL Erlenmeyer flask closed with cotton, incubating the flask at 30 °C. Immediately after SsF, the entire flask contents were added to the reactor to start the enzymatic hydrolysis of PW.

The hydrolysis was carried out in a 2-L reactor with a working volume of 1 L. The temperature and the stirrer speed were set at 50 °C and 300 rpm, respectively. Before the hydrolysis, the empty reactor was autoclaved at 121 °C for 15 min. After that, 200 g of PW were blended with 1 L of distilled water and were added to the reactor. Then, the reactor (containing the PW) was heated up to 80 °C for 30 min to inactivate the media [19]. After that, the media was cooled down until 50 °C. Afterwards, the pH was adjusted to 5 at the beginning of the hydrolysis, but was not regulated after that. Finally, enzymes were added to the reactor to start the enzymatic hydrolysis.

Samples were withdrawn periodically, inactivated at 95 °C for 20 min and kept at − 20 °C until further analysis. The enzymatic hydrolysis was performed in duplicate. Hydrolysis yields were calculated as the mass of sugars obtained (glucose or total sugars) divided by the initial mass of dry solids (gglu/gds or gTS/gds), considering the initial dry weight of PW and WB when fermented WB was added to the hydrolysis as enzyme source.

Lactic acid fermentation of pasta waste hydrolysate

After the enzymatic hydrolysis, the hydrolysate was centrifuged (5000g—15 min) and the supernatant was fermented to LA with the strain Bacillus coagulans A559. The fermentations were carried out at 52 °C and 200 rpm in an Eloferm multifermentation system (Biotronix GmbH, Germany) with 300 mL working volume. The bioreactors were inoculated with 5% v/v of the preculture grown as detailed in Section “Microorganisms” and the pH was controlled at 6.0 with a NaOH solution (20% w/v).

Samples were withdrawn periodically, inactivated at 95 °C for 20 min and kept at − 20 °C until further analysis of sugars and LA. The LA fermentation was performed in duplicate.

Enzymatic hydrolysis and lactic acid fermentation at pilot scale

LA production was studied at the pilot scale through sequential hydrolysis and fermentation in a 72-L BIOSTAT UD bioreactor (B-Braun Biotech, Germany) with a working volume of 50 L. PW (200 g/L) were added into the reactor and heated up at 80 °C for 30 min to inactivate the media [19]. After that, the temperature and the agitation of the bioreactor were set to 50 °C and 200 rpm, respectively. Then enzymes, at a concentration of 1.28 µL/gdpw were added. After 24 h of hydrolysis, the bioreactor settings were configured to perform the LA fermentation. Thus, temperature was adjusted to 52 °C, pH was raised to 6, and the hydrolysate was supplemented with 5 g/L of yeast extract. The inoculum (A559) for the fermentation was prepared as described in Section “Microorganisms” (MRS medium) in a 2-L BIOSTAT bioreactor (Sartorius AG, Germany). During the fermentation, the pH was maintained at 6 by the addition of NaOH (20% v/v). Samples were taken regularly, inactivated at 95 °C for 20 min and kept at − 20 °C until further analysis.

The main objective of this study was to evaluate if the removal of solids prior the fermentation could improve our previous results by reducing the lag phase of the experiments. Therefore, another experiment was performed with the same conditions, but the hydrolysate was microfiltrated before the LA fermentation.

Analytics

Moisture content

The moisture content was measured during the SsF. Samples (1 g) were taken before the enzyme extraction. The samples were weight in a ceramic cup and dried in an oven at 105 °C for 24 h. The moisture content was determined as the difference on weight between the wet and dried samples divided by the weight of wet sample.

Determination of sugars and organic acid concentration

Glucose, fructose, xylose, arabinose, LA and acetic acid were quantified by high-performance liquid chromatography (HPLC). HPLC was carried out with a Eurokat H column (300 mm × 8 mm × 10 µm; Knauer, Berlin, Germany) and a refractive index detector RI-71 (SHODEX, Tokyo, Japan). The mobile phase had a flowrate of 0.8 mL/min of 5 mM H2SO4 and the injection volume was 10 µL. LA L-/D-isomer ratio was measured by HPLC (Chiralpak®MA( +) column (50 mm × 4.6 mm × 3 µm; DAICEL, Tokyo, Japan) with a 2 mM CuSO4 mobile phase and an UV detector.

Enzyme activity determination

Amylase activity was measured by mixing 0.5 mL of potato starch suspension (1.0% w/v in distilled water, pH 6.0) with 0.5 mL of crude enzyme extract. The mixture was incubated at 60 °C for 10 min in a water bath. Afterwards, 1 mL of 3,5-dinitrosalicylic acid (DNS) was added to stop the reaction.

After the enzyme reaction, the concentration of reducing sugars produced was determined by the DNS method. For that, the tubes containing the samples and the DNS reagent were boiled for 10 min, and then cooled down in ice water to stop the reaction. Distilled water (8 mL) was added to the tubes and the absorbance was measured at 540 nm.

The enzyme activity of each enzyme was expressed as micromole of glucose obtained per minute at the tested conditions. The assays were performed in duplicate, and the results were expressed as the average value and the standard deviation.

Economic evaluation of lactic acid production

The production cost of lactic acid was estimated with the aim of comparing the different processes tested in this research. Even though an exhaustive estimation should be performed considering the additional equipment required for the SsF stage, a basic estimation was performed to show the influence of the enzyme cocktail and nutrient supplementation on the lactic acid price. Thus, the calculation is based on the amount of the commercial enzyme Stargen™ 002, the wheat bran or the yeast extract required to produce 1 kg of LA according to the yields obtained in each condition tested. The unit price of each component was extracted from the recent literature: enzyme Stargen™ 002 (9.26 €/kg [20]), wheat bran (0.15 €/kg [21]) and yeast extract (25.5 €/kg [22]).

Results and discussion

In our previous study, PW was evaluated for LA production via enzymatic hydrolysis, with commercial enzymes, and submerged liquid fermentation [19]. In that work, various enzyme activities were tested for the hydrolysis of PW, and different Bacillus coagulans strains were screened for LA production. The separate hydrolysis and fermentation were scaled up to 50 L, reaching a yield of 0.67 gLA/gdPW.

Although good yields were previously obtained using commercial enzymes for the hydrolysis of PW, their high cost made difficult the work at the pilot scale and hindered the commercialisation of the process [23]. In fact, several authors have stated that the high cost of enzymes is a major bottleneck in the development of biorefineries based on organic wastes [24, 25]. Thus, many investigations have been carried out to produce enzymes via SsF from low-cost materials, such as agro-industrial wastes or subproducts, [26, 27]. In this work, WB was used to produce enzymes via SsF, which were then used for the hydrolysis of PW. Finally, PW hydrolysates were fermented and the results were compared to those of the process that utilised commercial enzymes for the hydrolysis.

Enzyme production by solid-state fermentation of wheat bran

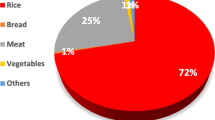

PW is mainly composed of carbohydrates, being the main component (80% w/w aprox. [28]) starch, a polymer of glucose units joined by glycosidic bonds. Therefore, PW is an interesting raw material to produce sugars by enzymatic hydrolysis, using amylase as the main enzyme. The production of amylase by SsF has been studied on several raw materials such as WB, dried potato peel, dried fruit waste, rice bran, groundnut cake, coconut cake, soybean powder, bagasse, paddy husk, to name a few [29, 30]. However, WB has shown the highest yield on amylase activity [29, 30]. Amongst others, one of the main factors influencing enzyme production is the microorganism used to ferment the solid. In this sense, two fungus strains were tested as amylase producers, Aspergillus awamori and Aspergillus oryzae. Moreover, the enzyme production was optimised by studying different fermentation times of the solid and three moisture content (60, 70 and 80%) as they are parameters with high impact on the enzyme production by SsF.

The amylase production at various moisture contents with both fungi showed different trends, as shown in Fig. 1. In the fermentation carried out with A. awamori (Fig. 1a), the enzyme activity increased during the first 2 days and then, it decreased until reaching a stable value of 29.79 ± 1.93 U/gds. Also, from the moisture contents tested, the enzyme activity increased as the moisture content decrease from 80 to 60%. Finally, the maximum amylase activity of 52.21 ± 0.04 U/gds was reached after 2 days of fermentation at 60% of moisture content. On the other hand, the moisture content which yielded the highest enzyme activity in the fermentation performed with A. oryzae (Fig. 1b) was 70%. In this case, over the firsts 3 days of fermentation, enzyme production rate differed amongst the moisture contents tested, nonetheless, they reached a similar value (31.81 ± 1.97 U/gds) between the fourth and fifth day of fermentation. After that, an increase on the enzyme activity was observed in fermentations with an initial moisture content of 60% or 70%, reaching a value of 50.04 ± 0.07 U/gds after 7 days of fermentation.

The amylase activity obtained in this article is comparable to other studies found in the literature. Many studies can be found in which amylase is produced by SsF of WB with different microorganisms, ranging from 48 to 9421 U/g [21]. This wide difference is due to the use of different microorganism species and the establishment of diverse fermentation conditions such as the addition of mineral salts to the fermentation medium. For instance, Tanasković et al. produced the maximum amylase activity of 107 U/g on the 7th day of fermentation by using Bacillus sp. TMF-2, a strain isolated from dairy product (Collection of cultures of the Faculty of Technology and Metallurgy, University of Belgrade) [11]. However, Kalia et al. obtained 192 U/g of α-amylase with the fungus Trichoderma reesei when WB was supplemented with salt media containing NaNO3 (2 g/L), K2HPO4 (1 g/L), MgSO4·7H2O, (0.5 g/L), KCl (0.5 g/L), yeast extract (2.5 g/L) [29].

According to Kunamneni et al., the moisture content in the SsF has a great influence on the production of enzymes and their secretion into the medium as it interferes with the physical properties of the particles [15]. During the performance of the experiments reported in this article, variations on microbial growth could be observed as a result of the differences in the initial moisture content of the solids (Fig. 2). At a moisture content of 80%, the porosity of the solid was reduced and the inter-particle space was filled with water instead of air, limiting the oxygen transfer. As a result, growth was more evident on the surface of the solid particles, as seen in Fig. 2, where there is no growth on the flask walls that are in contact with the solids at 80% moisture content. However, both fungi showed uniform growth throughout the bed of solids at moisture contents of 60 and 70% (Fig. 2). Most likely, the negative effect of excess water on the growth of the microorganism was the cause for the lower enzyme activities observed at 80% moisture content.

Image of A. oryzae before SSF at 60%, 70% and 80% moisture content (a), and after 3 days of SSF (b) at 60% (c), 70% (d) and 80% (e) moisture content. Image of A. awamori before SSF at 60%, 70% and 80% moisture content (f), and after 3 days of SSF (g) at 60% (h), 70% (i) and 80% (j) moisture content. Images from c, d, e, h, i, j shows the bottom of the flask

Enzymatic hydrolysis of pasta waste

PW was hydrolysed with the enzymes produced by SsF. The profile for the sugars produced during the enzymatic hydrolysis of PW is shown in Fig. 3. The hydrolysis of PW by the addition of the fermented WB by A. awamori (10 gds) produced 76.65 ± 2.59 g/L of total sugar in 48 h, 65.12 ± 2.53 g/L of which were glucose (Fig. 3a). In this way, a hydrolysis yield of 0.72 gglu/gds was achieved. On the other hand, the hydrolysis of PW with the addition of the fermented WB by A. oryzae (10 gds) produced 64.84 ± 0.99 g/L of total sugars in 48 h, 39.68 ± 0.66 g/L of which were glucose (Fig. 3b). In this case, the hydrolysis yield only was 0.44 gglu/gds.

The differences found in the amount of glucose produced are related to the concentration of disaccharides produced. For the first case (Fig. 3a), the concentration of disaccharides increased until 10.51 ± 0.26 g/L and then decreased to 7.96 ± 0.22 g/L. However, for the second case (Fig. 3b), the concentration of disaccharides reached 30.46 ± 0.43 g/L and then decreased to 22.76 ± 0.08 g/L. Such difference could be the result of a lack of an enzyme able to hydrolyse maltose produced during the hydrolysis of starch. According to the literature, the hydrolysis of starch is achieved by the synergistic action of three types of amylases: α-amylase (EC 3.2.1.1), β-amylase (EC 3.2.1.2) and γ-amylase (EC 3.2.1.3) [31]. The differences between them lie on the type of bond they hydrolyse. α-amylase is an endo-enzyme that cleaves the α-(1,4)-glycosidic linkages of amylose, releasing maltotriose and maltose, and after cleavage of α-(1,6)-glycosidic bonds of amylopectin, it releases glucose [32]. β-Amylase is an exo-enzyme that hydrolyses α-(1,4)-glycosidic bonds from the non-reducing end of the polysaccharide chain, producing maltose units [32]. γ-Amylase is an enzyme that cleaves the last α-(1,4)-glycosidic bond at the non-reducing end as well as the α-(1,6)-glycosidic linkages of the amylose and amylopectin polymers, producing glucose [32]. According to Sahnoun et al., they identified three different amylases produced by A. oryzae (S2) under SsF. One of them was only produced on the SsF and hydrolysed starch to maltose, maltotriose, and other maltooligosaccharides of higher polymerisation degrees, while the others two amylases were also secreted on submerged fermentation [33]. Knowing this, it seems that amylases produced by A. oryzae had a bigger proportion of β-amylase due to the high content of maltose on the hydrolysate which was not further hydrolysed to glucose. Meanwhile, the amylase produced by A. awamori could have a higher proportion of α-amylase or γ-amylase.

Lactic acid fermentation of pasta waste hydrolysates obtained with commercial enzymes

In a prior report [19], PW hydrolysates were used in LA fermentations, however, the processes showed a longer lag phase when the experiments were performed at the pilot scale. It is known that remaining solid particles after the hydrolysis can affect fermentation performance [19]. Thus, in this work, solid particles were removed from the medium after hydrolysis by microfiltration before the fermentation, the results are shown in Fig. 4.

Evolution of the concentrations of total sugars (red lines) and LA (blue lines) during the enzymatic hydrolysis and lactic fermentation of PW: without solid removal (red filled square, blue filled diamond) and with solid removal (red square, blue diamond). Inoculation time is shown with a line at 24 h

Sugar production during the enzymatic hydrolysis of PW was very fast, finishing in almost 24 h with a total sugar concentration of 67 g/L. After that, the strain Bacillus coagulans A559 was inoculated to produce LA. The effect of the solids removal was evident, with a clear reduction of the fermentation lag phase. In fact, there was a very short lag phase (2 h) in comparison to the fermentation without solids removal which lasted almost 14 h. Although both experiments reached similar LA concentrations (around 47 g/L) and yields (about 0.65 gLA/gds), productivities differed significantly. A productivity of 1.56 g/L/h was reached when solids were removed from the media while 0.97 g/L/h was attained in the other case, showing a difference of 20 h between both conditions. Due to these results, the solids in the hydrolysates obtained with the enzymes produced by SsF were also removed before the fermentations.

Lactic acid fermentation of pasta waste hydrolysates obtained with the enzymes from solid-state fermentation

Both hydrolysates obtained with the enzymes produced by SsF were used as media for LA production (Fig. 5). In these fermentations, the supplementation of the hydrolysate with yeast extract (5 g/L) was tested. Nevertheless, a very similar trend was observed when fermentations were carried out with and without yeast extract supplementation. This result was highly relevant given that the addition of yeast extract has a large impact on the total cost of the process. Yeast extract is expensive and many authors have searched for alternatives to substitute yeast extract for a low-cost supplement [34,35,36]. In our case, the addition of fungal fermented solids into the enzymatic hydrolysis seemed to provide some nutrients, being unnecessary to add other nitrogen supplementation during the fermentation.

LA fermentation of the hydrolysate obtained with the enzymes produced by A. awamori (a) and A. oryzae (b): supplemented with yeast extract (glucose (blue circle), total sugars (blue triangle) and LA (blue square)) and without supplementation (glucose (red circle), total sugars (red triangle) and LA (red square))

The highest LA concentration was achieved with the hydrolysate produced with the enzymes from A. awamori. This was expected since the glucose concentration was higher in that hydrolysate. By the end of the fermentation, the concentration of LA obtained on the hydrolysates produced with the enzymes from A. awamori and A. oryzae were 52 g/L and 41 g/L in the fermentation with yeast extract, and 49 g/L and 38 g/L in the fermentation without yeast extract, respectively. In all cases studied, the optical purity of lactic acid was determined higher than 99% of L-lactic acid.

Some recent studies on the production of LA from agricultural or food wastes are summarised in Table 1. Between the selected studies, the maximum LA yield and productivity were attained via the continuous fermentation of rice straw. However, the yields achieved in this study were comparable to the one for corn stover and were higher than the ones for the organic fraction of municipal solid waste (OFMSW) and sugar beet pulp. Additionally, the productivity was higher on the present study, except for the continuous fermentation.

Comparison of both methodologies for lactic acid production

Both processes studied for LA production, with commercial enzymes and with enzymes produced by SsF, were evaluated based on LA productivity and yields estimated from the enzymatic hydrolysis and the LA fermentation steps (Table 2). Considering the enzymatic hydrolysis step, similar yields (Y gglu/gds) were reached when fermented WB by A. awamori and the commercial enzyme cocktail Stargen™ 002 were used to hydrolyse PW (0.72 and 0.79 gglu/gds). However, a lower yield was obtained when fermented WB by A. oryzae was added (0.44 gglu/gds). Nevertheless, the yields of total sugars from dry solids (Y gTS/gds) were higher when the enzymes produced by SsF were used, reaching 0.85, 0.72 and 0.82 gTS/gds with the enzymes produced by A. awamori, A. oryzae, and with Stargen™ 002, respectively. It is important to note that the yields obtained in the hydrolysis carried out with the fermented solid contained, in addition to PW, 10 gds/L of WB, which can be hydrolysed with the enzymes produced during SsF. Moreover, the difference found between A. awamori’s enzymes and the commercial one could be the result from the production of a wide and more robust variety of enzymes. Several authors have reported the production of cellulases, xylanases or pectinases by A. awamori on SsF [27, 41], which may hydrolyse the non-starch material of PW. Likewise, the differences between A. oryzae’s enzymes and the others were the result of the non-complete hydrolysis of maltose to glucose.

Regarding the LA fermentation step (Table 2), the highest yield of LA from glucose (Y gLA/gglu) and from dry solids (Y gLA/gds) were achieved with the hydrolysate obtained with the enzymes produced by A. awamori supplemented with yeast extract (0.80 gLA/gglu and 0.58 gLA/gds). Moreover, a similar yield (0.75 gLA/gglu) was obtained in the experiment using commercial enzymes supplemented with YE and in the experiment using the enzymes from A. awamori without YE supplementation. Thus, the same amount of LA obtained in experiments with the addition of a commercial enzyme cocktail and yeast extract can be obtained using only the enzymes produced by A. awamori in SsF. The same effect was observed regarding LA productivity, the highest productivity was achieved with the enzymes from A. awamori supplemented with YE, while a similar productivity was reached between the crude enzymes without YE supplementation and the commercial enzymes with YE supplementation.

Besides the high yield attained, the production cost of LA is also important in the economic viability of the process at industrial scale. For this reason, the production cost was estimated based on the cost of WB, enzymes and yeast extract supplements. Although an exhaustive economic study should be required to confirm the viability of the process, some differences were observed taking in consideration only these factors. The cost of the enzymes and supplements to produce 1 kg of LA according to the process followed are summarised in Table 3. As clearly seen, the addition of YE and the commercial enzymes are the factors with a higher impact on the final cost of LA. Therefore, the production of lactic with the commercial enzyme Stargen™ 002 and with the YE supplementation was 12 times higher than the one with only the addition of fermented WB by A. awamori.

Conclusions

The commercial enzyme cocktail Stargen™ 002, used to hydrolyse PW, was successfully replaced by enzymes produced via SsF. A. awamori yielded the highest amylase activity after SsF of WB for two days at 60% of moisture content. Also, higher yields were obtained during the enzymatic hydrolysis of PW when these enzymes were added. Regarding LA production, similar yields were reached between the hydrolysate obtained after the addition of the fermented WB by A. awamori and the one produced with commercial enzymes and supplemented with YE. To conclude, the production of LA from PW was improved by the addition of enzymes produced through solid-state fermentation, with no addition of yeast extract during lactic fermentation.

Availability of data and materials

Not applicable.

Abbreviations

- BE:

-

Beef extract

- Conc:

-

Concentration

- CWP:

-

Cheese whey powder

- DNS:

-

3,5-Dinitrosalicylic acid

- glu:

-

Glucose

- ds:

-

Grammes of dry solid

- dPW:

-

Dry pasta waste

- LA:

-

Lactic acid

- MICF:

-

Membrane integrated continuous fermentation

- OFMSW:

-

Organic fraction of municipal solid waste

- P:

-

Productivity

- PEP:

-

Peptone

- PW:

-

Pasta waste

- SHF:

-

Separate hydrolysis and fermentation

- SSCF:

-

Simultaneous saccharification and fermentation

- SsF:

-

Solid-state fermentation

- TS:

-

Total sugars

- VB:

-

Vitamins B

- WB:

-

Wheat bran

- w/o:

-

Without supplementation

- Y:

-

Yield

- YE:

-

Yeast extract

References

European Commission. EU Platform on food losses and food waste. Activity report—first mandate (2016–2021). 2021. https://food.ec.europa.eu/system/files/2022-02/fw_lib_stud-rep-pol_flw_act-report_2021.pdf. Accessed 8 July 2022.

Albizzati PF, Tonini D, Astrup TF. A quantitative sustainability assessment of food waste management in the European Union. Environ Sci Technol. 2021;55:16099–109.

International Pasta Organisation. Int. Pasta Organ. 2021. https://internationalpasta.org/annual-report/. Accessed 9 July 2022.

Principato L, Ruini L, Guidi M, Secondi L. Adopting the circular economy approach on food loss and waste: the case of Italian pasta production. Resour Conserv Recycl. 2019;144:82–9.

Saini JK, Himanshu, Hemansi, Kaur A, Mathur A. Strategies to enhance enzymatic hydrolysis of lignocellulosic biomass for biorefinery applications: a review. Bioresour Technol. 2022;360:127517.

Pirota R, Delabona P, Farinas C. Enzymatic hydrolysis of sugarcane bagasse using enzyme extract and whole solid-state fermentation medium of two newly isolated strains of aspergillus oryzae. Chem Eng Trans. 2014;38:259–64.

Marzo C, Díaz AB, Caro I, Blandino A. Conversion of exhausted sugar beet pulp into fermentable sugars from a biorefinery approach. Foods. 2020;9:1351.

Leung CCJ, Cheung ASY, Zhang AY-Z, Lam KF, Lin CSK. Utilisation of waste bread for fermentative succinic acid production. Biochem Eng J. 2012;65:10–5.

Ladakis D, Stylianou E, Ioannidou S-M, Koutinas A, Pateraki C. Biorefinery development, techno-economic evaluation and environmental impact analysis for the conversion of the organic fraction of municipal solid waste into succinic acid and value-added fractions. Bioresour Technol. 2022;354: 127172.

Martău G-A, Unger P, Schneider R, Venus J, Vodnar DC, López-Gómez JP. Integration of solid state and submerged fermentations for the valorization of organic municipal solid waste. J Fungi. 2021;7:766.

Tanasković SJ, Šekuljica N, Jovanović J, Gazikalović I, Grbavčić S, Đorđević N, et al. Upgrading of valuable food component contents and anti-nutritional factors depletion by solid-state fermentation: a way to valorize wheat bran for nutrition. J Cereal Sci. 2021;99: 103159.

Kumar V, Ahluwalia V, Saran S, Kumar J, Patel AK, Singhania RR. Recent developments on solid-state fermentation for production of microbial secondary metabolites: challenges and solutions. Bioresour Technol. 2021;323: 124566.

Leite P, Sousa D, Fernandes H, Ferreira M, Costa AR, Filipe D, et al. Recent advances in production of lignocellulolytic enzymes by solid-state fermentation of agro-industrial wastes. Curr Opin Green Sustain Chem. 2021;27: 100407.

Premalatha A, Vijayalakshmi K, Shanmugavel M, Rajakumar GS. Optimization of culture conditions for enhanced production of extracellular α-amylase using solid-state and submerged fermentation from Aspergillus tamarii MTCC5152. Biotechnol Appl Biochem. 2022. https://doi.org/10.1002/bab.2403.

Kunamneni A, Permaul K, Singh S. Amylase production in solid state fermentation by the thermophilic fungus Thermomyces lanuginosus. J Biosci Bioeng Elsevier. 2005;100:168–71.

Chenebault C, Moscoviz R, Trably E, Escudié R, Percheron B. Lactic acid production from food waste using a microbial consortium: focus on key parameters for process upscaling and fermentation residues valorization. Bioresour Technol. 2022;354: 127230.

Yadav P, Chauhan AK, Singh RB, Khan S, Halabi G. Chapter 22—organic acids: microbial sources, production, and applications. In: Singh RB, Watanabe S, Isaza AA, editors. Functional foods and nutraceuticals in metabolic and non-communicable diseases. Cambridge: Academic Press; 2022. p. 325–37.

Johnson M, Burgess N, Shi S, Li J, Blersch D. Formulation of fish waste as a low-cost fermentative nutrient for lactic acid production by Lactobacillus pentosus. Waste Biomass Valor. 2022;13:2917–25.

López-Gómez JP, Unger P, Schneider R, Pierrard M-A, Venus J. Upgrading pasta wastes through lactic acid fermentations. Food Bioprod Process. 2022;135:135–42.

Weber CT, Trierweiler LF, Casagrande T, Trierweiler JO. Economic evaluation of sweet potato distilled beverage produced by alternative route. Int J Dev Sustain. 2018;7:14.

Papadaki E, Kontogiannopoulos KN, Assimopoulou AN, Mantzouridou FTh. Feasibility of multi-hydrolytic enzymes production from optimized grape pomace residues and wheat bran mixture using Aspergillus niger in an integrated citric acid-enzymes production process. Bioresour Technol. 2020;309: 123317.

Ju J-H, Ko D-J, Heo S-Y, Lee J-J, Kim Y-M, Lee B-S, et al. Regulation of lipid accumulation using nitrogen for microalgae lipid production in Schizochytrium sp. ABC101. Renew Energy. 2020;153:580–7.

Zhang H, Han L, Dong H. An insight to pretreatment, enzyme adsorption and enzymatic hydrolysis of lignocellulosic biomass: experimental and modeling studies. Renew Sustain Energy Rev. 2021;140: 110758.

Patel AK, Singhania RR, Sim SJ, Pandey A. Thermostable cellulases: current status and perspectives. Bioresour Technol. 2019;279:385–92.

Siqueira JGW, Rodrigues C, de Vandenberghe LPS, Woiciechowski AL, Soccol CR. Current advances in on-site cellulase production and application on lignocellulosic biomass conversion to biofuels: a review. Biomass Bioenergy. 2020;132:105419.

dos Santos Costa R, de Almeida SS, d’Avila CCE, Freire DMG, Moura-Nunes N, Monteiro M, et al. Enzymes produced by solid state fermentation of agro-industrial by-products release ferulic acid in bioprocessed whole-wheat breads. Food Res Int. 2021;140:109843.

Marzo C, Díaz AB, Caro I, Blandino A. Valorization of agro-industrial wastes to produce hydrolytic enzymes by fungal solid-state fermentation. Waste Manag Res. 2019;37:149–56.

Ellouzi SZ, Driss D, Maktouf S, Neifar M, Kobbi A, Kamoun H, et al. Isolation and characterization of starch from industrial fresh pasta by-product and its potential use in sugar-snap cookie making. J Food Sci Technol. 2015;52:5754–62.

Kalia S, Bhattacharya A, Prajapati SK, Malik A. Utilization of starch effluent from a textile industry as a fungal growth supplement for enhanced α-amylase production for industrial application. Chemosphere. 2021;279: 130554.

Shruthi BR, Achur RNH, Nayaka BT. Optimized solid-state fermentation medium enhances the multienzymes production from Penicillium citrinum and Aspergillus clavatus. Curr Microbiol. 2020;77:2192–206.

Cripwell RA, Favaro L, Viljoen-Bloom M, van Zyl WH. Consolidated bioprocessing of raw starch to ethanol by Saccharomyces cerevisiae: achievements and challenges. Biotechnol Adv. 2020;42: 107579.

Kharoliya S, Ruhal R, Kataria R. Microbial production of amylase using lignocellulosic biomass: recent developments and prospects. Res J Biotechnol. 2022;17:192–9.

Sahnoun M, Kriaa M, Elgharbi F, Ayadi D-Z, Bejar S, Kammoun R. Aspergillus oryzae S2 alpha-amylase production under solid state fermentation: optimization of culture conditions. Int J Biol Macromol. 2015;75:73–80.

González MI, Álvarez S, Riera F, Álvarez R. Economic evaluation of an integrated process for lactic acid production from ultrafiltered whey. J Food Eng. 2007;80:553–61.

Krull S, Brock S, Prüße U, Kuenz A. Hydrolyzed agricultural residues—low-cost nutrient sources for l-lactic acid production. Fermentation. 2020;6:97.

Ma K, Cui Y, Zhao K, Yang Y, Wang Y, Hu G, et al. d-Lactic acid production from agricultural residues by membrane integrated continuous fermentation coupled with B vitamin supplementation. Biotechnol Biofuels Bioprod. 2022;15:24.

Qiu Z, Fang C, Gao Q, Bao J. A short-chain dehydrogenase plays a key role in cellulosic d-lactic acid fermentability of Pediococcus acidilactici. Bioresour Technol. 2020;297: 122473.

Liu P, Zheng Z, Xu Q, Qian Z, Liu J, Ouyang J. Valorization of dairy waste for enhanced d-lactic acid production at low cost. Process Biochem. 2018;71:18–22.

López-Gómez JP, Unger P, Schneider R, Venus J. From upstream to purification: production of lactic acid from the organic fraction of municipal solid waste. Waste Biomass Valorization. 2020;11:5247–54.

Marzo C, Díaz AB, Caro I, Blandino A. Effect of several pretreatments on the lactic acid production from exhausted sugar beet pulp. Foods. 2021;10:2414.

López JA, da CostaLázaro C, dos Reis CL, Freire DMG, de Castro AM. Characterization of multienzyme solutions produced by solid-state fermentation of babassu cake, for use in cold hydrolysis of raw biomass. Biochem Eng J. 2013;77:231–9.

Acknowledgements

Not applicable.

Funding

Open Access funding enabled and organized by Projekt DEAL. The authors received financial support from the University of Cádiz through the Margarita Salas Post-doctoral fellowship (UCA/R155REC/2021), financed by Spanish Government (Ministerio de Universidades) and by European Union-Next GenerationEU. Results presented here by authors have been carried out in the framework of CAFIPLA project. This project has received funding from the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation program under grant agreement No. 887115.

Author information

Authors and Affiliations

Contributions

Conceptualisation, JPL-G, CM-G; methodology, JPL-G, CM-G; investigation, CM-G; resources, JV; data curation, JPL-G, CM-G; writing—original draft preparation, JPL-G, CM-G; writing—review and editing, JPL-G, CM-G, JV; visualisation, JPL-G, CM-G; supervision, JPL-G. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable. All the authors agree to the submission and publication of this manuscript.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Marzo-Gago, C., Venus, J. & López-Gómez, J.P. Production of lactic acid from pasta wastes using a biorefinery approach. Biotechnol Biofuels 15, 128 (2022). https://doi.org/10.1186/s13068-022-02222-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13068-022-02222-x