Abstract

The adherence of sputtered Au layers on glass substrates used for surface plasmon resonance (SPR) analysis is very weak. This is usually compensated using a thin Cr or Ti intermediate layer. In this study, a 10-nm sputtered Ag layer (instead of usual Cr or Ti layer) was used as an adhesive intermediate layer between the 40-nm Au layer and the glass substrate. The effect of successive heat treatment at different temperatures on the Au layer adherence and SPR resonance characteristics has been studied. Pull off tests and stability against treatment in boiling water tests have been used for the assessment of Au layer adherence. Based on SPR analysis and pull off and boiling water tests, it is shown that an optimum annealing temperature of 250°C exists for which the Au/Ag/glass substrate composite layer possesses a reasonable adherence along SPR sensitivity.

Similar content being viewed by others

Background

The Au nanofilms deposited on borosilicate glass substrates have gained ever increasing application of modern technologies such as surface plasmon resonance (SPR) biosensors because of their high conductivity and chemical inertness. Fifty nanometers is a conventional thickness for obtaining a proper SPR response from Au/glass composite layers [1, 2]. Such nanofilms are usually produced by physical evaporation [3] and chemical vapor deposition of the metal [4], among the other methods.

It is well known that such coating processes suffer from a severe drawback: weak adherence of the Au layer to the substrate. To overcome the aforementioned drawback, two main techniques that have been reported in the literature are used sequentially: (a) implementation of Cr or Ti thin intermediate layers, usually by radio frequency (RF) sputtering and then (b) thermal annealing of the composite Cr(Ti)/Au layer.

To enhance the adherence of the Au layer to the gold substrate, usually a 1- to 5-nm Cr [5–8] or Ti [9–12] layer is used as an intermediate layer. Sexton et al. [9] showed that Ti is preferred over chromium as it less strongly absorbs light and less prone to variations in transmission.

Thermal treatment has been superimposed to the fabrication procedure above to enhance the ultimate layer properties. It is well known that thermal treatment of the gold nanolayer/glass composites decreases the SPR response, especially at high annealing temperatures [2]; this thermal treatment results in the coalescence of the gold particles, increasing the mechanical strength of the gold layer. SPR depends strongly on the nanoparticle layer structure and morphology [2, 13, 14]. Annealing has a strong influence on the film properties [15], and this may also be used to alter the film properties in a controlled way [16]. Markert et al. [16] showed how the substrate temperature during sputter deposition; a subsequent isochronous annealing process determined the surface topography and the electrical resistivity of thin polycrystalline gold films deposited on float glass. Snopok et al. [8] optimized the thermal treatment procedure for Au films (40 to 60 nm) sputtered on glass substrates containing a 1-nm chromium under layer [8]. They did not perform any stability test on the annealed layers. They realized that the composite layer should not be treated at temperatures exceeding 120°C in order to preserve a reasonable SPR response signal.

3-Mercaptopropyltrimethoxysilane has also been used for improving the adherence of gold to glass substrates [7] due to the chemical affinity of the -SH group with Au. In the latter work, the Au/glass substrate composite layer is further thermally treated at 300°C for 5 to 10 min to reduce the surface roughness and increase the mechanical stability of the Au film.

Zynio et al. [17] studied the effect of using Au/Ag bimetallic layers on the sensitivity of affinity sensors based on surface plasmon resonance. They did not use any Cr or Ti intermediate layer. They aimed at obtaining a higher signal-to-noise ratio by introducing Ag as a primary layer, a high shift of the resonance angle using the second Au layer for a total composite layer thickness of 50 nm. Their work lacks a proper study of the adherence of the bimetallic layer to the substrate under study. We show in the present work that such bimetallic layers suffer from a low adherence to the glass substrate. This is while such composite layers are usually further treated with different chemical agents at different temperatures and may be eroded during the washing in rinsing steps. In other words, it is imperative to improve the mechanical adherence of such bimetallic layers in order to make them industrially attractable.

The aim of the present work is to introduce a new strategy for increasing the adherence and mechanical stability of Au thin films (50-nm thickness) on glass substrates while keeping a reasonable SPR signal response. We show that it is possible to enhance the adherence of the Au layer by implementing an intermediate 10-nm Ag layer, employing an optimal further heat treatment step. As far as the SPR response characteristics are concerned, application of Ag intermediate films is supposed to be superior to Cr and Ti. This is due to the higher value of |ϵr/ϵi | (the ratio of the real to imaginary part of the dielectric constants) of Ag with respect to other metals [3].

We have investigated the effect of thermal annealing on the SPR response characteristics and adherence of the Au/Ag composite layer on the glass substrate. To the knowledge of the authors of this work, the adherence of the treated gold layer to its substrate has not been considered in a thorough fashion so far. Szunertis et al. [4] studied the effect of treating the annealed layers in basic and acidic solutions at room temperature on the change in the SPR behavior before and after treatment. This is a rather simple test and does not give a proper insight about the adherence of the layer. To obtain more reliable information on the adherence of the Au layer on the glass substrate, two kinds of layer stability tests have been devised: (a) resistance to boiling water for a predetermined time and (b) pull off tests. The philosophy behind the first test is that in many applications, the gold-coated chips are subjected to thermal treatments therefore creating thermal shocks in aqueous solutions. It is then imperative that the layer withstands thermal shocks as the linear expansion coefficient of the Au layer is substantially different from that of the glass substrate. After treatment with boiling water, the layer should not totally or partially detach from the glass substrate and should keep its SPR response. It is a qualitative test but of relevant importance. The results of the pull off test involve the adherence characteristic of the nanolayer on the glass substrate. Pull off tests are widely used for assessing the interfacial delamination properties of thin layers and coatings of optical devices [18], and the theory behind has been thoroughly elaborated. In our case, they provide a meaningful interpretation of the adherence of the treated nanolayer for withstanding conventional mechanical manipulations.

The SPR behavior of Au/glass substrate composite layers (as-synthesized and annealed at different temperatures), and their stability is presented in the first part of the present work. This is essential for a rational discussion of the second part of this work. In the second part, the same characteristics of the Au/Ag/glass substrate composite layers are presented and compared with the results of the first part.

Results and discussion

Figure 1a,b,c shows the AFM topologies of the as-deposited and annealed Au layer films at 250°C and 400°C for 60 min. The scan area of the images is 2,500×2,500 nm2. Table 1 shows the corresponding roughness values. It is observed that the average surface roughness of the gold film gradually increases with increasing the annealing temperature. This is mainly attributed to some sort of sintering of the original gold particles and the creation of larger particles. An eightfold increase of the average surface roughness is observed in the sample treated at 400°C with respect to the as-deposited sample. However, for an annealing temperature of 100°C, the surface roughness remains practically intact. A clear change in the surface roughness and surface topology is observed for annealing temperatures higher than 200°C. The trend described above is well known in the art. Grain mobility and coalescence is considered the predominant mechanism responsible for the morphological change induced by annealing [19].

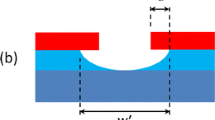

Apart from the mere sintering of the Au particles, the authors of this work present an additional mechanism for explaining the improvement of the adherence of Au to the glass substrate. This is schematically shown in Figure 2. Referring to this figure, the effect of heat treatment is not merely the coalescence of the gold particles. Another phenomenon also takes place: the gold particles undergo a better wetting of the hills of the glass substrate (Ra ≈ 0.34 nm), resulting in a better ‘entanglement’ of gold particles with the glass protuberances. The latter phenomenon results in a better adherence of the gold thick film to the glass substrate.

The effect of annealing temperature on the SPR response and transmission mode absorbance of the Au coated samples is shown in Figure 3. It is observed that the resonance angle and percent absorbance remain approximately constant upon heat treatment at 100°C and 150°C. Actually, the change in the depth of the SPR curve is 0.0% and 1.8% for annealing temperatures of 100°C and 150°C, respectively (Figure 3b). Further increase of the annealing temperature reduces sharply the SPR response. This is in accordance with the trend of topology change with increasing annealing temperature. The ‘sintering’ of the gold particles is pronounced at temperatures equal or higher than 200°C. The absorbance undergoes significant reduction at an annealing temperature of 300°C and assumes its smallest value at 400°C throughout the wavelength span under consideration. Such a behavior has been reported before [2] and is attributed to the formation of hills and valleys due to the coalescence of gold particles. The hills provide ‘low absorbance’ regions for the passing light beam thus resulting in lower absorption values.

At this stage, it is noteworthy to consider the optical characteristics of the samples coated with 10 nm Ag and 40 nm Au. The SPR response curves (Figure 3) show the same trend as the Au film as a function of annealing temperature. The change in the SPR response is 0.0 and 4.8% at 100°C and 150°C, respectively. The attenuation of the SPR response is somewhat stronger at 150°C for the composite layer compared to the Au/glass composite layer (1.8%). The SPR signal undergoes a 28% reduction at 200°C, being still sharp. The SPR response vanishes at 400°C. The optical behavior as a function of temperature has a peculiarity not observed for the Au/glass composite layer. The SPR angle of Au/Ag/glass composite changes significantly with increasing the annealing temperature. Figure 3b shows the latter phenomenon. Interestingly, the rate of change of the SPR angle has a maximum at 200°C.

Figure 1d,e,f shows the surface morphology of the as-deposited, annealed at 250°C, and annealed at 400°C Au/Ag composite layers, respectively. When compared with Figure 1a,b,c, it is observed that the introduction of the Ag as an intermediate layer results in a completely different sintering behavior of the gold particles. Diffusion of Ag atoms into the Au film prevents the formation of large Au particles and results in the formation of a well-patterned surface lattice-like collection of spindly entities. It is not clear at this stage if the elimination of the SPR signal is due to a different surface topology or because of different bulk properties of the composite layer.

The layer stability characteristics of the Au/glass composite layers as a function of annealing temperature is summarized in Figure 4. It is observed that the original Au/glass composite layer does not pass the boiling water stability test. Heat treatment in the temperature range of 100°C to 400°C results in Au/glass composite layers that pass this test while the original Ag/Au composite film passed the latter test. In other words, the mere introduction of Ag as an intermediate layer enhances significantly the adherence of Au to the glass substrate. This mechanical characteristic is maintained after thermal annealing up to 400°C.

Referring to Figure 5, it is observed that the SPR response of the Au/Ag/ glass composite layers follow a different trend compared to the Au/glass layers. For the Au/glass composite layers, only the sample treated at 400°C passes this test and shows no SPR response (Figure 5a). According to Figure 5, heat treatment of the Au/Ag/glass composite layers in the temperature range 100°C to 200°C enhances the adherence of the layer while keeping a reasonable SPR output signal characteristic. It is observed that an annealing temperature of 250°C results in intact composite layers after performing the pull off test. This is while the SPR signal is still of a reasonable intensity ca. 40% reduction with respect to no annealing (Figure 5b). Composite layers heat-treated at temperatures higher than 250°C posses a reasonable adherence but show a weak SPR characteristic.

Conclusion

Summed up, it may be stated that the mere introduction of a 10-nm intermediate layer enhances significantly the Au layer adherence to the glass substrate while the Au/Ag/substrate composite shows acceptable SPR characteristics. However, this is not enough as the composite layer chip should withstand sever eventual physical successive treatments during fictionalization processes prior to SPR analysis. The last results showed that such a resistance may be achieved only by an optimal treatment method of the as-synthesized Au/Ag/glass composite layer.

Methods

H2O2 (30 wt.%), H2SO4 (94 wt.%) were purchased from Merck Company (Whitehouse Station, NJ, USA). Triply distilled water was used. The substrate surfaces were initially and thoroughly treated in piranha solution. This pretreatment results in an approximately complete cleaning of the surface. In addition, it results in the change of the chemical structure of the exposed glass surface, eventually increasing the concentration of silanol surface groups. Glass substrates (microscope slides, soda-lime glass) were cleaned with piranha solution (3:1 vol. ratio, H2SO4/H2O2) for 30 min at 80°C. After cooling, the samples were rinsed with water and dried under nitrogen gas flow.

Au layers with a thickness of about 50 nm were sputter-deposited on cleaned glass slides (7×7×1 mm3 pieces) using a BAL-TEC SCD 005 DC sputtering system. The surface roughness (Ra) of the initial slides was 0.34 nm. No intermediate Cr or Ti layer was used. Sputtered metal thickness was determined using a Stylus Profilometer DEKTAK3 (Veeco, Plainview, NY, USA ) instrument. In the case of Au/Ag films, the glass substrates were coated with a 10-nm Ag film in the first step and with a 40-nm Au film in the second step.

The samples were heated to the desired temperature (100°C, 150°C, 200°C, 250°C, 300°C, 400°C) using an electrical furnace with a heating rate of 5°C/min in ambient air and treated for 1 h.

The analysis of the surface topology of the original and treated gold films was performed by a Nanoeducator AFM apparatus using a non-contact mode. Transmission-mode absorption spectra were obtained using an Ocean Optics UV-visible spectrometer (Dunedin, FL, USA). An Iranian SPR instrument (Nano SPR) was used to investigate the SPR characteristics of the original and treated samples [20]. The resolution of this version of the SPR determination apparatus was 0.01°. The goniometer of the nano SPR system worked with a θ to 2θ geometry. A 2-mW He-Ne gas source was used for producing the laser beam (632.8 nm). Glycerin was used as an interface layer between the borosilicate glass prism and the glass slides.

The layer stability was evaluated by placing the sample in a 200-cm3 beaker containing 50 cm3 boiling water for 15 min. Partial or full detachment of the gold layer was considered as a failed experiment. If the sample remained constant and produced the original SPR response with less than 0.02° change in the SPR angle, the experiment was considered successful. Each stability test was repeated twice.

The pull off test was performed as follows: an adhesive tape was put horizontally on a holder, then the composite layer (7×7×1 mm3) was put on it so that the metal came into contact with the tape. Afterwards, a 100-g standard weight was put on the glass side of the slide for 30 s. Afterwards, the weight was raised and the slide was detached manually from the tape. Each pull off test was repeated twice.

References

Huanga Y, Qiua H, Wanga F, Pana L, Tiana Y, Wu P: Effect of annealing on the characteristics of Au/Cr bilayer films grown on glass. Vacuum. 2003, 71: 523–528. 10.1016/S0042-207X(03)00093-9

Serrano A, Rodríguez de la Fuente O, García MA: Extended and localized surface plasmons in annealed Au films on glass substrates. J Appl Phys 2010, 108: 074303–074310. 10.1063/1.3485825

Mitsushio M, Miyashita K, Higo M: Sensor properties and surface characterization of the metal-deposited SPR optical fiber sensors with Au, Ag, Cu, and Al Sens. Actuators A 2006, 125: 296–303. 10.1016/j.sna.2005.08.019

Szunertis S, Coffinier Y, Janel S, Boukherroub R: Stability of the gold/silica thin film interface, electrochemical and surface plasmon resonance studies. Langmuir. 2006, 22: 10716–10722. 10.1021/la060793o

Parisi A, Cino AC, Busacca AC, Cherchi M, Riva-Sanseverino S: Integrated optic surface plasmon resonance measurements in a borosilicate glass substrate. Sensors. 2008, 8: 7113–7124. 10.3390/s8117113

Jang LS, Liu HJ: Fabrication of protein chips based on 3-aminopropyltriethoxysilane as a monolayer. Microdevices. 2009, 11: 331–338. 10.1007/s10544-008-9239-7

Hirlekar Schmid A, Stanca SE, Thakur MS, Ravindranathan Thampi K, Raman Suri C: Site-directed antibody immobilization on gold substrate for surface plasmon resonance sensors Sens. Actuators 2006, 113: 297–303. 10.1016/j.snb.2005.03.018

Snopok BA, Kostyukevich KV, Lysenko SI, Lytvyn PM, Lytvyn OS, Mamykin SV, Zynyo SA, Shepeliavyij PE, Kostyukevich SA, Shirshov Yu M, Venger EF: Optical biosensors based on the surface plasmon resonance phenomenon: optimization of the metal layer parameters. Semicond Phys Quantum Electron Optoelectron 2001, 4: 56–69.

Sexton BA, Feltis BN, Davis TJ: Characterisation of gold surface plasmon resonance sensor substrates Sens. Actuators A 2008, 141: 471–475. 10.1016/j.sna.2007.10.020

Hoogvliet JC, van Bennekom WP: Gold thin-film electrodes: an EQCM study of the influence of chromium and titanium adhesion layers on the response. Electrochimica Acta. 2001, 47: 599–611. 10.1016/S0013-4686(01)00793-9

Szunerits S, Boukherroub R: Electrochemical investigation of gold/silica thin film interfaces for electrochemical surface plasmon resonance studies. Electrochemistry Communications. 2006, 8: 439–444.

Kim JM, Kim SH, Ohashi T, Muramatsu H, Chang SM, Kim WS: Construction of simultaneous SPR and QCM sensing platform bioprocess. Biosyst Eng 2010, 33: 39–45. 10.1007/s00449-009-0370-5

Yu K, Lance KK, Nobuyuki S, Tetsu T: Morphologies and surface plasmon resonance properties of monodisperse bumpy gold nanoparticles. Langmuir. 2008, 24: 5849–5854. 10.1021/la703903b

Armelao L, Barreca D, Bottaro G, Bruno G, Gasparotto A, Losurdo M, Tondello E: RF-sputtering of gold on silica surfaces: Evolution from clusters to continuous films. Mat Sci Eng 2005,2005(25):599–603.

Švorˇcík V, Siegel J, Šutta P, Mistrík J, Janíˇcek P, Worsch P, Kolská Z: Annealing of gold nanostructures sputtered on glass substrate. Appl Phys A 2011, 102: 605–610. 10.1007/s00339-010-6167-1

Markert C, Lutzenkirchen-Hecht D, Fraham R: Structural and electrical properties of thin d.c.magnetron-sputtered gold films deposited on float glass Structural. Surf Interface Anal 2006, 38: 715–718. 10.1002/sia.2258

Zynio SA, Samoylov AV, Surovtseva ER, Mirsky VM, Shirshov YM: Bimetallic layers increase sensitivity of affinity sensors based on surface plasmon resonance. Sensors. 2002, 2: 62–70.

Zuo S, Wan KT, Dillard DA: A theoretical and numerical study of thin film delamination using the pull-off test. Int. J Sol Struc 2004, 4: 717–730.

Lee KC, Lin SJ, Lin CH, Tsai CS, Lu YJ: Size effect of Ag nanoparticles on surface plasmon resonance. Surf. Coat Techn 2008, 202: 5339–5342. 10.1016/j.surfcoat.2008.06.080

Sahebghadam Lotfi A, Falamaki C, Pourghafoor B, Sadeghi A, Faraji F: Iranian Patent 68727. 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

Both authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Ghorbanpour, M., Falamaki, C. A novel method for the production of highly adherent Au layers on glass substrates used in surface plasmon resonance analysis: substitution of Cr or Ti intermediate layers with Ag layer followed by an optimal annealing treatment. J Nanostruct Chem 3, 66 (2013). https://doi.org/10.1186/2193-8865-3-66

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-66