Abstract

Infilled walls are normally considered as nonstructural elements. However, these walls are effective in carrying lateral loads. In this regard, an experimental investigation was planned and conducted to study the effect of braced and partially concrete-infilled, reinforced concrete (RC) frames in comparison to the bare frames. All these frames were tested up to collapse and subjected to only horizontal loads to obtain an effective and possible solution for soft story. In comparison to bare RC frames, partially infilled frames have more lateral load capacity. Central bracing is more effective than that of corner bracing. For the same load, braced and partially infilled frames deflected significantly less than that of the bare frames. Based on experimental observations, a mathematical model has been proposed to calculate theoretical ultimate load for braced and partially infilled RC frames.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Usually, the infill walls of a building are not considered as elements of the force-resisting system. In many instances, structural walls are assumed to resist racking loads due to wind and earthquake. Such walls are generally known as shear walls and can also carry vertical loads and are designed as an integral part of the structures. Other types of walls are called filler panels, which are used to partition space or to enclose structures. Such panels occupy a rectangular space between two adjacent columns and two successive stories. But these filler panels can have considerable influences on the lateral response of a building. Nowadays, soft story in buildings is common at the parking level as there is absence of infill walls, whereas the stories above are filled with partition walls. Such frames have less capacity to bear lateral loads. Portal frames tested up to collapse have drawn attention of several investigators in the recent past for inherent structural advantage of such frames.

Available literature review shows that attempts to evaluate the strength and stiffness of these frames. Infilled frames investigated (Wood 1958) by conducting several tests on concrete encased steel frames with brick and concrete-infilled panel walls on the resistance of structural frame works against racking loads. (Benjamin and Williams 19581959) had tested many prototypes as well as models of RC frames with plain and reinforced concrete infill walls. The foundations were considered rigid. It was observed that there was no scale effect; i.e., test can be performed on any scale model, and results of the scale models were found to be consistent with the prototype. (Smith 1966) investigated the behavior of square frames and tried to compare the theoretical results with experimental ones. He had derived expressions for diagonal stiffness and suggested that the infill acts as a diagonal strut. A method had been described by (Mallick and Severn 1967) which make use of finite element concept. For the purpose of calculation, the actual frame with infinite degrees of freedom was replaced by a system with finite number of degrees of freedom, and the elements of infill were assumed as rectangular in shape. The approach to analyze infilled frames by (Mainstone 1971; Smolira 1973) was based on the concept of diagonal struts. (Barua and Mallick 1977) had tested a series of mortar-infilled model steel frames with a tightly fitted, homogeneous and elastic infill. Tests were performed by Mali and Saldoga (1981) on RCC frames with brick as infill. In addition to the racking load, they applied a uniformly distributed vertical load, which caused pre-compression of wall and reported cracking and failure behavior of infilled frames. Their experimental values were close to the theoretical values.

(Liauw and Kwan 1983) had proposed plastic theory for analysis to both single story and multi-story integral infilled frames. The problem of non-integral infilled frame was overcome by introduction of material with strong bond or shear connectors at the frame/infill interface. In 1999 in Kocaeli (Turkey), the complete failure of the first story or the bottom two stories happened due to earthquake. (Dolšek and Fajfar 2001) demonstrated that a soft story mechanism is formed in such structural systems if the intensity of ground motion is above a certain level and collapse will occur if the global ductility of the bare frames is low. (Hashmi and Alok 2008) studied an analytical investigation of seismic performance of masonry-infilled, RC-framed building with an open storey generally termed as soft storey. It was observed that if the storey is partially infilled (in comparison to no infills), it decreases story drift and deformations in the column in the storey and reduces the damage to columns and overall frame. The main objective of (Liao 2010) study was to develop and validate a seismic design methodology for reinforced concrete special moment frames which is able to produce structures with predictable and intended seismic performance. For existing reinforced concrete buildings, (Viswanath et al. 2010) retrofitted to overcome deficiencies to resist seismic loads by using concentric steel bracing systems. A reinforced concrete frame is modeled for finite element sensitivity analysis by (Alam and Dookie 2012) followed by finite element reliability analysis under both static and dynamic load cases. Building damage by earthquake action is a serious problem; in this regard, (Rachana and Mohod 2012) studied seismically deficient structures by carrying out the pushover analysis of frame structures using structural analysis and programming software. Forces increased as per the height of structure: low-rise structures have higher resonant frequency and hence lower-frequency, high-rise structures had been studied. As per (Vijayakumar and Venkatesh Babu 2012), Indian buildings built over the past two decades are seismically deficient because of the lack of awareness regarding the seismic behavior of structures. This paper aims to evaluate a selected existing reinforced concrete building in zone III to conduct pushover analysis. The analysis shows the pushover curves, capacity spectrum, plastic hinges, and performance level of the existing building.

Considering all these factors, high-yield, strength mild-steel bracings with partial infills of concrete, the RC frames were tested under lateral loads to understand the behavior and contribution of infill. In this study, tests are conducted on 14 numbers of different models of bare, braced, and infilled frames as shown in Table 1. For main reinforcement and bracings, tor steel bars and steel square bars are used for frames. The behavior of frames has been studied with respect to the following:

-

Bracing system-bare frames and different types of braced RC frames

-

Partial infill-steel-braced RC frames without infill and partially infilled with concrete

-

Strength and deformation of frames

In the present work, experiments have been performed on models up to failure. Studies have been carried out on single-bay, single-story frames. For each frame, two models were tested, and the average value is considered for experimental loads and deflections.

Methods

Experimental set-up

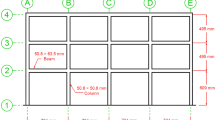

For the experimental setup, the RC portal frame with a welded base plate was rigidly bolted to the supporting girder. All the experiments were performed on models with single-bay, single-story frames. The two models were tested of each category as mentioned in Table 1. The details of the model's dimensions, proving ring, loading jack, and position of the dial gauge are shown in Figure 1. The different bracing systems such as corner, central and diagonal, and the steel skeleton of reinforcement are shown in Figure 2. The frame consists of two vertical members of height 400 mm connected by a horizontal member at the top with a span of 600 mm. For the bare frames' proving ring capacity of 10 kN and for remaining frames, a hydraulic jack of 500 kN was attached to measure the load. Dial gauge with range of 20 mm was used to measure the horizontal displacement at the beam level. The size of column is 60 mm × 100 mm and for the beam is 100 mm × 100 mm. Side cover plates of 10 mm thick were welded to such frames, and these plates were bolted to the girder by four bolts of 20-mm diameter. The RC frames and infill of concrete were cast by laying the frame on the horizontal surface.

Materials for models and control specimen

The following materials were used for the frame, bracing, and the partial infill:

-

Tor steel of 8 mm of weight 3.9 N/m as main reinforcement and 6 mm for ties and stirrups were used for the RC frame.

-

For bracings, 10-mm square bars of high-yield, strength mild- steel is used.

-

The partial infills of concrete with thickness of 50 mm which are made up with cement, river sand, and 12-mm coarse aggregate of 1:1.5:3 ratios were used.

Three samples for the tensile test of 8-mm and 6-mm tor steel and high-yield strength square bars of 10 mm were prepared and tested to obtain the characteristic strength and yield stress of steel. Three cubes of size 150 mm × 150 mm × 150 mm were cast and tested after 28 days to determine the compressive strength of concrete, and slump was also observed for fresh concrete.

Test procedure

While conducting the test on the various frames, bolts were fully tightened ensuring full fixity at the supports. The dial gauge was checked for proper functioning before it was mounted in the position, and the contact between the dial gauge tip and the frame surface was ensured. The jack centerline was aligned along the beam axis.

The horizontal load was applied with the help of a screw/hydraulic jack. The load was applied at a uniform rate. The load and the deflection were recorded at regular intervals for each test setup. The load was applied continuously until it remained constant for a particular time on the proving ring and then moved in a reverse order. This is called as plastic state condition. The collapse load corresponding to this stage was recorded as an ultimate load.

Results

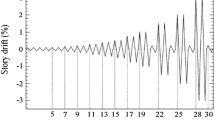

While conducting the experiments, precautions were taken to keep the proving ring at its position as it was trying to lift itself. During load application, attention was paid to crack formation and its propagation in the infill. The direction and progress of cracks at different load levels were recorded. The locations and extent of loss of contact between the frame and infill were noted down. The final collapse modes were photographed for full details. The compressive strength of concrete mix cubes was observed to be 24.2 N/mm2, tested after 28 days. The value of slump was 50 mm for the fresh concrete. The characteristic strength of 8-mm and 6-mm tor steel is 419 and 350 N/mm2, respectively. The yield stress of bracing bars was observed to be 450 N/mm2, and allowable bending tensile strength was taken as 0.66 times yield stress. The increase in lateral load capacity of braced frames R2, R3, and R4 with respect to the bare frame R1 is 167.3%, 220.8%, and 301%, respectively. The contribution of infill is 20%, 16.6%, and 126.6% for R5, R6, and R7 in comparison to the braced frames of similar type without an infill as shown in Table 2. The load deflection curves for R1, R2, R3, and R4 and R5, R6, and R7 are shown in Figures 3, 4, 5 respectively. These figures show that central-braced infilled frames are more effective than that of corner-braced and diagonal-braced, partially infilled frames for the deflection criteria. The comparison of experimental and theoretical ultimate loads for various frames is shown in Table 2. Figures 6, 7, 8, 9, 10, 11, 12, illustrate the crack pattern indicated by the red painted lines for all bare, braced, and infilled frames correspondingly.

Proposed analytical method

The analytical methods for bare, braced, and infilled frames are described as follows.

Method 1: proposed methods for bare RC frame

While particularly applying the load on the bare frames, it was observed that although failure mechanism was predominantly the sway mechanism, plastic hinges are formed at base of column and at junction of column and the beam. The idealization of the proposed method is illustrated in Figure 13. To develop a mathematical model certain assumptions were made:

-

1.

The concrete material is homogenous and isotropic.

-

2.

The mode of collapse is a sway mechanism for frames.

-

3.

For frames at joints, initial fixity exists perfectly.

-

4.

The small deformation theory is applicable.

Let virtual displacement, corresponding to sway mode, be represented by ‘∆’ at q and r and hinge rotation ‘θ’ at p, q, r, and s.

The external work done due to ultimate load is as follows:

The internal work done due to hinge rotation is presented as

where external work done = internal work done is shown as

Here M p depends on σc. The value of M p = [(0.67) * (σ c /γc) * Z p].

Method 2: proposed methods for braced and partially infilled RC frame

The proposed analytical model to calculate theoretical ultimate lateral load capacity is on the basis of the experimental observations of crack patterns and formation of plastic hinges for various braced and partial concrete-filled RC frames. It is observed that due to compressive force from diagonal compression band, tensile cracks are developed along tension column for all RC-infilled frames. The idealization of the proposed method is illustrated in Figure 14. To develop a mathematical model certain assumptions were made:

-

1.

Plastic hinges are formed at column base and column beam junction, and mode of collapse is the sway mechanism.

-

2.

For partially infilled frames, perfect initial fit exists.

-

3.

The small deformation theory is applicable.

The crushing strength of concrete infill was taken as 0.67 times the experimental compressive strength. As per assumption, the failure mode is the sway mechanism with plastic hinges at p, q, r, and s. For all infills, strength is considered along the diagonal compression only.

Let virtual displacement, corresponding to the sway mode, be represented by ‘∆’ at q and r and hinge rotation ‘θ’ at p, q, r, and s. External work done due to the ultimate load and internal work done due to hinge rotation are presented as Equations 1 and 2, respectively.

Internal work done due to infill can be presented as follows:

where external work done = internal work done is shown as

and where the value of ‘Fc’ for various frames are as follows:

-

1.

For braced RC frames

(6) -

2.

For concrete partial infill

(7)

The values of N1 are shown in Figure 2 and are obtained from bracing present in diagonal compression strut and H 2 = (3/4) H. The value of WC will be taken as 15 H/B and 20 H/B for R5 and R6, respectively.

Method 3: proposed methods for diagonally braced and infilled RC frame

On the basis of the experimental observations of crack patterns and formation of plastic hinges for diagonal bracing and concrete-filled RC frames, plastic hinges are formed at column base and column beam junction, and the mode of collapse is the sway mechanism. To develop a mathematical model, certain assumptions were made:

-

1.

The crushing strength of concrete infill was taken as 0.67 times the experimental compressive strength.

-

2.

For infilled frames, perfect initial fit exists.

-

3.

The small deformation theory is applicable.

The idealization of the proposed method is illustrated in Figure 15. As per assumption, the failure mode is a sway mechanism with plastic hinges at p, q, r, and s. For all infills, strength is considered along the diagonal compression only.

Let virtual displacement, corresponding to the sway mode, be represented by ‘∆’ at q and r and hinge rotation ‘θ’ at p, q, r, and s.

External work done due to ultimate load and internal work done due to hinge rotation are presented as Equations 1 and 2, respectively.

The internal work done due to infill is as follows:

where external work done = internal work done as

Where the value of ‘Fc’ for various diagonally braced frames are as follows:

-

1.

For braced RC frames

(10) -

2.

For concrete infill

(11)

The values of N1 are shown in Figure 2 and are obtained from the bracing present in the diagonal compression strut. The value of WC = 2C X sin α. The value of C Y = C X tan α, where the value of C X has been taken as zero for R4 and 50 B/H for R7.

Discussion

The behavior of partially infilled, braced RC frames subjected to racking load was studied with different patterns of steel bracings such as corner, central, and diagonal and infilled material such as concrete. It is observed that due to the compressive force along the diagonal compression band, tensile cracks are developed along tension column for all RC-infilled frames. The cracks developed at various places are indicated by the red painted lines on different infills as shown in figures. It can be observed from the photo plates that failure was predominately caused by the sway mechanism. The partial safety factor for concrete ‘γc’ is taken as 1.5. The ultimate load versus deflection comparison shows a significant increase in the lateral load capacity for braced and partially infilled frames than that of the bare frames. Although no lugs were provided between partial infill and the RC frames, the concrete partial infill contribution was still observed to be 20% more than the braced frames.

Since cracks developed prior to failure, the tensile strength of concrete does not take into account for ultimate strength of infill. Though diagonally braced system shows better results than that of the other two systems, practically, it is difficult to implement as it would hinder the movement of users around the space and thus central bracing system is more effective for soft story frames.

Shear walls which are used in all four corners of multi-story buildings can be strengthened by using diagonal steel bracing with concrete infill, as its lateral strength contribution is remarkable. It can be further seen that the experimental ultimate loads are fairly close to the theoretical ultimate loads based on the proposed method.

Conclusions

The purpose of this study was to evaluate the strength of braced and partially infilled RC frames then those studied by previous researchers as well as to add to the database of strengthening test results in order to lead to changes or acceptance in design codes and standards. To study the ultimate load two bare, six braced and six partially infilled RC frames were constructed and tested up to collapse.

Based on the results of the investigation, the following findings and conclusions are presented for such frames:

-

If the infill is stronger than the frame, the failure mode corresponds to sway mechanism with major tension cracks along the tension column. For braced and partially infilled RC frames, possible plastic hinge locations are at the column beam junction and the bottom of column.

-

Based on a comparison with the bare RC frames, braced frames have shown an increase of 167.3%, 220.8%, and 301% in lateral load capacity. It specifies that the contribution of bracings is up to a significant level for the lateral strength for braced frames.

-

All braced and partially infilled braced frames have significantly less deflection in comparison to the bare frames.

-

Practically, the partially infilled and center-braced system may be a viable solution which may not affect architectural or interior function than that of corner and diagonal bracing partially infilled system for soft story frames.

-

For shear walls, use of diagonal steel bracing with RCC infill will be more effective, as its lateral strength contribution is remarkable.

-

Though contribution to the strength of partially infilled frames is 20% in comparison to braced frames, it stiffens the frames considerably.

-

The proposed analytical method gives results close to the experimental results and can be used to calculate ultimate collapse load for such type of infilled system.

It is suggested for future study to use 3D models for testing and analyzing by using ANSYS software.

Authors’ information

SKDD has done his M.Tech. in the field of structural engineering from IIT Mumbai in 1991. He is an associate professor in SSVPS COE Dhule and doing his Ph.D. in the field of structural engineering. He has published papers in the field of structural engineering and building materials. SYK is a Ph.D. and is a professor in K. K. Wagh COE Nasik and has published papers in the field of structural and hydraulics engineering.

Abbreviations

- Asb:

-

Area of square bracing bar (mm2)

- B:

-

Width of frame (mm)

- CX:

-

Effective width of crack along x direction (mm)

- CY:

-

Effective width of crack along y direction (mm)

- FC:

-

Compressive force along diagonal (N)

- H:

-

Height of frame (mm)

- MP:

-

Full plastic moment of the section (N/mm)

- N1:

-

Number of bracing bar in compression zone

- tw:

-

Thickness of partial infill (mm)

- WC:

-

Width of diagonal compression (mm)

- Wu:

-

Theoretical ultimate load (N)

- γc:

-

Partial safety factor for concrete

- Zp:

-

Plastic modulus (mm3)

- ∆:

-

Virtual lateral displacement (mm)

- ∆1:

-

Virtual lateral displacement due to Fc (mm)

- θ:

-

Virtual hinge rotation (radian)

- α:

-

angle between compression diagonal and horizontal (radian)

- σbt:

-

Allowable bending tensile strength of bracing bars (N/mm2)

- σc:

-

Ultimate compressive strength of concrete (N/mm2)

- σy:

-

Yield stress of mild steel bracing bars (N/mm2).

References

Alam MI, Dookie K: Effect of constitutive material models on seismic response of two-story reinforced concrete frame. International Journal of Concrete Structures and Materials 2012, 6: 101–110. 10.1007/s40069-012-0010-3

Barua HK, Mallick SK: Behavior of mortar infilled steel frames. Build Environ 1977, 12: 262–272.

Benjamin JR, Williams HA: The behavior of one storey brick shear walls. ASCE J Struct Div 1958, 84: 1–30.

Benjamin JR, Williams HA: Behavior of reinforced concrete shear wall. Trans Am Soc Civil Eng 1959, 124: 669–708.

Dolšek M, Fajfar P: Soft storey effects in uniformly infilled reinforced concrete frames. J Earth Eng 2001, 5: 1–12.

Hashmi AK, Alok M: Damage forecast for masonry infilled reinforced concrete framed buildings subjected to earthquakes in India. Curr Sci 2008,94(1):61–73.

Liao W-C: Performance-based plastic design of earthquake resistant reinforced concrete moment frames. Doctoral thesis: University of Michigan; 2010.

Liauw TC, Kwan KH: Plastic theory of infilled frames with finite interference shears strength. Proc Inst Civil Eng 1983,75(2):707–723.

Mainstone RJ: On the stiffness and strength of infilled frames. Proc Inst Civil Eng 1971, IV: 57–90.

Mali SG: Model test on R.C. frames with brick infill with vertical and horizontal load. Indian Concrete J 1981, 55: 13–21.

Mallick DV, Severn RJ: The behavior of infilled frame under static loading. Proc Inst Civil Eng 1967, 38: 639–656. 10.1680/iicep.1967.8192

Rachana RG, Mohod MV: Seismic evaluation of framed structures. Int J Sci Eng Res 2012, 3: 1–8.

Smith BS: Behavior of square infilled frames. J Struct Div ASCE 1966,92(1):381–403.

Smolira M: Analysis of infilled shear walls. Proc of Ins Civil Eng 1973, 55: 895–912. 10.1680/iicep.1973.4146

Vijayakumar A, Venkatesh Babu DL: Pushover analysis of existing reinforced concrete framed structures. Eur JSci Res 2012, 2: 195–202.

Viswanath KG, Prakash KB, Desai A: Seismic analysis of steel braced reinforced concrete frames. Int J of Civil Struc Eng 2010, 1: 114–122.

Wood RK: The stability of tall buildings. Proc Ins Civil Eng 1958, 11: 69–102. 10.1680/iicep.1958.2424

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare no competing interests.

Authors’ contributions

SKDD prepared the experimental model, carried out the experiments, drafted the manuscript, and prepared mathematical models. SYK had given the idea, participated in designing the experimental model, helped in the interpretation of experimental output, and also helped in drafting the manuscript. Both authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Damodar Dubey, S.K., Kute, S.Y. Experimental investigation on the ultimate strength of partially infilled and steel-braced reinforced concrete frames. Int J Adv Struct Eng 5, 15 (2013). https://doi.org/10.1186/2008-6695-5-15

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2008-6695-5-15