Abstract

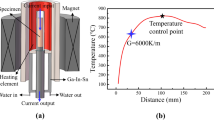

The article considers the current state of theoretical and experimental knowledge of the filtration permeability process during the crystallization of metal alloys using the Karman–Kozeni equation with its practical application to meet a lack of adequate mathematical apparatus for describing the morphological evolution of dendritic structure. In order to solve the problem of modeling, we focus on formation of shrinkage voids during bulk crystallization of multicomponent casting alloys. We base on synthesis of a dimensionless version of the Carman–Kozeni model for permeability of a solidifying two-phase medium and a local version of the system analysis for the formation of the stochastic structure of secondary dendritic branches with continuous capillary-diffusion coalescence of meso-scale model. As part of the system analysis of non-equilibrium crystallization, a continuous change in the temperature of the alloy, the rate of solid phase releasing, the concentration of the residual liquid phase, and the evolution of the dendritic structure are investigated. With the help of numerical analysis, the extreme nature of the filtration permeability of the dendritic structure is established depending on the fraction of the solidified phase. The paper discusses the generalized results of metallographic studies of aluminum alloys, which give grounds to application of the lognormal distribution law of the parameters for the dendritic structure of the alloys and the use of the Monte Carlo method to quantify the local structural heterogeneity of the cast metal.

Similar content being viewed by others

References

K.D. Carlson, S. Ou, R.A. Hardin, C. Beckermann, Metall. Mater. Trans. B 33, 731, (2002)

V.M. Golod, K.D. Saveliev, A.S. Basin, Modelling and Computer Analysis the Crystallization of Iron-based Multicomponent Alloys, (Publishing house, Polytechnic. Univ, Saint-Petersburg, 2008)

V.M. GolodK.I. Emelijanov. Criterial analysis of porosity in castings: real possibilities and prospects, in Proceed. XII All-Russian Foundry Congress, Nizhny Novgorod, 2015, (NSTU n.a. R.E. Alekseev, 2015), 173

R.P. Taylor, J. Shenefelt, J. Berry, R. Luck, Trans. Am. Foundry. Soc., 110, 315 (2003)

A.E. Scheidegger, Physics of Fluid Flow Through Porous Media, (Transl, Gostoptekhizdat, Moscow, 1960)

A.V. Lykov, Heat and Mass Transfer Handbook Energy, (Moscow, 1978).

A. Kumar, M. Zaloznik, H. Combeau, Int. J. Therm. Sci. 54, 33, (2012)

Ø. Nielsen, L. Arnberg, A. Mo, H. Thevik, Metall. Mater. Trans. A 30, 2455 (1999)

C.Y. Wang, S. Ahuja, C. Beckermann, H.C. de Groch III, Metall. Mater. Trans. B 26, 111 (1995)

E. Khajeh, D. Maijer, Acta Mater. 58, 6334 (2010)

G. Chai, L. Backerud, T. Rolland, L. Arnberg, Metall. Mater. Trans. A 26, 965 (1995)

L. Nastac, D.M. Stefanescu, Metall. Mater. Trans. A 27, 4061 (1996)

K.I. Yemelyanov, V.M. Golod, Foundryman of Russia 2, 28 (2013)

V.M. Golod, K.I. Yemelyanov, Ferrous Met. 4, 49 (2014)

G. Khan, S. Shapiro, Statistical Models in Engineering Problems, (Transl, World, Moscow, 1969)

P.K. Sung, D.R. Poirier, S.D. Fellicelli, Modell. Simul. Mater. Sci. Eng. 10, 551 (2002)

V.M. Golod, K.I. Yemelyanov, I.G. Orlova, Ferrous Met. 8, 9 (2013)

V.M. Golod, L.Yu. Dobosh, IOP Conf. Ser.: Mater. Sci. Eng., 192, 012027 (2017)

L.Yu. Dobosh, V.M. Golod, K.D. Saveliev, Assessment the model adequacy of the additive components influence on the crystallization of aluminum alloys, in Proceed. X Intern. sci.-pract. conf. “Foundry production today and tomorrow”, Saint-Petersburg, 2014, (SPbGPU, Publishing house, 2014),366

V.M. GolodPOLYCAST-ARM, Software complex, Certificate of state registration of computer programs, 1 2008611180, 06. 03. 2008, Moscow, 2008

K.D. Saveliev, V.M. Golod, POLYTHERM-TD, Software complex, Certificate of state registration of computer programs, 1 2013661257, 03. 12. 2013, Moscow, 2013

V.M. Golod, L.Yu. DoboshNON/EQUILIBR.KRIST.Modeling, Software complex ALSYS, Certificate of state registration of computer programs, 1 2016616169, 07.06.2016, Moscow, 2016

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Golod, V.M., Dobosh, L.J. & Kim, A.E. Evolution of filtration permeability of dendritic structure in the conditions of capillary – diffusion coalescency of the secondary side branches. Eur. Phys. J. Spec. Top. 229, 225–237 (2020). https://doi.org/10.1140/epjst/e2019-900109-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjst/e2019-900109-0