Abstract

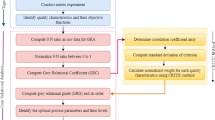

In recent diverse modern multi-disciplinary industries like automotive, aerospace and biomedical, there is comprehensive usage of titanium matrix composite (TMC) for its extraordinary strength and resistive properties. The prime scope of this investigation deals with the development of a new TMC by laser engineering net shaping (LENS) process and recent state-of-the-art advancement of tribo-mechanical and metallurgical properties. Laser process parameters like laser power (P), scan speed (V) and energy input/area (E) are varied. The microstructure and characterization depict an outstanding interfacial bonding between TiB2 and Ti where the best parametric combination is identified. Also, a novel optimization algorithm named as desirable genetic algorithm (DGA) is proposed in this manuscript. The objective functions determined by desirability function are further incorporated in genetic algorithm in MATLAB R2018a to improve the optimized solution. Multi-objective optimization (MOO) is developed by Box–Behnken design (BBD) and mathematical model is developed using response surface methodology (RSM) on output responses like cooling rate (CR) and hardness (H), and is legitimated by confirmation tests. Analysis of variance (ANOVA) is incorporated for seeking the contributing effects and significance of the parameters. Optimal solution achieved after DGA, when P is 350.956 W, V is 12.371 mm/s, E is 49.475 J/mm2, CR is −3,146,515.795 K/s and H is 395.097 HV, and combined overall desirability is 0.838. Optimization is additionally enhanced by 20.049% of CR and 0.229% of H when evaluated with DGA.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

References

M. Younas, S.H.I. Jaffery, M. Khan et al., Multi-objective optimization for sustainable turning Ti6Al4V alloy using grey relational analysis (GRA) based on analytic hierarchy process (AHP). Int. J. Adv. Manuf. Technol. 105, 1175–1188 (2019)

M.A. Khan, S.H.I. Jaffery, M. Khan et al., Multi-objective optimization of turning titanium-based alloy Ti-6Al-4V under dry, wet, and cryogenic conditions using gray relational analysis (GRA). Int. J. Adv. Manuf. Technol. 106, 3897–3911 (2020)

R.N. Yadav, A hybrid approach of Taguchi-Response Surface Methodology for modeling and optimization of Duplex Turning process. Measurement 100, 131–138 (2017). https://doi.org/10.1016/j.measurement.2016.12.060

A. Kumar, V. Kumar, J. Kumar, Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process. Int. J. Adv. Manuf. Technol. 68, 2645–2668 (2013). https://doi.org/10.1007/s00170-013-4861-9

A. Kumar, V. Kumar, J. Kumar, Surface integrity and material transfer investigation of pure titanium for rough cut surface after wire electro discharge machining. Proc. IMechE Part B: J. Eng. Manuf. 228(8), 880–901 (2014)

A. Kumar, V. Kumar, J. Kumar, Surface crack density and recast layer thickness analysis in WEDM process through response surface methodology. Mach. Sci. Technol. Int. J. 20(2), 201–230 (2016)

K. Ananthakumar, D. Rajamani, E. Balasubramanian, D.J. Paulo, Measurement and optimization of multi-response characteristics in plasma arc cutting of Monel 400TM using RSM and TOPSIS. Measurement 135, 725–737 (2019). https://doi.org/10.1016/j.measurement.2018.12.010

N. Li, J.Y. Sheikh-Ahmad, A. El-Sinawi, V. Krishnaraj, Multi-objective optimization of the trimming operation of CFRPs using sensor-fused neural networks and TOPSIS. Measurement 132, 252–262 (2019). https://doi.org/10.1016/j.measurement.2018.09.057

T. Yu, L. Yang, Yu. Zhao, J. Sun, B. Li, Experimental research and multi-response multi-parameter optimization of laser Experimental research and multi-response multi-parameter optimization of laser cladding Fe313. Opt. Laser Technol. 108, 321–332 (2018). https://doi.org/10.1016/j.optlastec.2018.06.030

J. Jin, S. Zhou, Y. Zhao, Q. Zhang, X. Wang, W. Li, D. Chen, L. Zhang, Refined microstructure and enhanced wear resistance of titanium matrix composites produced by selective laser melting. Opt. Laser Technol. 134, 106644 (2021). https://doi.org/10.1016/j.optlastec.2020.106644

D. Cheng, J. Zhang, T. Shi, G. Li, J. Shi, L. Lu, G. Fu, Microstructure and mechanical properties of additive manufactured Ti-6Al-4V components by annular laser metal deposition in a semi-open environment. Opt. Laser Technol. 135, 106640 (2021). https://doi.org/10.1016/j.optlastec.2020.106640

T. Chen, W. Wu, W. Li, D. Liu, Laser cladding of nanoparticle TiC ceramic powder: Effects of process parameters on the quality characteristics of the coatings and its prediction model. Opt. Laser Technol. 116, 345–355 (2019). https://doi.org/10.1016/j.optlastec.2019.03.048

I. Shivakoti, G. Kibria, B.B. Pradhan, Predictive model and parametric analysis of laser marking process on gallium nitride material using diode pumped Nd:YAG laser. Opt. Laser Technol. 115, 58–70 (2019). https://doi.org/10.1016/j.optlastec.2019.01.035

S. Datta, M.S. Raza, A.K. Das, P. Saha, D.K. Pratihar, Experimental investigations and parametric optimization of laser beam welding of NiTinol sheets by metaheuristic techniques and desirability function analysis. Opt. Laser Technol. 124, 105982 (2020). https://doi.org/10.1016/j.optlastec.2019.105982

Z. Gao, X. Shao, P. Jiang, L. Cao, Q. Zhou, C. Yue, Y. Liu, Parameters optimization of hybrid fiber laser-arc butt welding on 316L stainless steel using Kriging model and GA. Opt. Laser Technol. 83, 153–162 (2016). https://doi.org/10.1016/j.optlastec.2016.04.001

C. Kumar, M. Das, C.P. Paul, B. Singh, Experimental investigation and metallographic characterization of fiber laser beam welding of Ti-6Al-4V alloy using response surface method. Opt Lasers Eng. 95, 52–68 (2017). https://doi.org/10.1016/j.optlaseng.2017.03.013

X. Wang, H. Chen, H. Liu, P. Li, Z. Yan, C. Huang, Z. Zhao, Y. Gu, Simulation and optimization of continuous laser transmission welding between PET and titanium through FEM, RSM GA and experiments. Opt. Lasers Eng. 51(11), 1245–1254 (2013). https://doi.org/10.1016/j.optlaseng.2013.04.021

Y. Rong, Z. Zhang, G. Zhang, C. Yue, Y. Gu, Y. Huang, C. Wang, X. Shao, Parameters optimization of laser brazing in crimping butt using Taguchi and BPNN-GA. Opt. Lasers Eng. 67, 94–104 (2015). https://doi.org/10.1016/j.optlaseng.2014.10.009

A. Weisheit, S. Rittinghaus, A. Dutta, J.D. Majumdar, Studies on the effect of composition and pre-heating on microstructure and mechanical properties of direct laser clad titanium aluminide. Opt. Lasers Eng. 131, 106041 (2020). https://doi.org/10.1016/j.optlaseng.2020.106041

H.Z. Niu, S.L. Xiao, F.T. Kong, C.J. Zhang, Y.Y. Chen, Microstructure characterization and mechanical properties of TiB2/TiAl in situ composite by induction skull melting process. Mater. Sci. Eng. A. 532, 522–527 (2012). https://doi.org/10.1016/j.msea.2011.11.017

H. Attar, S. Ehtemam-Haghighi, D. Kent, X. Wu, M.S. Dargusch, Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng. A. 705, 385–393 (2017). https://doi.org/10.1016/j.msea.2017.08.103

G.J. Marshall, W.J. Young, S.M. Thompson, N. Shamsaei, S.R. Daniewicz, S. Shao, Understanding the microstructure formation of Ti-6Al-4V during direct laser deposition via in-situ thermal monitoring. J. Occup. Med. 68(3), 778–790 (2016). https://doi.org/10.1007/s11837-015-1767-z

A. Bandyopadhyay, F. Espana, V.K. Balla, S. Bose, Y. Ohgami, N.M. Davies, Influence of porosity on mechanical properties and in vivo response of Ti6Al4V implants. Acta Biomater. 6(4), 1640–1648 (2010). https://doi.org/10.1016/j.actbio.2009.11.011

C. Qiu, G.A. Ravi, C. Dance, A. Ranson, S. Dilworth, M.M. Attallah, Fabrication of large Ti–6Al–4V structures by direct laser deposition. J. Alloy. Comp. 629, 351–361 (2015). https://doi.org/10.1016/j.jallcom.2014.12.234

A.J. Sterling, B. Torries, N. Shamsaei, S.M. Thompson, D.W. Seely, Fatigue behavior and failure mechanisms of direct laser deposited Ti–6Al–4V. Mater. Sci. Eng. A. 655, 100–112 (2016). https://doi.org/10.1016/j.msea.2015.12.026

Y. Hu, F. Ning, H. Wang, W. Cong, B. Zhao, Laser engineered net shaping of quasi continuous network microstructural TiB reinforced titanium matrix bulk composites: microstructure and wear performance. Optics Laser. Technol. 99, 174–183 (2018). https://doi.org/10.1016/j.optlastec.2017.08.032

Y. Hu, W. Cong, X. Wang, Y. Li, F. Ning, H. Wang, Laser deposition-additive manufacturing of TiB-Ti composites with novel three-dimensional quasi-continuous network microstructure: effects on strengthening and toughening. Compos. B Eng. 133, 91–100 (2018). https://doi.org/10.1016/j.compositesb.2017.09.019

H. Attar, M. Bönisch, M. Calin, L.C. Zhang, K. Zhuravleva, A. Funk, S. Scudino, C. Yang, J. Eckert, Comparative study of microstructures and mechanical properties of in situ Ti–TiB composites produced by selective laser melting, powder metallurgy, and casting technologies. J. Mater. Res. 29(17), 1941–1950 (2014). https://doi.org/10.1557/jmr.2014.122

S. Bose, T. Nandi, A novel optimization algorithm on surface roughness of WEDM on titanium hybrid composite. Sādhanā. 45(1), 236 (2020). https://doi.org/10.1007/s12046-020-01472-5

S. Bose, T. Nandi, Experimental investigation of WEDM on titanium hybrid composite reinforced with boron powder: a novel approach. Eur. Phys. J. Plus. 135(11), 914 (2020). https://doi.org/10.1140/epjp/s13360-020-00904-9

S. Bose, T. Nandi, Novel approach in experimental and statistical investigations on titanium matrix composite. Bull. Mater. Sci. 44(1), 46 (2021). https://doi.org/10.1007/s12034-020-02330-0

M.H. Abidi, A.M. Al-Ahmari, U. Umer, M.S. Rasheed, Multi-objective optimization of micro-electrical discharge machining of nickel-titanium-based shape memory alloy using MOGA-II. Measurement 125, 336–349 (2018). https://doi.org/10.1016/j.measurement.2018.04.096

S.P.L. Kumar, Measurement and uncertainty analysis of surface roughness and material removal rate in micro turning operation and process parameters optimization. Measurement 140, 538–547 (2019). https://doi.org/10.1016/j.measurement.2019.04.029

S.P.L. Kumar, Experimental investigations and empirical modeling for optimization of surface roughness and machining time parameters in micro end milling using Genetic Algorithm. Measurement 124, 386–394 (2018). https://doi.org/10.1016/j.measurement.2018.04.056

C.C. Nwobi-Okoye, C.U. Uzochukwu, RSM and ANN modeling for production of Al 6351/ egg shell reinforced composite: Multi objective optimization using genetic algorithm. Mater. Today Commun. 22, 100674 (2020). https://doi.org/10.1016/j.mtcomm.2019.100674

M. Iqbal, U.A. Naeem, A. Ahmad, U. Ghani, T. Farid, Relating groundwater levels with meteorological parameters using ANN technique. Measurement 164, 108163 (2020). https://doi.org/10.1016/j.measurement.2020.108163

N. Mondal, S. Mandal, M.C. Mandal, FPA based optimization of drilling burr using regression analysis and ANN model. Measurement 152(108163), 107327 (2020). https://doi.org/10.1016/j.measurement.2019.107327

V.R. Adineh, C. Aghanajafi, G.H. Dehghan, S. Jelvani, Optimization of the operational parameters in a fast axial flow CWCO2 laser using artificial neural networks and genetic algorithms. Opt. Laser Technol. 40(8), 1000–1007 (2008). https://doi.org/10.1016/j.optlastec.2008.03.003

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Both the authors confirm and declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Bose, S., Nandi, T. Microstructural characterization and measurement of laser responses of lens developed novel titanium matrix composite. Eur. Phys. J. Plus 136, 978 (2021). https://doi.org/10.1140/epjp/s13360-021-01951-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-01951-6