Abstract

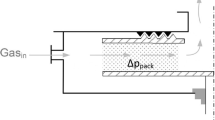

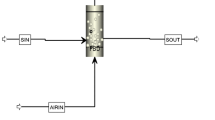

In this study, computational fluid dynamics (CFD) was used to simulate a fixed-bed distributor, investigating spherical particles in body-centered cubic (BCC) and hexagonally close-packed (HCP) structures. The bed-to-particle diameter ratio (D/dp) varied in the range of 4.158–16.65, while the range for the ratio of bed height to particle diameter (h/dp) was 5–13. The simulations were carried out for Reynolds number (Rep) in the range of 4–589, including laminar and turbulent flow regimes. To conduct validation, the numerical results were compared with our experimental data as well as seven empirical equations, where perfect match was found for both laminar and turbulent flows. Then simulations were conducted to generate the required data for an artificial neural network (ANN) to predict the velocity profile at the distributor outlet in order to save the computational CPU time. The R2, MAE and RMSE values of the neural network for predicting the fluid outlet velocity were 0.972, 0.0274 and 0.0512, respectively. The function obtained from the neural network is an efficient tool for the optimum design of fixed-bed distributors. This function could be directly used in three-dimensional fixed-bed distributor models.

Similar content being viewed by others

Abbreviations

- \(C_{1\varepsilon }\) :

-

Model parameter in the ε equation

- \(C_{2\varepsilon }\) :

-

Model parameter in the ε equation

- \(C_{3\varepsilon }\) :

-

Model parameter in the ε equation

- \(C_{\mu }\) :

-

Model parameter in the k–ε model

- \(d_{{\text{p}}}\) :

-

Particle diameter (m)

- \(D\) :

-

Bed diameter (m)

- \(G_{b}\) :

-

Turbulence kinetic energy generated by buoyancy (m2 s−2)

- \(G_{K}\) :

-

Turbulence kinetic energy generated by mean velocity gradients (m2 s−2)

- \(h\) :

-

Height of the packed bed (m)

- K :

-

Permeability (m2)

- K :

-

Turbulent kinetic energy (m2 s−2)

- \(n\) :

-

Number of data

- P :

-

Pressure (Pa)

- \({\text{Re}}_{{\text{p}}}\) :

-

Particle Reynolds number

- RH:

-

Relative humidity

- T :

-

Temperature (°C)

- W :

-

Distance from the reactor wall (m)

- X :

-

CFD coordinate direction (m)

- Y :

-

CFD coordinate direction (m)

- \(Y_{M}\) :

-

Share of noise expansion

- \(y_{m}\) :

-

Mean value of CFD results

- \(y_{{i,{\text{pred}}}}\) :

-

Predicted value

- \(y_{{i,{\text{simulate}}}}\) :

-

Simulated value

- Z :

-

CFD coordinate direction (m)

- z c :

-

Air compressibility factor

- \(\Delta P\) :

-

Pressure drop (Pa)

- \(\varepsilon\) :

-

Turbulent dispersion rate (m2 s−3)

- \(\epsilon_{m}\) :

-

Void fraction

- \(\mu_{{\text{t}}}\) :

-

Turbulent viscosity (m2 s−1)

- \(\vartheta\) :

-

Dynamic viscosity (Pa s)

- \(\rho\) :

-

Density (kg m−3)

- \(\sigma_{k}\) :

-

Model parameter

- \(\sigma_{\varepsilon }\) :

-

Model parameter

References

Y.S. Choi, S.J. Kim, D. Kim, A semi-empirical correlation for pressure drop in packed beds of spherical particles. Transp. Porous Media 75, 133–149 (2008). https://doi.org/10.1007/s11242-008-9215-y

A. Montillet, Flow through a finite packed bed of spheres: a note on the limit of applicability of the forchheimer-type equation. J. Fluids Eng. 126, 139 (2004). https://doi.org/10.1115/1.1637928

F. Depypere, J.G. Pieters, K. Dewettinck, CFD analysis of air distribution in fluidised bed equipment. Powder Technol. 145, 176–189 (2004). https://doi.org/10.1016/j.powtec.2004.06.005

P.M.G. Nejad, M.S. Hatamipour, Investigation on the removal of carbon dioxide exhausted from industrial units in a lab-scale fluidized bed reactor. Bull. Chem. React. Eng. Catal. 15, 579–590 (2020). https://doi.org/10.9767/bcrec.15.2.7882.579-590

R.A. Corrêa, L.A. Calçada, R.P. Peçanha, Development of a fluidized bed system for adsorption of phenol from aqueous solutions with commercial macroporous resins. Braz. J. Chem. Eng. 24, 15–28 (2007). https://doi.org/10.1590/S0104-66322007000100002

D.C. Sau, K.C. Biswal, Computational fluid dynamics and experimental study of the hydrodynamics of a gas–solid tapered fluidized bed. Appl. Math. Model. 35, 2265–2278 (2011). https://doi.org/10.1016/j.apm.2010.11.037

A. Kumar, G.K. Roy, Effect of different types of promoters on bed expansion in a gas–solid fluidized bed with varying distributor open areas. J. Chem. Eng. Jpn. 35, 681–686 (2002). https://doi.org/10.1252/jcej.35.681

N. Hilal, M.T. Ghannam, M.Z. Anabtawi, Effect of bed diameter, distributor and inserts on minimum fluidization velocity. Chem. Eng. Technol. 24, 161–165 (2001). https://doi.org/10.1002/1521-4125(200102)24:2%3c161::AID-CEAT161%3e3.0.CO;2-S

M. Jovanovic, Z. Grbavcic, N. Rajic, B. Obradovic, Removal of Cu(II) from aqueous solutions by using fluidized zeolite A beads: hydrodynamic and sorption studies. Chem. Eng. Sci. 117, 85–92 (2014). https://doi.org/10.1016/j.ces.2014.06.017

D.V. Kalaga, A. Dhar, S.V. Dalvi, J.B. Joshi, Particle-liquid mass transfer in solid–liquid fluidized beds. Chem. Eng. J. 245, 323–341 (2014). https://doi.org/10.1016/j.cej.2014.02.038

D. Mandal, D. Sathiyamoorthy, M. Vinjamur, Experimental investigation of heat transfer in gas–solid packed fluidized bed. Powder Technol. 246, 252–268 (2013). https://doi.org/10.1016/j.powtec.2013.04.054

M.A. Stylianou, V.J. Inglezakis, M. Loizidou, Comparison of Mn, Zn, and Cr removal in fluidized- and fixed-bed reactors by using clinoptilolite. Desalin. Water Treat. 53, 3355–3362 (2015). https://doi.org/10.1080/19443994.2014.934103

U. Vengateson, R. Mohan, Experimental and modeling study of fluidized bed granulation: effect of binder flow rate and fluidizing air velocity. Resour. Technol. 2, S124–S135 (2016). https://doi.org/10.1016/j.reffit.2016.10.003

J. Kruger, C. Toit, W. Merwe, Numerical validation of the Eisfeld and Schnitzlein pressure drop correlation for small aspect ratio packed beds, in 11th International Conference on CFD in the Minerals and Process Industries (2015), pp. 1–7

R.K. Reddy, J.B. Joshi, CFD modeling of pressure drop and drag coefficient in fixed beds: wall effects. Particuology 8, 37–43 (2010). https://doi.org/10.1016/j.partic.2009.04.010

T. Atmakidis, E.Y. Kenig, CFD-based analysis of the wall effect on the pressure drop in packed beds with moderate tube/particle diameter ratios in the laminar flow regime. Chem. Eng. J. 155, 404–410 (2009). https://doi.org/10.1016/j.cej.2009.07.057

O. Bey, G. Eigenberger, Fluid flow through catalyst filled tubes. Chem. Eng. Sci. 52, 1365–1376 (1997). https://doi.org/10.1016/S0009-2509(96)00509-X

G.T. Bolton, C.W. Hooper, R. Mann, E.H. Stitt, Flow distribution and velocity measurement in a radial flow fixed bed reactor using electrical resistance tomography. Chem. Eng. Sci. 59, 1989–1997 (2004). https://doi.org/10.1016/j.ces.2004.01.049

C. Boyer, B. Fanget, Measurement of liquid flow distribution in trickle bed reactor of large diameter with a new gamma-ray tomographic system. Chem. Eng. Sci. 57, 1079–1089 (2002). https://doi.org/10.1016/S0009-2509(01)00361-X

A.G. Dixon, Correlations for wall and particle shape effects on fixed bed bulk voidage. Can. J. Chem. Eng. 66, 705–708 (1988). https://doi.org/10.1002/cjce.5450660501

A.G. Dixon, M. Nijemeisland, CFD as a design tool for fixed-bed reactors, in Industrial and Engineering Chemistry Research (2001), pp. 5246–5254

B. Eisfeld, K. Schnitzlein, The influence of confining walls on the pressure drop in packed beds. Chem. Eng. Sci. 56, 4321–4329 (2001). https://doi.org/10.1016/S0009-2509(00)00533-9

H. Susskind, W. Becker, Pressure drop in geometrically ordered packed beds of spheres. AIChE J. 13, 1155–1159 (1967). https://doi.org/10.1002/aic.690130622

P. Sahoo, A. Sahoo, CFD simulation for hydrodynamic behaviour of fine particles in a fluidized bed. Indian J. Chem. Technol. 23, 253–261 (2016)

E.A. Foumeny, F. Benyahia, J.A.A. Castro et al., Correlations of pressure drop in packed beds taking into account the effect of confining wall. Int. J. Heat Mass Transf. 36, 536–540 (1993). https://doi.org/10.1016/0017-9310(93)80028-S

S. Damiaa, Artificial Neural Network Prediction of Hydrodynamics Characteristics of Inclined Fluidized Bed with Ring-Promoted. In: International Conference For Engineering Sciences (At Al-Mustansiriyah University/College of Engineering, Baghdad, 2014)

B. Guo, D. Li, C. Cheng et al., Simulation of biomass gasification with a hybrid neural network model. Bioresour. Technol. 76, 77–83 (2001). https://doi.org/10.1016/S0960-8524(00)00106-1

L. Cavas, Z. Karabay, H. Alyuruk et al., Thomas and artificial neural network models for the fixed-bed adsorption of methylene blue by a beach waste Posidonia oceanica (L.) dead leaves. Chem. Eng. J. 171, 557–562 (2011). https://doi.org/10.1016/j.cej.2011.04.030

S. Chowdhury, S.P. Das, Artificial neural network (ANN) modeling of adsorption of methylene blue by NaOH-modified rice husk in a fixed-bed column system. Environ. Sci. Pollut. Res. 20, 1050–1058 (2013). https://doi.org/10.1007/s11356-012-0912-2

M. Yusuf, K. Song, L. Li, Fixed bed column and artificial neural network model to predict heavy metals adsorption dynamic on surfactant decorated graphene. Colloids Surf. A Physicochem. Eng. Asp. (2020). https://doi.org/10.1016/j.colsurfa.2019.124076

D. Saha, A. Bhowal, S. Datta, Artificial neural network modeling of fixed bed biosorption using radial basis approach. Heat Mass Transf. Stoffuebertragung 46, 431–436 (2010). https://doi.org/10.1007/s00231-010-0584-8

F.E. Jones, Calculation of compressibility factor for air over the range of pressure, temperature, and relative humidity of interest in flowmeter calibration [Final Report] (1983)

M. Mourabet, A. El-Rhilassi, M. Bennani-Ziatni, A. Taitai, Comparative study of artificial neural network and response surface methodology for modelling and optimization the adsorption capacity of fluoride onto apatitic tricalcium phosphate. Univers. J. Appl. Math. 2, 84–91 (2014). https://doi.org/10.13189/ujam.2014.020202

M. Saeedan, M. Bahiraei, Effects of geometrical parameters on hydrothermal characteristics of shell-and-tube heat exchanger with helical baffles: numerical investigation, modeling and optimization. Chem. Eng. Res. Des. 96, 43–53 (2015). https://doi.org/10.1016/j.cherd.2015.02.004

G.S. Beavers, E.M. Sparrow, S.E. Rodenz, Influence of bed size on the flow characteristics and porosity of randomly packed beds of spheres. J. Appl. Mech. 40, 655–660 (1973). https://doi.org/10.1115/1.3423067

A. De Klerk, Voidage variation in packed beds at small column to particle diameter ratio. AIChE J. 49, 2022–2029 (2003)

R. Jeschar, Druckverlust in mehrkornschüttungen aus kugeln. Arch. Eisenhüttenwes 35, 91–108 (1964)

D. Handley, Momentum and heat transfer mechanism in regular shaped packing. Trans. Inst. Chem. Eng. 46, T251–T264 (1968)

D. Mehta, M.C. Hawley, Wall effect in packed columns. Ind. Eng. Chem. Process. Des. Dev. 8, 280–282 (1969). https://doi.org/10.1021/i260030a021

S. Ergun, Fluid flow through packed columns. Chem. Eng. Prog. 48, 89–94 (1952)

P.C. Carman, Fluid flow through granular beds. Trans. Inst. Chem. Eng. 15, 150–166 (1937)

N.M. Zhavoronkov, M.E. Aerov, N.N. Umnik, Hydraulic resistance and density of packing of a granular bed. J. Phys. Chem. 23, 342–361 (1949)

W. Reichelt, Zur Berechnung des Druckverlustes einphasig durchströmter Kugel- und Zylinderschüttungen. Chem. Ing. Tech. 44, 1068–1071 (1972). https://doi.org/10.1002/cite.330441806

Acknowledgements

This work was supported by vice chancellor of research of University of Isfahan under grant No. 933411137003. The sincere help of Dr. M. Mastani in language editing of this article is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohamad-Gholy-Nejad, P., Hatamipour, M.S. Experimental and numerical investigations of a fixed-bed distributor for obtaining the outlet fluid velocity profile. Eur. Phys. J. Plus 136, 599 (2021). https://doi.org/10.1140/epjp/s13360-021-01612-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-01612-8