Abstract

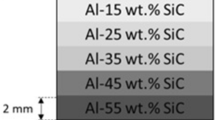

Compressive behavior of Al/SiC functionally graded composites (FGCs) was experimentally investigated. The FGC specimens are composed of ceramic (SiC) and metal (Al) constituent, varying in a predetermined configuration through the plate thickness. The compressive tests of FGCs manufactured with powder stacking hot-pressing technique were performed at different temperatures ranging from 25 to 150 °C. Al/SiC functionally graded composite specimens having three different compositions: n = 0.1, n = 0.5 and n = 1, were produced and compared to each other. It was found that the compression behavior of the FGCs was highly affected by composition variation through sample thickness. The strength of the composites decreased with the testing temperature. On the other hand, yield strength and ultimate compressive strength values increased with compositional gradient. The ultimate compressive strength of the composites reached 300 MPa. A minimum absorbed energy during the compressive tests was 25.2 × 10−3 J/mm3 and 96.9 × 10−3 J/mm3 for the test temperatures of 25 °C and 150 °C, respectively, for the compositional gradient n = 1.

Graphic abstract

Similar content being viewed by others

References

M. Koizumi, Compos. B Eng. 28, 1–4 (1997)

M. Naebe, K. Shirvanimoghaddam, Appl. Mater. Today 5, 223–245 (2016)

G. Udupa, S.S. Rao, K.V. Gangadharan, Proc. Mater. Sci. 5, 1291–1299 (2014)

L. Yan, Y. Chen, F. Liou, Addit. Manuf. 31, 100901 (2020)

M. V. Petr Lukáš, J. Vleugels, G. Anné, O. Van der Biest, Mater. Sci. Forum 571–572, 309–314 (2008)

B. Hatton, P.S. Nicholson, J. Am. Ceram. Soc. 84, 571–576 (2001)

S.U.M. Gasik, J. Therm. Stresses 23, 395–409 (2000)

J. Gottron, K.A. Harries, Q. Xu, Constr. Build. Mater. 66, 79–88 (2014)

T.H.M. Sasaki, J. Ceram. Soc. Jpn. 99, 1002–1013 (1991)

P. Malik, R. Kadoli, J. Vib. Control 24, 1171–1184 (2018)

M.M. Nemat-Alla, M.H. Ata, M.R. Bayoumi, W. Khair-Eldeen, Mater. Sci. Appl. 2, 1708–1718 (2011)

H.M.F.A.Y. Watari, R. Miyao, M. Uo, T. Kawasaki, A.T.H.M. Omori, pp. 187–190, Kluwer Academic (2001)

R. Rodrı́guez-Castro, R.C. Wetherhold, M.H. Kelestemur, Mater. Sci. Eng. A 323, 445–456 (2002)

F. Erdogan, Compos. Eng. 5, 753–770 (1995)

M. Aydin, M.K. Apalak, Mater. Sci. Eng. A 671, 107–117 (2016)

W.A. Gooch, B.H.C. Chen, M.S. Burkins, R. Palicka, J.J. Rubin, R. Ravichandran, Mater. Sci. Forum 308–311, 614–621 (1999)

P.N.S. Srinivas, R. Babu P, Balakrishna B, Mater. Res. Expr. 7, 026513 (2020)

T.P.D. Rajan, R.M. Pillai, B.C. Pai, Int. J. Cast Met. Res. 21(1–4), 214–218 (2013)

F. Ebrahimi, Advances in Functionally Graded Materials and Structures, InTechOpen (2016)

F. Milstein, B. Farber, K. Kim, L. van den Berg, W.F. Schnepple, Nucl. Instrum. Methods Phys. Res. 213, 65–76 (1983)

E. Schmid, W. Boas, Plasticity of Crystals with Special Reference to Metals. F.A. Hughes & Co. Ltd. (1935)

G. Gottstein, Physical Foundations of Materials Science (Springer, Berlin, 2004)

W.F. Hosford, Mechanical Behavior of Materials, 2nd edn. (Cambridge University Press, Cambridge, 2010)

X.Q. Xu, D.F. Watt, Acta Mater. 44, 4501–4511 (1996)

N. Shi, B. Wilner, R.J. Arsenault, Acta Metall. Mater. 40, 2841–2854 (1992)

R.J. Arsenault, L. Wang, C.R. Feng, Acta Metall. Mater. 39, 47–57 (1991)

D.D.C., Jnl. Mater, ASTM 1, 873–910 (1966)

T. Christman, A. Needleman, S. Suresh, Acta Metall. 37, 3029–3050 (1989)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aydın, M., Toker, G.P., Acar, E. et al. Processing and compressive response of Al/SiC functionally graded composites. Eur. Phys. J. Plus 135, 486 (2020). https://doi.org/10.1140/epjp/s13360-020-00501-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-020-00501-w