Abstract

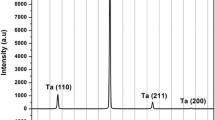

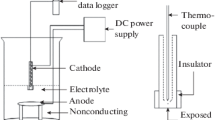

In this work, the effects of nitrogen ion implantation on the corrosion resistance and microstructure of DC magnetron sputtered tantalum-coated stainless steel were investigated. The nitrogen fluence was varied between 3–10 × 1017 ions/cm2 while the beam energy was kept constant at 30 keV. The effects of ion implantation were characterized by X-ray diffraction pattern, atomic force microscopy, and potentiodynamic corrosion test in a 0.5 MH2SO4 solution. The atomic force microscopy micrographs were quantitatively and statistically analyzed by computing the multifractal spectrum of the atomic force microscopy images. The results showed that the fluence variation strongly affected the surface roughness and formation of TaN and Ta2N phases. Increasing the nitrogen fluence up to 10 × 1017 ions/cm2 increased surface roughness. The highest corrosion resistance was obtained at 7 × 1017 ions/cm2 nitrogen fluence.

Similar content being viewed by others

References

K. Holloway, M. Fryer Peter, Cabral Cyril, Jr., J.M.E. Harper, P.J. Bailey, K.H. Kelleher, J. Appl. Phys. 71, 5433 (1992).

K.H. Min, K.C. Chun, K.B. Kim, J. Vac. Sci. Technol. B 14, 3263 (1996).

A.E. Kaloyeros, E. Eisenbraun, Annu. Rev. Mater. Sci. 30, 363 (2000).

T. Riekkinena, J. Molariusa, T. Laurilab, A. Nurmelaa, I. Sunia, J.K. Kivilahtib, Microelectron. Eng. 64, 289 (2002).

Y.X. Leng, H. Sun, P. Yang, J.Y. Chen, J. Wang, G.J. Wan, N. Huang, X.B. Tian, L.P. Wang, P.K. Chu, Thin Solid Films 398, 471 (2001).

R. Saha, J.A. Barnard, J. Cryst. Growth 174, 495 (1997).

K. Radhakrishnan, N.G. Ing, R. Gopalakrishnan, Mater. Sci. Eng. B 57, 224 (1999).

M. Wittmer, J. Appl. Phys. 53, 1007 (1982).

X. Sun, E. Kolawa, J.S. Chen, J.S. Reid, M.A. Nicolet, Thin Solid Films 236, 347 (1993).

J.C. Lin, G. Chen, C. Lee, J. Electrochem. Soc. 146, 1835 (1999).

M.H. Tsai, S.C. Sun, H.T. Chiu, C.E. Tsai, S.H. Chuang, Appl. Phys. Lett. 67, 1128 (1995).

K. Baba, R. Hatada, K. Udoh, K. Yasuda, Nucl. Instrum. Methods Phys. Res. B 127/128, 841 (1997).

Q.Y. Zhang, X.X. Mei, D.Z. Yang, F.X. Chen, T.C. Ma, Y.M. Wang, F.N. Teng, Nucl. Instrum. Methods Phys. Res. B 127/128, 664 (1997).

W. Ensinger, M. Kiuchi, M. Satou, J. Appl. Phys. 77, 6630 (1995).

D. Zhang, Q. Lin, Q. Fei, H. Zhao, G. Kang, M. Geng, Rare Metals 22, 276 (2003).

G. Reisel, R.B. Heimann, Surface Coatings Technol. 185, 215 (2004).

D. Raoufi, Physica B 405, 451 (2010).

Z.W. Chen, J.K.L. Lai, C.H. Shek, Phys. Lett. A 345, 218 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eshghi, S., Hanteh Zadeh, M., Yari, M. et al. The effect of nitrogen ion implantation on the corrosion resistance and microstructure of tantalum-coated stainless steel. Eur. Phys. J. Plus 129, 117 (2014). https://doi.org/10.1140/epjp/i2014-14117-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/i2014-14117-0