Abstract

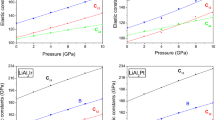

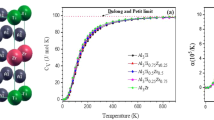

The equilibrium structural parameters, thermodynamic properties, elastic constants, and several other related properties of LiMAl2 (M = Rh, Pd, Ir and Pt) ternary intermetallic compounds have been investigated, employing the projected augmented wave pseudopotentials (PAW) approach in the framework of the density functional theory (DFT) as implemented in the Quantum Espresso code. Our findings on the lattice parameters of LiMAl2 (M = Rh, Pd, Ir and Pt) compounds agree well with the experimental ones, while our obtained results of the elastic constants are in general slightly higher than the theoretical ones reported previously in literature. Our results concerning the mechanical stability criteria indicate that all LiMAl2 (M = Rh, Pd, Ir and Pt) are mechanically stable at equilibrium, while the analyses of both Zener anisotropy factor and elastic anisotropy index show that all these compounds are highly anisotropic in their elastic properties. According to Mukhanov et al.’s (Philos. Mag. 89:2117, 2009) model, the Vickers hardness HV of LiMAl2 (M = Rh, Pd, Ir and Pt) increases gradually and almost linearly with increasing pressure. The Debye temperature θD as well as the melting point Tm of the aggregate materials are calculated using two different empirical expressions. The obtained values of θD are around 499.5 (546.4) K for LiRhAl2, 478.7 (520.6) K for LiPdAl2, 411 (451) K for LiIrAl2, and 417.3 (455.2) K for LiPtAl2 compound, respectively; while those of Tm are found to be around 1566 (1448) K for LiRhAl2, 1436 (1316) K for LiPdAl2, 1650 (1502) K for LiIrAl2, and 1615 (1489) K for LiPtAl2, respectively. Our calculated data show that the behavior of the thermodynamic properties with increasing temperatures is monotonic for all our materials of interest.

Graphical abstract

Similar content being viewed by others

Data availability statement

This manuscript has no associated data or the data will not be deposited [Authors’ comment: To the best of our knowledge, the elastic constants Cij of these materials were calculated only in the Ref. [6]. Unfortunately the authors of Ref. [6] have limited their calculation only on the Cij, and not on the other related parameters. Perhaps, the absence of the experimental data or other theoretical values of θD and Tm for LiMAl2 (M = Rh, Pd, Ir and Pt) is due to the limited works on the elastic constants Cij of these materials, because theoretically θD and Tm of the materials were usually obtained from the elastic constants Cij.]

References

R. Sharma, S.A. Dar, N. Parveen, V. Srivastava, J. Mol. Graph. Model. 94, 107463 (2020). https://doi.org/10.1016/j.jmgm.2019.107463

B. Fatima, S.S. Chouhan, N. Acharya, S.P. Sanya, Comput. Mater. Sci. 89, 205–215 (2014). https://doi.org/10.1016/j.commatsci.2014.03.008

A. Czybulka, A. Petersen, H.-U. Schuster, J. Less-Common Met. 161, 303 (1990). https://doi.org/10.1016/0022-5088(90)90041-H

L. Drews-Nicolai, G. Hohlneicher, J. Alloys Compd. 316, 1–17 (2001). https://doi.org/10.1016/S0925-8388(00)01242-1

C.M. Kube, J. Acoust. Soc. Am. 141, 1804–1811 (2017). https://doi.org/10.1121/1.4978008

C.M. Kube, Supplementary Table to Article: Iterative solution to bulk wave propagation in polycrystalline materials. See supplementary material at: https://doi.org/10.1121/1.4978008

C.M. Kube, AIP Adv. 6, 095209 (2016). https://doi.org/10.1063/1.4962996

S. Daoud, N. Bioud, L. Belagraa, N. Lebga, J. Nano- Electron. Phys., 5, 04061 (2013). https://jnep.sumdu.edu.ua/en/full_article/1138.

P. Zhou, H.R. Gong, J. Mech. Behav. Biomed. Mater. 8, 154 (2012). https://doi.org/10.1016/j.jmbbm.2011.12.001

S. Daoud, N. Bouarissa, A. Benmakhlouf, O. Allaoui, Phys. Status Solidi B 257, 1900537 (2020). https://doi.org/10.1002/pssb.201900537

P. Ravindran, L. Fast, P.A. Korzhavyi, B. Johansson, J. Wills, O. Eriksson, J. Appl. Phys. 84, 4891 (1998). https://doi.org/10.1063/1.368733

S. Daoud, N. Bioud, N. Lebga, Chinese J. Phys. 57, 165 (2019). https://doi.org/10.1016/j.cjph.2018.11.018

X. Zeng, R. Peng, Y. Yu, Z. Hu, Y. Wen, L. Song, Materials 11, 2015 (2018). https://doi.org/10.3390/ma11102015

H. Rekab-Djabri, M.M. Abdus Salam, S. Daoud, M. Drief, Y. Guermit, S. Louhibi-Fasla, J. Magnes. Alloy. 8, 1166 (2020). https://doi.org/10.1016/j.jma.2020.06.007

Z.T.Y. Liu, X. Zhou, D. Gall, S.V. Khare, Comput. Mater. Sci. 84, 365–373 (2014). https://doi.org/10.1016/j.commatsci.2013.12.038

M. Talati, S. Shinde, P.K. Jha, Physica B 348, 235–241 (2004). https://doi.org/10.1016/j.physb.2003.11.095

K. Balasubramanian, S. Khare, D. Gall, Phys. Rev. B 94, 174111 (2016). https://doi.org/10.1103/PhysRevB.94.174111

N. Bioud, X.W. Sun, S. Daoud, T. Song, Z.J. Liu, Mater. Res. Express 5, 085904 (2018). https://doi.org/10.1088/2053-1591/aad3a5

M. Aynyas, S.P. Sanyal, P.K. Jha, Phys. Status Solidi B 229, 1459–1466 (2002). https://doi.org/10.1002/1521-3951(200202)229:3%3c1459::AID-PSSB1459%3e3.0.CO;2-J

S. Baroni, A. Dal Corso, S. Gironcoli, P. Giannozzi, Rev. Med. Phys. 73, 515 (2001). https://doi.org/10.1103/RevModPhys.73.515

P.E. Blӧchl, Phys. Rev. B 50, 17953 (1994). https://doi.org/10.1103/PhysRevB.50.17953

J.P. Perdew, A. Ruzsinszky, G.I. Csonka, O.A. Vydrov, G.E. Scuseria, L.A. Constantin et al., Phys. Rev. Lett. 100, 136406 (2008). https://doi.org/10.1103/PhysRevLett.100.136406

H.J. Monkhorst, J.D. Pack, Phys. Rev. B 13, 5188 (1976). https://doi.org/10.1103/PhysRevB.13.5188

A.D. Corso, J. Phy. Condens. Matter, 28, 075401 (2016). https://dalcorso.github.io/thermo_pw/

S. Khatta, V. Kaur, S.K. Tripathi, S. Prakash, AIP Conf. Proc. 1953, 130016 (2018). https://doi.org/10.1063/1.5033160

A. Rastogi, P. Rajpoot, U.P. Verma, Bull. Mater. Sci. 42, 112 (2019). https://doi.org/10.1007/s12034-019-1758-8

B.K. Pande, A.K. Pandey, C.K. Singh, AIP Conf. Proc. 1942, 120004 (2018). https://doi.org/10.1063/1.5029044

A.R. Oganov, J.P. Brodholt, G.D. Price, in Ab initio theory of phase transitions and thermoelasticity of minerals, ed. by C.M. Gramaccioli. Energy Modelling in Minerals, vol. 4, chapter 5 (Eötvös University Press, Budapest, 2002), pp. 83–170. https://doi.org/10.1180/EMU-notes.4

S. Daoud, Eur. Phys. J. B 89, 47 (2016). https://doi.org/10.1140/epjb/e2016-60844-9

R.E. Newnham, Properties of materials: Anisotropy, Symmetry, Structure (Oxford University Press, Oxford, 2005), p. 5

S. Daoud, Mat. Res. 19, 314 (2016). https://doi.org/10.1590/1980-5373-MR-2015-0602

S. Amari, I.E. Yahiaoui, Y. Bourourou, Physica B 515, 112–117 (2015). https://doi.org/10.1016/j.physb.2017.04.010

N. Korozlu, K. Colakoglu, E. Deligöz, S. Aydin, J. Alloys Compd. 546, 157 (2013). https://doi.org/10.1016/j.jallcom.2012.08.062

S. Daoud, N. Bioud, N. Bouarissa, Mater. Sci. Semicond. Process. 31, 124 (2015). https://doi.org/10.1016/j.mssp.2014.11.024

J.J. Gilman, Electronic basis of the strength of materials (Cambridge University Press, Cambridge, 2003)

S. Jiang, L. Shao, T. Fan, J.-M. Duan, X.-T. Chen, B.-Y. Tang, Int. J. Quantum Chem. 121, e26509 (2021). https://doi.org/10.1002/qua.26509

V.A. Mukhanov, O.O. Kurakevych, V.L. Solozhenko, Philos. Mag. 89, 2117 (2009). https://doi.org/10.1080/14786430903032563

H. Algarni, O.A. Al-Hagan, N. Bouarissa, M.A. Khan, T.F. Alhuwaymel, Infrared Phys. Technol. 86, 176 (2017). https://doi.org/10.1016/j.infrared.2017.09.012

N. Bouarissa, S. Saib, M. Boucenna, F. Mezrag, Comput. Condens. Matter. 18, e00346 (2018). https://doi.org/10.1016/j.cocom.2018.e00346

S. Daoud, N. Bioud, N. Lebga, J. Cent, South Univ 21, 58–64 (2014). https://doi.org/10.1007/s11771-014-1915-6

P.K. Jha, M. Talati, Phys. Status Solidi B 239, 291 (2003). https://doi.org/10.1002/pssb.200301829

M.E. Fine, L.D. Brown, H.L. Marcus, Scr. Mater. 18, 951 (1984). https://doi.org/10.1016/0036-9748(84)90267-9

T. Özer, Can. J. Phys. 98, 357 (2020). https://doi.org/10.1139/cjp-2018-0448

T.K. Gajaria, S.D. Dabhi, P.K. Jha, Sci. Rep. 9, 5884 (2019). https://doi.org/10.1038/s41598-019-41982-9

F.B. Baghsiyahi, A. Akhtar, M. Yeganeh, Int. J. Mod. Phys. B 32, 1850207 (2018). https://doi.org/10.1142/S0217979218502077

N. Bioud, K. Kassali, X.-W. Sun, T. Song, R. Khenata, S. Bin Omran, Mater. Chem. Phys. 203, 362–373 (2018). https://doi.org/10.1016/j.matchemphys.2017.10.016

J.S. Kang, M. Li, H. Wu, H. Nguyen, Y. Hu, Appl. Phys. Lett. 115, 122103 (2019). https://doi.org/10.1063/1.5116025

N. Bioud, K. Kassali, N. Bouarissa, J. Electron Mater. 46, 2521 (2017). https://doi.org/10.1007/s11664-017-5335-x

Y. Liu, W.-C. Hu, D.-J. Li, X.-Q. Zeng, C.-S. Xu, Phys. Scr. 88, 045302 (2013). https://doi.org/10.1088/0031-8949/88/04/045302

S. Daoud, N. Bouarissa, Comput. Condens. Matter. 16, e00359 (2018). https://doi.org/10.1016/j.cocom.2018.e00359

R. Maizi, A.-G. Boudjahem, M. Boulbazine, Russ. J. Phys. Chem. A 93, 2726–2734 (2019). https://doi.org/10.1134/S0036024419130181

S. Daoud, N. Bioud, P.K. Saini, J. Magnes, Alloys 7, 335–344 (2019). https://doi.org/10.1016/j.jma.2019.01.006

Y.L. Gao, W.S. Guan, Y.J. Dong, Semiconductors 54, 1185–1190 (2020). https://doi.org/10.1134/S1063782620100115

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benamrani, A., Daoud, S. & Bouarissa, N. First principles study of structural, elastic, and thermodynamic properties of LiAl2X (X = Rh, Pd, Ir and Pt) intermetallic compounds. Eur. Phys. J. B 95, 106 (2022). https://doi.org/10.1140/epjb/s10051-022-00370-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjb/s10051-022-00370-5