Abstract

The effects of temperature and twin grain boundary position on the crack propagation mechanism of pure \(\upalpha \)-Ti were studied by molecular dynamics simulation. Under room temperature, the twin grain boundary in the intergranular crack model can guide the crack propagation path and the formation of voids intensifies the crack propagation. With the increase of temperature, the brittle–ductile transition of \(\upalpha \)-Ti occurs and the dominant factor of plastic deformation changes from grain boundary to dislocation. When the twin grain boundary is rotated \(90^{\circ }\), the stress–strain curve shows that the elastic modulus and yield strength of the transgranular crack model are better than the intergranular crack model at room temperature. During the tensile process of the transgranular model, the twin boundary improves the strength by hindering the dislocation movement. A new dislocation source is formed at both ends of the grain boundary after fracture, which improves the plasticity.

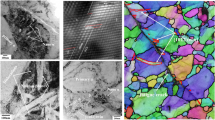

Graphic abstract

Similar content being viewed by others

Data Availability Statement

This manuscript has no associated data or the data will not be deposited. [Authors’ comment: This is a theoretical study and no experimental data.]

References

R.R. Boyer, An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 213, 103–114 (1996)

R.C. Feng, Z.Y. Rui, G.T. Zhang, C.F. Yan, X.B. Yi, Improved method of fatigue life assessment for TiAl alloys. Strength Mater. 46, 183–189 (2014)

S.M. Ohr, An electron microscope study of crack tip deformation and its impact on the dislocation theory of fracture. Mater. Sci. Eng. 72, 1–35 (1985)

D.R. Chichili, K.T. Ramesh, K.J. Hemker, The high-strain-rate response of alpha-titanium: experiments, deformation mechanisms and modeling. Acta Mater. 46, 1025–1043 (1998)

K. Tesař, A. Jäger, Electron backscatter diffraction analysis of the crack development induced by uniaxial tension in commercially pure titanium. Mater. Sci. Eng. A 616, 155–160 (2014)

B.W. Zhang, L.C. Zhou, Y. Sun, W.F. He, Y.Z. Chen, Molecular dynamics simulation of crack growth in pure titanium under uniaxial tension. Mol. Simul. 44, 1252–1260 (2018)

R.C. Feng, J.T. Lu, H.Y. Li, H. Cao, Z.Y. Rui, Effect of the microcrack inclination angle on crack propagation behavior of TiAl alloy. Strength Mater. 49, 75–82 (2017)

R.C. Feng, H. Cao, H.Y. Li, Z.Y. Rui, C.F. Yan, Effects of vacancy concentration and temperature on mechanical properties of single-crystal \(\gamma \)-TiAl based on molecular dynamics simulation. High Temp. Mater. Process. 37, 113–120 (2017)

S. Ando, K. Oyabu, K. Hirayama, M. Tsushida, H. Tonda, Crack propagation behavior in nano size HCP crystals by molecular dynamic simulation. Key Eng. Mater. 297, 280–285 (2005)

X.S. Shi, X.T. Feng, B.W. Zhang, Y. Sun, W.F. He, L.C. Zhou, Research on microstructure deformation mechanism of crack tip in titanium under tension along different orientations. Mol. Simul. 46, 440–447 (2020)

J. Cai, C.W. Mi, Q. Deng, C.Y. Zheng, Effects of crystalline orientation, twin boundary and stacking fault on the crack-tip behavior of a Mode I crack in nanocrystalline titanium. Mech. Mater. 139, 103205 (2019)

S. Ying, X.G. Zeng, The deformation mechanisms in process of crack propagation for alpha titanium with compounding microdefects. Adv. Mater. Sci. Eng. 2016, 1–13 (2016)

J. Ding, Y. Tian, L.S. Wang, X. Huang, H.R. Zheng, K. Song, X.G. Zeng, Micro-mechanism of the effect of grain size and temperature on the mechanical properties of polycrystalline TiAl. Comput. Mater. Sci. 158, 76–87 (2019)

M. Lu, F. Wang, X.G. Zeng, W.J. Chen, J.Q. Zhang, Cohesive zone modeling for crack propagation in polycrystalline NiTi alloys using molecular dynamics. Theor. Appl. Fract. Mech. 105, 102402 (2020)

L.G. Sun, X.Q. He, J.B. Wang, J. Lu, Deformation and failure mechanisms of nanotwinned copper films with a pre-existing crack. Mater. Sci. Eng. A 606, 334–345 (2014)

H. Wang, D.S. Xu, R. Yang, Atomic modelling of crack initiation on twin boundaries in \(\alpha \)-titanium under external tensile loading along various orientations. Philos. Mag. Lett. 94, 779–785 (2014)

W. Li, H. Nan, X.W. Qian, Y.J. Yin, Q. Xun, X. Shen, W. Yu, X. Feng, L.P. Zhu, J.X. Zhou, Atomistic simulation of crack propagation along \(\gamma \)-TiAl lamellar interface. IOP Conf. Ser. Mater. Sci. Eng. 529, 012042 (2019)

H. Cao, Z.Y. Rui, W.K. Chen, R.C. Feng, C.F. Yan, Crack propagation mechanism of \(\gamma \)-TiAl alloy with pre-existing twin boundary. Sci. China Technol. Sci. 62, 1605–1615 (2019)

H.X. Zong, X.D. Ding, T. Lookman, J. Li, J. Sun, Uniaxial stress-driven coupled grain boundary motion in hexagonal close-packed metals: a molecular dynamics study. Acta Mater. 82, 295–303 (2015)

P. Hirel, Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212–219 (2015)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model. Simul. Mater. Sci. Eng. 18, 2154–2162 (2010)

T. Tsuru, Y. Shibutani, T. Hirouchi, A predictive model for transferability of plastic deformation through grain boundaries. AIP Adv. 6, 015004 (2016)

S. Goel, N.H. Faisal, X.C. Luo, J.W. Yan, A. Agrawal, Nanoindentation of polysilicon and single crystal silicon: molecular dynamics simulation and experimental validation. J. Phys. D Appl. Phys. 47, 994–1004 (2014)

G.J. Ackland, Theoretical study of titanium surfaces and defects with a new many-body potential. Philos. Mag. Part A 66, 917–932 (1992)

A. Serra, D.J. Bacon, A new model for \(\{1\,0\,\bar{1}\,2\}\) twin growth in hcp metals. Philos. Mag. A 73, 333–343 (1996)

L. Chang, C.Y. Zhou, L.L. Wen, J. Li, X.H. He, Molecular dynamics study of strain rate effects on tensile behavior of single crystal titanium nanowire. Comput. Mater. Sci. 128, 348–358 (2017)

D.D. Li, W.F. Wan, L.Q. Zhu, Y. Jiang, S.Q. Shao, G.J. Yang, H.Q. Liu, D.Q. Yi, S. Cao, Q.M. Hu, Experimental and DFT characterization of interphase boundaries in titanium and the implications for \(\omega \)-assisted \(\alpha \) phase precipitation. Acta Mater. 151, 406–415 (2018)

K. Charles, Introduction to solid state physics. Am. J. Phys. 21, 547–548 (2005)

R.G. Hennig, T.J. Lenosky, D.R. Trinkle, S.P. Rudin, J.W. Wilkins, Classical potential describes martensitic phase transformations between the \(\alpha \), \(\beta \), and \(\omega \) titanium phases. Phys. Rev. B 78, 054121 (2008)

Y.B. Chen, Z. Xue, S.L. Zhang, Y. Liu, X.Y. Zhang, First principles calculations of the influence of nitrogen content on the mechanical properties of \(\alpha \)-Ti. Mater. Chem. Phys. 248, 122891 (2020)

C. Leyens, M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications (Wiley, 2003). https://doi.org/10.1002/3527602119

D.D. Li, W.F. Wang, L.Q. Zhu et al., Experimental and DFT characterization of interphase boundaries in titanium and the implications for \(\omega \)-assisted \(\alpha \) phase precipitation. Acta Mater. 151, 406–415 (2018)

J.Z. Zhang, Y.S. Zhao, R.S. Hixson et al., Thermal equations of state for titanium obtained by high pressure–temperature diffraction studies. Phys. Rev. B 78, 054119 (2008)

Y. Sun, Y. Liu, X. Chen, Z. Zhai, S. Izumi, Thermal-mechanical coupling effect on initial stage oxidation of Si (100) surface. J. Appl. Phys. 123, 135104 (2018)

Y. Sun, Z. Zhai, S. Tian, X. Chen, Effect of oxidation on crack propagation of Si nanofilm: a ReaxFF molecular dynamics simulation study. Appl. Surf. Sci. 480, 1100–1108 (2019)

Y. Wang, D. Lin, C.C. Law, Brittle-to-ductile transition temperature and its strain rate sensitivity in a two-phase titanium aluminide with near lamellar microstructure. J. Mater. Sci. 34, 3155–3159 (1999)

S.G. Song, G.T. Gray, Influence of temperature and strain rate on slip and twinning behavior of Zr. Metall. Mater. Trans. A 26, 665–675 (1995)

S. Kondo, T. Mitsuma, N. Shibata, Y. Ikuhara, Direct observation of individual dislocation interaction processes with grain boundaries. Sci. Adv. 2, 1501926 (2016)

T.C. Lee, I.M. Robertson, H.K. Birnbaum, TEM in situ deformation study of the interaction of lattice dislocations with grain boundaries in metals. Philos. Mag. A 62, 131–154 (1990)

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant Nos. 91860127 and 52075414).

Author information

Authors and Affiliations

Contributions

HW carried out the simulation and prepared the original draft. YS designed and supervised the work. BQ and XC provided scientific discussions.

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Sun, Y., Qiao, B. et al. Crack propagation mechanism of titanium nano-bicrystal: a molecular dynamics study. Eur. Phys. J. B 94, 194 (2021). https://doi.org/10.1140/epjb/s10051-021-00199-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjb/s10051-021-00199-4