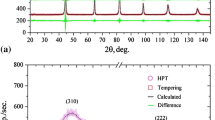

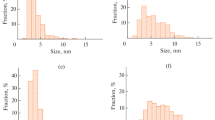

Abstract—X-ray and neutron diffraction are indispensable in the analysis of the integral characteristics of the dispersed precipitates in high-strength medium-carbon steels. Advantages and limitations of methods application have been compared by studying changes in qualitative and quantitative compositions of dispersed phases of the wear-resistant B1700 steel after quenching and tempering in the temperature range of 150–600°C. The quantity of retained austenite decreases to zero when the tempering temperature rises above 300°C. Cementite becomes noticeable in the diffraction patterns in the same temperature range. The results of the study show that neutron instruments can more reliably detect small amounts of retained austenite, while X-ray instruments provide better resolution, especially at large scattering angles.

Similar content being viewed by others

REFERENCES

Umanskii, Ya.S., Skakov, Yu.A., Ivanov, A.N., and Rastorguev, L.N., Kristallografiya, rentgenografiya i elektronnaya mikroskopiya (Crystallography, X-Ray Diffraction, and Electron Microscopy), Moscow: Metallurgiya, 1982.

Cousin, F., Small-angle neutron scattering, EPJ Web Conf., 2015, vol. 104, art. ID 01004.

Ryabov, V.V., Kniaziuk, T.V., Mikhailov, M.S., Motovilina, G.D., and Khlusova, E.I., Structure and properties of new wear-resistant steels for agricultural machine building, Inorg. Mater.: Appl. Res., 2017, vol. 8, pp. 827–836. https://doi.org/10.1134/S2075113317060120

Shvetsov, V.N., Neutron sources at the Frank Laboratory of Neutron Physics of the Joint Institute for Nuclear Research, Quantum Beam Sci., 2017, vol. 6, no. 1, pp. 1–9.

Keppler, R., Ullemeyer, K., Behrmann, J.H., and Stipp, M., Potential of full pattern fit methods for the texture analysis of geological materials: Implications from texture measurements at the recently upgraded neutron time-of-flight diffractometer SKAT, J. Appl. Crystallogr., 2014, vol. 47, pp. 1520–1534.

Nikolayev, D.I., Lychagina, T.A., Nikishin, A.V., and Yudin, V.V., Study of error distribution in measured pole figures, Solid State Phenom., 2005, vol. 105, pp. 77–82.

Lychagina, T., Nikolayev, D., Sanin, A., Tatarko, J., and Ullemeyer, K., Investigation of rail wheel steel crystallographic texture changes due to modification and thermomechanical treatment, IOP Conference Series: Materials Science and Engineering, 2015, vol. 82, art. ID 012107. https://doi.org/10.1088/1757-899X/82/1/012107

Balagurov, A.M., Beskrovnyy, A.I., Zhuravlev, V.V., Mironova, G.M., Bobrikov, I.A., Neov, D., and Sheverev, S.G., Neutron diffractometer for real-time studies of transient processes at the IBR-2 pulsed reactor, J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech., 2016, vol. 10, pp. 467–479.

Novikov, I.I., Teoriya termicheskoi obrabotki metallov (Theory of Heat Treatment of Metals), Moscow: Metallurgiya, 1986.

Zhu, C., Cerezo, A., and Smith, G.D.W., Carbide characterization in low-temperature tempered steels, Ultramicroscopy, 2009, vol. 109, pp. 545–552.

Hoyos, J., Ghilarducci, A., Salva, H., and Velez, J., Evolution of martensitic microstructure of carbon steel tempered at low temperatures, Procedia Mater. Sci., 2012, vol. 1, pp. 185–190.

Talebi, S.H., Ghasemi-Nanesa, H., Jahazi, M., and Melkonyan, H., In situ study of phase transformations during non-isothermal tempering of bainitic and martensitic microstructures, Metals, 2017, vol. 7, no. 9, art. ID 346. https://doi.org/10.3390/met7090346

Shindo, D. and Oikawa, T., Analytical Electron Microscopy for Materials Science, Tokyo: Springer, 2002. https://doi.org/10.1007/978-4-431-66988-3

Svergun, D.I. and Feigin, L.A., Rentgenovskoe i neitronnoe malouglovoe rasseyanie (X-Ray and Neutron Small-Angle Scattering), Moscow: Nauka, 1986.

Ryabov, V.V., Khlusova, E.I., Zisman, A.A., Rogozhkin, S.V., Nikitin, A.A., and Luk’yanchuk, A.A., Quantitative analysis of carbide phases in medium-carbon steel after low-temperature tempering, Metallurgist, 2019, vol. 62, pp. 926–936. https://doi.org/10.1007/s11015-019-00739-5

Hutchinson, B., Hagstrom, J., Karlsson, O., Lin-dell, D., and Tornberg, M., Microstructures and hardness of as-quenched martensites (0.1–0.5%C), Acta Mater., 2011, vol. 59, pp. 5845–5858.

Hou, Z., Babu, R.P., Hedstrom, P., and Odqvist, J., Microstructure evolution during tempering of martensitic Fe–C–Cr alloys at 700°C, J. Mater. Sci., 2018, vol. 53, pp. 6939–6950.

Gorelik, S.S., Rastorguev, L.N., and Skakov, Yu.A., Rentgenograficheskii i elektronno-opticheskii analiz (X‑Ray and Electron-Optical Analysis), Moscow: Metallurgiya, 1970.

Fedoseev, M.L., Petrov, S.N., Islamov, A.Kh., Drozdova, N.F., Lychagina, T.A., and Nikolaev, D.I., Multimethodological approach to the study of carbide particle dimensions in high-strength steel, Pis’ma Mater., 2018, vol. 8, no. 3, pp. 323–328. https://elibrary.ru/item.asp?id=35664425

Lychagina, T.A., Zisman, A.A., Yashina, E.A., and Nikolayev, D.I., Directly verifiable neutron diffraction technique to determine retained austenite in steel, Adv. Eng. Mater., 2017, vol. 20, no. 4, art. ID 1700559. https://doi.org/10.1002/adem.201700559

Grinberg, E.M., Alekseev, A.A., Budarina, A.V., and Salomatnikov, M.S., Peculiarities of martensitic structure of medium-carbon steel after low-temperature tempering, Izv. Tul’sk. Gos. Univ. Tekh. Nauki, 2015, no. 5.2, pp. 251–256.

Ivanov, Yu.F. and Kozlov, E.V., Isothermal tempering of hardened medium-carbon low-alloy steel. Transformation of a defective structure, Fund. Probl. Sovr. Materialoved., 2004, vol. 1, no. 2, pp. 21–32.

Kriška, M., Tacq, J., Van Acker, K., Seefeldt, M., and Van Petegem, S., Neutron and X-ray diffraction study of residual and internal stress evolution in pearlitic steel during cold drawing, J. Phys.: Conf. Ser., 2012, vol. 340, art. ID 012101.

ACKNOWLEDGMENTS

Experimental studies were performed on the equipment of the Center for Collective Use Composition, Structure, and Properties of Structural and Functional Materials” of the National Research Center Kurchatov Institute—CRISM Prometey.

Funding

This work was financially supported by the Ministry of Science and Higher Education of the Russian Federation, Agreement 13. TsKP.21.0014 (075-11-2021-068), unique identifier RF-2296.61321X0014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Saetova

Rights and permissions

About this article

Cite this article

Fedoseev, M.L., Petrov, S.N., Nikolaev, D.I. et al. X-ray and Neutron Diffraction Study of High-Strength Steel: Methodological Aspects. Inorg. Mater. Appl. Res. 13, 1546–1551 (2022). https://doi.org/10.1134/S2075113322060041

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322060041