Abstract

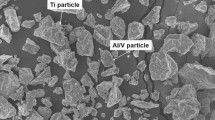

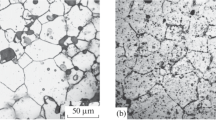

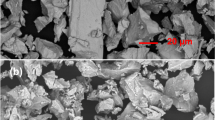

The effect of consolidation and thermal treatment on the structure, local chemical composition, and martensite transformation temperatures of the Ti28Ni50Hf22 powder alloy is studied. It is shown that, in the powder state, the alloy is characterized by an inhomogeneous distribution of Ti and Hf in the matrix, whose concentration spread may reach 27 at %. Vacuum sintering and homogenizing annealing lead to equalization of the chemical composition. During powder sintering, the spread of Ti and Hf concentrations reduces from 27 to 2 at %. Subsequent vacuum annealing at a temperature of 1000°C for 4 h for a sintered sample additionally reduces the spread of concentrations from 4 to 2 at %, while the increase in the annealing duration from 4 to 16 h does not affect the uniformity of the element distribution. It is established that, at a large inhomogeneity of the chemical composition, the differential scanning calorimetry (DSC) methods fail to record the occurrence of martensitic transformation in the melt. However, homogenization of the alloy leads to the appearance of endothermic peaks on the DSC curve upon heating, as well as to narrowing of the interval of reverse martensitic transformation.

Similar content being viewed by others

REFERENCES

Ma, J., Karaman, I., and Noebe, R.D., High temperature shape memory alloys, Int. Mater. Rev., 2010, vol. 55, pp. 257–315.

Popov, N.N., Presnyakov, D.V., Morozova, T.A., and Grishin, E.N., Study of the structure and properties of high-temperature shape-memory alloys of the Ti–Pd–Ni and Ni–Ti–Hf systems, Inorg. Mater.: Appl. Res., 2019, vol. 10, no. 4, pp. 853–864.

Karaca, H.E., Acar, E., Tobe, H., and Saghaian, S.M., NiTiHf-based shape memory alloys, Mater. Sci. Technol., 2014, vol. 30, pp. 1530–1544.

Wang, B.X., Bhagat, R., Lan, X.Z., and Dashwood, R.J., Production of Ni–35Ti–15Hf alloy via the FFC Cambridge process, J. Electrochem. Soc., 2011, vol. 158, pp. 595–602.

Yi, X., Meng, X., Cai, W., and Zhao, L., Multi-stage martensitic transformation behaviors and microstructural characteristics of Ti–Ni–Hf high temperature shape memory alloy powders, J. Alloys Compd., 2019, vol. 781, pp. 644–656.

Elahinia, M., Moghaddam, N.S., Amerinatanzi, A., Saedi, S., Toker, G.P., Karaca, H., Bigelow, G.S., and Benafam, O., Additive manufacturing of NiTiHf high temperature shape memory alloy, Scr. Mater., 2018, vol. 145, pp. 90–94.

Moshref-Javadi, M., Belbasi, M., Hossein Seyedein, S., and Taghi Salehi, M., Fabrication of (Ti,Hf)-rich NiTiHf alloy using graphitic mold and crucible, J. Mater. Sci. Technol., 2014, vol. 30, pp. 280–284.

Zhang, Z., Frenzel, J., Neuking, K., and Eggeler, G., Vacuum induction melting of ternary NiTiX (X = Cu, Fe, Hf, Zr) shape memory alloys using graphite crucibles, Mater. Trans., 2006, vol. 47, pp. 661–669.

Yang, S.Y., Kwon, Y., Choi, SW., et al., Diffusion pack cementation of hafnium powder with halide activator on Ni–Ti shape memory alloy, J. Therm. Anal. Calorim., 2018, vol. 133, pp. 5–12.

Popov, N.N., Sysoeva, T.I., Aushev, A.A., Lar’kin, V.F., and Kostyleva, A.A., Properties of a 45Ti–45Ni–10Nb shape memory alloy in the as-cast and pressed states, Russ. Metall. (Engl. Transl.), 2016, vol. 2016, no. 11, pp. 1055–1063.

Kollerov, M.Yu., Ilyin, A.A., Pol’kin, I.S., Fainbron, A.S., Gusev, D.E., and Khachin, S.V., Structural aspects of the manufacture of semiproducts made from titanium nickelide-based alloys, Russ. Metall. (Engl. Transl.), 2007, vol. 2007, no. 5, pp. 408–414.

Kasimtsev, A.V., Markova, G.V., Shuitsev, A.V., Sviridova, T.A., and Volod’ko, S.S., Changes in the structure and properties of titanium hydride-calcium nickelide powder during rotational forging, Tekhnol. Legk. Splavov, 2016, no. 3, pp. 44–52.

Markova, G.V., Kasimtsev, A.V., Volod’ko, S.S., and Alimov, I.A., The effect of cross-helical rolling on the structure and properties of TiNi powder alloy: Part 2, Tsvetn. Met., 2018, no. 12, pp. 75–81.

Kasimtsev, A.V. and Levinskii, Yu.V., Gidridno-kal’tsievye poroshki metallov, intermetallidov, tugoplavkikh soedinenii i kompozitsionnykh materialov (Calcium Hydride Powders of Metals, Intermetallic Compounds, Refractory Compounds, and Composite Materials), Moscow: Mosk. Gos. Univ. Tonk. Khim. Tekhnol., 2012.

Kasimtsev, A.V., Volod’ko, S.S., Yudin, S.N., Sviridova, T.A., and Cheverikin, V.V., Synthesis of powder alloys based on the Ti–Ni–Hf system via a calcium hydride reduction process, Inorg. Mater., 2019, vol. 55, no. 5, pp. 449–457.

Lyakishev, N.P., Diagrammy sostoyaniya dvoinyh metallicheskih sistem (State diagrams of binary metal systems), Moscow: Mashinostroenie, 1996, vol. 1.

Evirgen, A., Karaman, I., Santamarta, R., Pons, J., and Noebe, R.D., Microstructural characterization and shape memory characteristics of the Ni50.3Ti34.7Hf15 shape memory alloy, Acta Mater., 2015, vol. 83, pp. 48–60.

Umale, T., Salas, D., Tomes, B., Arroyave, R., and Karaman, I., The effects of wide range of compositional changes on the martensitic transformation characteristic of NiTiHf shape memory alloys, Scr. Mater., 2019, vol. 161, pp. 78–83.

ACKNOWLEDGMENTS

This work was supported by the Russian Foundation for Basic Research (project no. 18-03-00451 A).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by L. Mukhortova

Rights and permissions

About this article

Cite this article

Volodko, S.S., Yudin, S.N., Cheverikin, V.V. et al. Structure and Properties of Ti28Ni50Hf22 Powder Alloy. Inorg. Mater. Appl. Res. 11, 1165–1172 (2020). https://doi.org/10.1134/S2075113320050354

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320050354