Abstract—

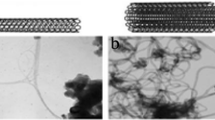

The structure, morphology, and chemical state of composites based on arrays of multiwalled carbon nanotubes and tin oxide (SnOx/MWCNT) obtained using the method of magnetron sputtering were studied using the scanning electron microscopy, transmission electron microscopy, energy-dispersive X-ray spectroscopy, and near edge X-ray absorption fine structure methods. It has been shown that porous layers with a defective structure containing Sn(II) and Sn(IV) oxides along with tin metal were formed on the surface of the MWCNT, which were transformed into crystalline Sn(IV) oxide with a tetragonal lattice at a temperature of ~550°C. The special characteristics of the oxidation and crystallization of the composite components depending on the modes of thermal treatment have been studied. It has been demonstrated that varying the modes of thermal treatment enabled nanostructured materials to be formed that differed significantly in structure, morphology, and composition. It has been hypothesized that the special aspects of the transformation of the composite structure in the process of thermal treatment were determined by the presence of contact of the MWCNT surface with atmosphere.

Similar content being viewed by others

REFERENCES

Liu, H., Zhang, W., Yu, H., et al., ACS Appl. Mater. Interfaces, 2016, vol. 8, p. 840.

Majumdar, S., Nag, P., and Devi, P., Mater. Chem. Phys., 2014, vol. 147, p. 79.

Alaf, M. and Akbulut, H., J. Power Sources, 2014, vol. 247, p. 692.

Korusenko, P.M., Nesov, S.N., and Bolotov, V.V., J. Alloys Compd., 2019, vol. 793, p. 723.

Rahmandoust, M. and Ayatollahi, M.R., Adv. Struct. Mater., 2016, vol. 39, p. 1.

Long, H., Guo, C., Wei, G., et al., Vacuum, 2019, vol. 166, p. 147.

Acauan, L., Dias, A.C., Pereira, M.B., et al., ACS Appl. Mater. Interfaces, 2016, vol. 8, p. 16444.

Nesov, S.N., Korusenko, P.M., Bolotov, V.V., et al., Kondens. Sredy Mezhfaznye Granitsy, 2018, vol. 20, p. 237.

Alexeeva, O.K. and Fateev, V.N., Int. J. Hydrogen Energy, 2016, vol. 41, p. 3373.

Kuz'michev, A.I., Magnetronnye raspylitel’nye sistemy (Magnetron Sputtering Systems), Kyiv: Avers, 2008.

Berlin, E.B. and Seidman, L.A., Poluchenie tonkikh plenok reaktivnym magnetronnym raspyleniem (Thin Films Synthesizing by means of Reactive Magnetron Sputtering), Moscow: Tekhnosfera, 2014, p. 256.

Isomura, N., Murai, T., Nomoto, T., et al., J. Synchrotron Radiat., 2017, vol. 24, p. 1.

Yang, G., Kim, B., Kim, K., et al., RSC Adv., 2015, vol. 5, p. 31861.

Li, L., Reich, S., and Robertson, J., Phys. Rev. B, 2005, vol. 72, article ID 184109.

Latham, C.D., Heggie, M.I., Alatalo, M., et al., J. Phys.: Condens. Matter, 2013, vol. 25, article ID 135403.

Korusenko, P.M., Nesov, S.N., Bolotov, V.V., et al., Phys. Solid State, 2017, vol. 59, p. 2045.

Mahajan, A., Kingon, A., Kukovecz, A., et al., Mater. Lett., 2013, vol. 90, p. 165.

Nesov, S.N., Korusenko, P.M., Bolotov, V.V., et al., Tech. Phys. Lett., 2017, vol. 43, p. 961.

Sharma, A., Varshneya, M., Shin., H.J., et al., Curr. Appl. Phys., 2016, vol. 16, p. 1342.

Manyakin, M.D., Kurganskii, S.I., Dubrovskii, O.I., et al., Mater. Sci. Semicond. Process., 2019, vol. 99, p. 28.

Manyakin, M.D., Kurganskii, S.I., Dubrovskii, O.I., et al., Comput. Mater. Sci., 2016, vol. 121, p. 119.

Fedoseeva, Yu.V., Bulusheva, L.G., Koroteev, V.O., et al., Appl. Surf. Sci., 2020, vol. 504, article ID 144357.

Fedoseeva, Yu.V., Okotrub, A.V., Bulusheva, L.G., et al., Diamond Relat. Mater., 2016, vol. 70, p. 46.

Kuznetsova, A., Popova, I., Yates, J.T., et al., J. Am. Chem. Soc., 2001, vol. 123, p. 10699.

Wang, L., Han, J., Zhu, Y., et al., J. Phys. Chem. C, 2015, vol. 119, p. 26327.

Nesov, S.N., Korusenko, P.M., Povoroznyuk, S.N., et al., Nucl. Instrum. Methods Phys. Res., Sect. B, 2017, vol. 410, p. 222.

Sivkov, V.N., Ob”edkov, A.M., Petrova, O.V., et al., Phys. Solid State, 2020, vol. 62, no. 1, p. 214.

ACKNOWLEDGMENTS

The authors are grateful to the staff of the Omsk Scientific Center of the Siberian Branch of the Russian Academy of Sciences: V.E. Roslikov for the creation of composites by the method of magnetron sputtering. The authors are also grateful to the management of the Omsk Regional Shared Equipment Center SB RAS for providing equipment for the analysis of samples by SEM and EDX methods and to the administration of the Russian–German channel of the BESSY II electron storage ring as well as D.A. Smirnov (beamline scientist at the RGL-PES station) for assistance in conducting studies by the NEXAFS method.

Funding

This work was carried out within the governmental order for Omsk Scientific Center of the Siberian Branch of the Russian Academy of Sciences (project registration number 121021600004-7).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by D. Marinin

Rights and permissions

About this article

Cite this article

Nesov, S.N., Korusenko, P.M., Bolotov, V.V. et al. Kinetics of Oxidation of Composites Based on Arrays of Multiwalled Carbon Nanotubes and Tin Oxide Obtained by the Magnetron Sputtering Method. Prot Met Phys Chem Surf 57, 735–744 (2021). https://doi.org/10.1134/S2070205121040183

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205121040183