Abstract

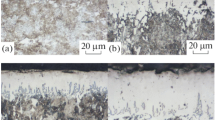

In this study, AISI 303 steels are boronized by pack boring method at 1123, 1173 and 1223 K for 2, 4 and 6 h. The morphology of the boride layers formed on the steel surfaces was examined by optical microscope. The hardness values were measured by the micro-hardness tester and the phases formed on the layer were determined by XRD method. In the XRD analysis, FeB, Fe2B, CrB and MnB phases were formed on the boride layer. Results showed that the thickness of boride layer obtained in boronized steel was increased by increasing the boring time and temperature. In addition, the thickness values of the boride layer varied depending on the chemical composition of the steel. The original hardness of AISI 303 steel was 240 HV0.05, while the boronizing process resulted in a hardness of 1897 HV0.05. The boride layer on the AISI 303 steel was formed and the thickness and growth kinetics of the layer were investigated. The activation energy (Q) of the boronized AISI 303 steel was determined as 236.502 kJ / mol.

Similar content being viewed by others

REFERENCES

Gupta, R.K. and Birbilis, N., Corros. Sci., 2015, vol. 92, pp. 1–15.

Karki, V. and Singh, M., Int. J. Mass Spectrom., 2017, vol. 421, pp. 51–60.

Peng, Y., Chen, C., Li, X., Gong, J., Jiang, Y., and Liu, Z., Surf. Coat. Technol., 2017, vol. 328, pp. 420–427.

Almuaili, F.A., McDonald, S.A., Withers, P.J., Cook, A.B., and Engelberg, D.L., Corros. Sci., 2017, vol. 125, pp. 12–19.

Sun, Y. and Bailey, R., Corros. Sci., 2018, vol. 139, pp. 197–205.

Zheng, Z.B. and Zheng, Y.G., Corros. Sci., 2016, vol. 112, pp. 657–668.

Lo, K.H., Shek, C.H., Lai, J.K.L., Mater. Sci. Eng., R, 2009, vol. 65, nos. 4–6, pp. 39–104.

Sullivan, D.O. and Cotterell, M., J. Mater. Process. Technol., 2002, vol. 124, nos. 1–2, pp. 153–159.

Wang, H., Jeong, Y., Clausen, B., Liu, Y., McCabe, R.J., Barlat, F., and Tomé, C.N., Mater. Sci. Eng., A, 2016, vol. 649, pp. 174–183.

Kim, Y.H., Kim, K.Y., and Lee, Y.D., Mater. Manuf. Processes, 2004, vol. 19, no. 1, pp. 51–59.

Ebrahimi, N., Momeni, M., Kosari, A., Zakeri, M., and Moayed, M.H., Corros. Sci., 2012, vol. 59, pp. 96–102.

Park, I.-J., Lee, S.-M., Kang, M., Lee, S., and Lee, Y.-K., J. Alloys Compd., 2015, vol. 619, pp. 205–210.

Seriacopi, V., Fukumasu, N.K., Souza, R.M., and Machado, I.F., Procedia CIRP, 2016, vol. 45, pp. 187–190.

Bejar, M.A. and Moreno, E., J. Mater. Process. Technol., 2006, vol. 173, no. 3, pp. 352–358.

Ozbek, I., Sen, S., Ipek, M., Bindal, C., Zeytin, S., and Ucisik, A.H., Vacuum, 2004, vol. 73, nos. 3–4, pp. 643–648.

Celikyurek, I., Baksan, B., Torun, O., and Gürler, R., Intermetallics, 2006, vol. 14, no. 2, pp. 136–141.

Allaouı, O., Bouaouadja, N., and Saındernan, G., Surf. Coat, Technol., 2006, vol. 201, no. 6, pp. 3475–3482.

Ozdemir, O., Omar, M.A., Usta, M., Zeytin, S., Bindal, C., and Ucisik, A.H., Vacuum, 2008, vol. 83, no. 1, pp. 175–179.

Efe, G.Ç., İpek, M., Özbek, İ., and Bindal, C., Mater. Charact., 2008, vol. 59, no. 1, pp. 23–31.

Kayali, Y., J. Balk. Tribol. Assoc., 2013, vol. 19, no. 3, pp. 340–353.

Kayali, Y., Phys. Met. Metallogr., 2013, vol. 114, no. 12, pp. 1061–1068.

Taktak, S., Mater. Des., 2007, vol. 28, no. 6, pp. 1836–1843.

Kayali, Y., Güneş, I., and Ulu, S., Vacuum, 2012, vol. 86, no. 10, pp. 1428–1434.

Ozbek, I. and Bindal, C., Vacuum, 2011, vol. 86, no. 4, pp. 391–397.

Yoon, J.H., Jee, Y.K., and Lee, S.Y., Surf. Coat. Technol., 1999, vol. 112, nos. 1–3, pp. 71–75.

Taktak, S., J. Mater. Sci., 2006, vol. 41, pp. 7590–7596.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yusuf Kayali, Ersan Mertgenç Investigation of Diffusion Kinetic Values of Boronized AISI 303 Steel by Pack Boronizing. Prot Met Phys Chem Surf 56, 151–155 (2020). https://doi.org/10.1134/S2070205120010116

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205120010116