Abstract

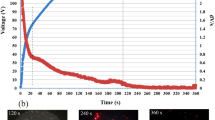

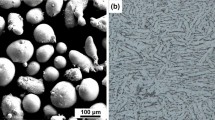

TiO2–CeO2 ceramic oxides were prepared on magnesium alloys by laser surface alloying for corrosion protection. The microstructure and composition of laser modified surfaces were characterized by scanning electron microscopy (SEM), transmission electron microscope (TEM), optical microscope (OM), energy-dispersive spectroscopy (EDS) and X-ray diffraction (XRD). The corrosion behavior was analyzed by electrochemical and salt spray tests. The effect of relative proportion between the two ceramic components on corrosion resistance of laser alloyed magnesium alloys was investigated. Results showed that there was a margin improvement in corrosion resistance after laser surface alloying with TiO2 and CeO2 at the ratio of 4 : 1 (wt %) due to the protection effect of oxides. When the content of CeO2 increased, and the ratio of TiO2 and CeO2 was 1 : 4 (wt %), defects were introduced for the poor compatibility between CeO2 and Mg matrix. The defects speed up the failure of the layer, and the corrosion resistance was even decreased compared with the as-received magnesium alloy.

Similar content being viewed by others

REFERENCES

Bala Srinivasan, P., Riekehr, S., Blawert, C., et al., Mater. Sci. Eng., A, 2009, vol. 517, p. 197.

Khalfaoui, W., Valerio, E., Masse, J.E., et al., Opt. Laser Eng., 2010, vol. 48, p. 926.

Bobzin, K., Kopp, N., Warda, T., et al., J. Therm. Spray Technol., 2013, vol. 22, p. 207.

Raman, R.K.S., Murray, S., and Brandt, M., Surf. Eng., 2007, vol. 23, p. 107.

Coy, A.E., Viejo, F., Garcia-Garcia, F.J., et al., Corros. Sci., 2010, vol. 52, p. 387.

Evans, H.E., Surf. Coat. Technol., 2011, vol. 206, p. 1512.

Phani, A.R., Gammel, F.J., Hack, T., et al., Mater. Corros., 2005, vol. 56, p. 77.

He, X.M., Liu, X.B., Wang, M.D., et al., Appl. Surf. Sci., 2011, vol. 258, p. 535.

Gao, Y.L., Wang, C.S., Yao, M., et al., Appl. Surf. Sci., 2007, vol. 253, p. 5306.

Qian, J.G., Zhang, J.X., Xu, M., et al., Rare Met. Mater. Eng., 2011, vol. 40, p. 221.

Zaharescu, M., Predoana, L., Barau, A., et al., Corros. Sci., 2009, vol. 51, p. 1998.

Zaharescu, M., Nicolescu, M., Gartner, M., et al., J. Phys.: Conf. Ser., 2012, vol. 356, p. 1.

Lokhande, C.D., Min, S.K., Jung, K.D., et al., J. Mater. Sci., 2004, vol. 39, p. 6607.

Zaharescu, M., Wittmar, A., Teodorescu, V., et al., Z. Anorg. Allg. Chem., 2009, vol. 635, p. 1915.

Shibli, S.M.A. and Chacko, F., Surf. Coat. Technol., 2011, vol. 205, p. 2931.

Cui, Z.Q., Yang, H.W., Wang, W.X, et al., J. Wuhan Univ. Technol., Mater. Sci. Ed., 2012, vol. 27, p. 1042.

Gao, Y.L., Wang, C.S., Lin, Q., et al., Surf. Coat. Technol., 2006, vol. 201, p. 2701.

Huang, K.J., Yan, L., Wang, C.S., et al., Trans. Nonferrous Met. Soc. China, 2010, vol. 20, p. 1351.

Dutta Majumdar, J., Maiwald, T., Galun, R., et al., Laser Eng., 2002, vol. 12, p. 147.

Wang, A.H. and Yue, T.M., Compos. Sci. Technol., 2001, vol. 61, p. 1549.

Chen, J.F., Zhang, Y.K., and Xu, R.J., Laser Technol., 2008, vol. 32, p. 293.

Das, M., Balla, V.K., Basu, D., et al., Scr. Mater., 2010, vol. 63, p. 438.

Zheng, B.J., Chen, X.M., and Lian, J.S., Opt. Laser Eng., 2010, vol. 48, p. 526.

Wang, C.S., Chen, Y.Z., Li, T., et al., Appl. Surf. Sci., 2009, vol. 256, p. 1609.

Yao, Z.P., Jiang, Z.H., Sun, X.T., et al., Mater. Chem. Phys., 2005, vol. 92, p. 408.

Heakal, F.E.T., Fekry, A.M., and Fatayerji, M.Z., Electrochim. Acta, 2009, vol. 54, p. 1545.

Guo, H.F. and An, M.Z., Appl. Surf. Sci., 2005, vol. 246, pp. 229–238.

Wang, L.Q., Zhou, J.S., Liang, J., et al., J. Electrochem. Soc., 2014, vol. 161, p. C20.

FUNDING

The authors acknowledge the financial supports by National Natural Science Foundation of China (Grant nos. 51505464 and 51475444).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Zhou, J., Yu, Y. et al. Microstructure and Corrosion Behavior of Laser Surface Alloyed Magnesium Alloys with TiO2-CeO2. Prot Met Phys Chem Surf 55, 729–734 (2019). https://doi.org/10.1134/S2070205119040282

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205119040282