Abstract

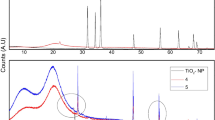

The novel poly (VAC-VeoVa-HFMA-BZMA) latex was successfully prepared via semicontinuous seeded emulsion polymerization which vinyl acetate (VAc) and vinyl ester of neodecanoic acid (VeoVa10) were main monomer, hexafluorobutyl methacrylate (HFMA) and benzyl methacrylate (BZMA) were used as functional monomer. Dodecyl benzene sulfonic acid sodium (SDBS), octylphenol polyoxyethylene ether (OP-10) and potassium persulfate (KPS) were used to be mixed emulsifier and initiator, respectively. The structure of the resultant latex is determined by Fourier transform infrared spectroscopy spectrum (FTIR). The thermal performances of latex film are studied via the thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). The average particle size of the latex is characterized by the dynamic light scattering(DLS).Water contact angle (WCA) is used to test the wetting property of the novel poly (VAC-VeoVa-HFMA-BZMA) latex film. The condition of synthesizing the latex was studied in detail. The optimum condition of preparing the novel latex is that the amount of emulsifier is 8.0% (wt %) and the mass ratio of SDBS to OP-10 is 2 : 1 and the mass ratio of main monomer VAc to VeoVa10 is 3 : 1. The amount of initiator is 0.8% and the amounts of HFMA and BZMA are 6.0 and 8.0% (wt %), respectively. Results indicate that the water resistance of the latex film and thermal stability are improved when the fluorine and BZMA monomers are added.

Similar content being viewed by others

REFERENCES

Khanjani, J., Zohuri, G.H., Gholami, M., Shojaei, B., Dalir, R.J., J. Adhes., 2014, vol. 90, p. 174.

Anderson, C.D. and Daniels E.S., Emulsion Polymerization and Latex Applications (Rapra Review Reports), Smithers Rapra Press, 2003.

Chiozza, F., Toniolo, F., and Pizzo, B., J. Appl. Polym. Sci., 2013, vol. 129, p. 1157.

Landete-Ruiz, M.D. and Martín-Martínez, J.M., Int. J. Adhes. Adhes., 2015, vol. 58, p. 34.

Eliseeva, V.I., Ivanchev, S.S., Kuchanov, S.I., and Lebedev, A.V., Emulsion Polymerization and Its Applications in Industry, Berlin: Springer, 2012.

Smith, O.W., Collins, M.J., Martin, P.S., and Bassett, D.R., Prog. Org. Coat., 1993, vol. 22, p. 19.

Aznar, A.C. and Amalvy, J.I., Lat. Am. Appl. Res., 2006, vol. 36, p. 149.

Vandezande, G.A., Smith, O.W., and Bassett, D.R., in Emulsion Polymerization and Emulsion Polymers, Lovell, P.A. and El-Aasser, M.S., Eds., London: Wiley, 1997.

Wang, R. and Wang, P.M., Constr. Build. Mater., 2011, vol. 25, p. 4210.

Wang, R., Wang, P.M., and Yao, L.J., Constr. Build. Mater., 2012, vol. 27, p. 259.

Ustinova, Y.V. and Nikiforova, T.P., Procedia Eng., 2015, vol. 111, p. 807.

Fan, F.Q., Xia, Z.B., Li, Q.Y., and Li, Z., Prog. Org. Coat., 2013, vol. 76, p. 844.

Zhang, X.W., Study on Preparation of Redispersible Polymer Powders(D), 2008.

Zhang, K.B., New Build. Mater., 2008 - 02.

Xiang, Z.H., Chem. Build. Mater., 2005, vol. 21, p. 5.

Weng, T.L., Lin, W.T., and Li, C.H., Polym. Polym. Compos., 2017, vol. 25, p. 1.

Unzue, M.A.J., Urretabtabizkaia, A.N., and Asua, J.M., J. Appl. Polym. Sci., 2000, vol. 78, p. 475.

Agirre, A., Weitzel, H.P., Hergeth, W.D., and Asua, J.M., Chem. Eng. J., 2015, vol. 266, p. 34.

Shi, J.H., Ma, Y.M., Zhang, L.Q., Xu, A.H., and Zhang, S.X., China Powder Sci. Technol., 2012, vol. 18, p. 2.

Zhu, M.Y., Qiao, W.H., Liu, H.Z., and Sun, Y.l., J. Appl. Polym. Sci., 2008, vol. 107, p. 624.

Sun, Y.l., Qiao, W.H., and Liu, H.Z., Polym. Adv. Technol., 2008, vol. 19, p. 1164.

Cheng, Y.B. and Wang, Z.G., Polymer, 2013, vol. 54, p. 3047.

Demirellia, K., Kayab, I., and CosËkuna, M., Polymer, 2001, vol. 42, p. 5181.

Zhu, H.W., The Analysis of Organic Molecular Structure Spectra, 2005, vol. 35, p. 65.

Lee, C.K., Don, T.M., Lin, D.J., Chen, C.C., and Cheng, L.P., J. Appl. Polym. Sci., 2008, vol. 109, p. 467.

Lin, X.H., Chem. Adhes., 2005, p. 27.

Liu, H.Y., Gu, J.Y., Zhang, Y.H., Tan, H.Y., and Ruan, G.F., China Wood Ind., 2009, p. 23.

Eroglu, M.S., Hazer, B., Guven, O., and Baysalts, B.M., J. Appl. Polym. Sci., 1996, vol. 60, p. 2141.

Cao, T.Y., Liu, Q.P., and Hu, J.S., Principle Properties and Application of Polymer Emulsion, 2004, vol. 175, p. 20.

FUNDING

This work has been supported by Zhejiang Provincial Natural Science Foundation of China (no. Y4100152).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lijun Chen, Shao, T., Gong, Y. et al. Synthesis and Characterization of Novel Poly (VAC-VeoVa-HFMA-BZMA) Latex via Semicontinuous Seeded Emulsion Polymerization. Prot Met Phys Chem Surf 55, 495–501 (2019). https://doi.org/10.1134/S2070205119030092

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205119030092