Abstract

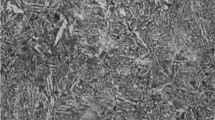

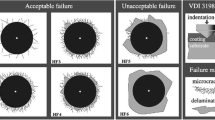

AISI D2 steel is the most commonly used cold-work tool steel in its grade. In this study, micro-structural characterization and some mechanical properties of borided AISI D2 steel samples were investigated. The boriding treatment was carried out at 900 and 1000°C for 3, 5 and 7 hours by using Ekabor 2 powder and a solid-state box boriding technique. Wear behavior of borided and non-borided steel were conducted by linear reciprocating wear test using an Al2O3 ball as the counterpart. The sliding distances and the sliding speed were remained constant at 250 m and 5 mm/s, respectively, with the loads of 10, 20 and 30 N (being applied). Microstructural characterization revealed homogeneous, dense and fine-grained structure which had predominant dual phase boride (FeB+Fe2B) layer with minor of Cr-B, Mo-B, V-B, Mn-B interstitial compounds being present as well. The thickness and hardness values of the boride layer were in the range of 46.23–126.8 µm and 2005–2227 HV0.1, respectively, depending on the process conditions. The results showed that the wear resistance improved by up to 6.7 times in comparison with non-borided AISI D2 steel. Severe plastic deformation was the effective wear mechanism in non-borided AISI D2 steel. However for the samples which were borided at 900 and 1000°C, delamination and polishing type of wear mechanisms were observed, respectively. Surface hardness and boride layer thickness had a great effect both on wear rate and wear mechanism.

Similar content being viewed by others

REFERENCES

ASM Handbook, vol. 4: Heat Treating, ASM Int., 1991.

Sista, V., Kahvecioglu, O., Eryilmaz, O.L, Erdemir, A., and Timur, S., Thin Solid Films, 2011, vol. 520, no. 5, pp. 1582–1588.

Nanesa, H.G., Touazine, H., and Jahazi, M., Int. J. Adv. Manuf. Technol., 2016, vol. 85, no. 1, pp. 881–890.

Bozali, U., Yaşar, M., Çetin, M., Çay, V.V., and Gunen, A., J. Balk. Tribol. Assoc., 2017, vol. 23, pp. 5215–5229.

ASM Handbook, vol. 4A: Steel Heat Treating Fundamentals and Processes, ASM Int., 2013.

Sudarshan, T.S. and Stiglich, J.J., Proc. 20th Int. Conference on Surface Modification Technologies, Vienna, 2006.

Ulutan, M., Yildirim, M.M., Celik, O.N., and Buytoz, S., Tribol. Lett., 2010, vol. 38, pp. 231–236.

Gunen, A., Kanca, E., Demir, M., Er, Y., Saglam, G., and Gok, M.S., Tribol. Trans., 2017, vol. 60, no. 2, pp. 267–275.

Sinha, A.K., ASM Handbook, vol. 4: Boriding (Boronizing), ASM Int., 1991, pp. 437–447.

Korzynska, K., Swirad, S., and Lubas, J., Tribol. Trans., 2012, vol. 55, pp. 325–333.

Ucar, N., Aytar, O.B., Calik, A., Nait Abdellah, Z., and Keddam, M., J. Balk. Tribol. Assoc., 2014, vol. 20, no 4, pp. 599–605.

Keddam, M., Nait Abdellah, Z., Kulka, M., and Chegroune, R., Acta Phys. Pol., A, 2015, vol. 128, no. 4, p. 745.

Wang, B., Jin, X., Xue, W., Wu, Z., Du, J., and Wu, J., Surf. Coat. Technol., 2013, vol. 232, pp. 142–149.

Gunes, I. and Ulker, S., J. Balk. Tribol. Assoc., 2016, book 4, pp. 3703–3713.

Gunen, A., Kanca, E., Cakir, H., Karakas, M.S., Gok, M.S., Kucuk, Y., and Demir, M., Surf. Coat. Technol., 2017, vol. 311, pp. 374–382.

Dinc, H., Motellabzadeh, A., Baydogan, M., and Cimenoglu, H., Acad. J. Sci., 2013, vol. 2, no. 2, pp. 385–389.

Kahvecioglu, O., Sista, V., Eryilmaz, O.L., Erdemir, A., and Timur, S., Thin Solid Films, 2011, vol. 520, no. 5, pp. 1575–1581.

Zhang, X., Liu, N., Yang, H., and Zheng, Y., Int. J. Refract. Met. Hard Mater., 2009, vol. 27, no. 3, pp. 653–658.

Ortiz-Dominguez, M., Elias-Espinosa, M., Keddam, M., Gomez-Vargas, O.A., Lewis, R., Vera-Cardenas, E.E., and Zuno-Silva, J., Indian J. Eng. Mater. Sci., 2015, vol. 22, pp. 231–243.

Roy, M., Surface Engineering for Enhanced Performance Against Wear, Wien: Springer, 2013.

Uslu, I., Comert, H., Ipek, M., Ozdemir, O., and Bindal, C., Mater. Des., 2007, vol. 28, pp. 55–61.

Allaoui, O., Bouaouadja, N., and Saindernan, G, Surf. Coat. Technol., 2006, vol. 201, pp. 3475–3482.

Cimenoglu, H., Atar, E., and Motallebzadeh, A., Wear, 2014, vol. 309, pp. 152–158.

Akshay, A., Santosh, J., Hosmani, S., and Dumbre, J., Tribol. Trans., 2004, vol. 58, no. 3, pp. 500–510.

Oliveira, C.K.N., Casteletti, L.C., Lombardi Neto, A., Totten, G.E., and Heck, S.C., Vacuum, 2010, vol. 84, pp. 792–796.

Saba, F., Kabiri, E., Khaki, J.V., and Sabzevar, M.H., Powder Technol., 2016, vol. 288, pp. 76–86.

Kyun Teak, C., Young-Kook, L., and Won Beom, L., Tribol. Int., 2015, vol. 87, pp. 82–90.

Cubillos, G.I., Olaya, J.J., Bethencourt, M., Cifredo, G., and Blanco, G., J. Therm. Spray Technol., 2013, vol. 22, no. 7, pp. 1242–1252.

Kessler, O., Herding, Th., and Hoffmann, F., Surf. Coat. Technol., 2004, vol. 182, nos. 2–3, pp. 184–191.

Caliskan, H., Measurement, 2014, vol. 55, pp. 444–451.

Ortiz-Domínguez, M., Keddam, M., Elias-Espinosa, M., Damián-Mejía, O., Flores-Rentería, M.A., Arenas-Flores, A., and Hernández-Ávila, J., Surf. Eng., 2014, vol. 30, no. 7, pp. 490–497.

Gunen, A., Ulutan, M., Gok, M.S., Kurt, B., and Orhan, N., J. Balk. Tribol. Assoc., 2014, vol. 20, no. 3, pp. 362–379.

Gunen, A., Kurt, B., Orhan, N., and Kanca, E., Prot. Met. Phys. Chem. Surf., 2014, vol. 50, no. 1, pp. 106–112.

Ulker, S., Gunes, I., and Taktak, S., Indian J. Eng. Mater. Sci., 2011, vol. 18, pp. 370–376.

Campos, I., Ramírez, G., Figueroa, U., Martínez, J., and Morales, O., Appl. Surf. Sci., 2007, vol. 253, pp. 3469–3475.

Gunes, I., J. Mater. Sci. Technol., 2013, vol. 29, pp. 662–668.

Garcia-Bustos, E., Figueroa-Guadarrama, M.A., Rodriguez-Castro, G.A., Gómez-Vargas, O.A., Gallardo-Hernandez, E.A., and Campos-Silva, I., Surf. Coat. Technol., 2013, vol. 215, pp. 241–246.

Gunes, I. and Yildiz, I., Matéria (Rio de Janeiro), 2016, vol. 21, no. 1, pp. 61–71.

Taktak, S., Mater. Des., 2007, vol. 8, pp. 1836–1843.

Sahin, S., J. Mater. Process. Technol., 2009, vol. 209, no. 4, pp. 1736–1741.

Selcuk, B., Ipek, R., and Karamis, M.B., J. Mater. Process. Technol., 2003, vol. 141, pp. 189–196.

Carrea-Espinoza, R., Figueroa-Lopez, U., Martinez-Trinidad, J., Campos-Silva, I., Hernandez-Sanchez, E., and Motallebzadeh, A., Wear, 2016, vols. 362–363, pp. 1–7.

Castillejo, F.E., Marulanda, D.M., Olaya, J.J., and Alfonso, J.E., Surf. Coat. Technol., 2014, vol. 254, pp. 104–111.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yapici, A., Aydin, S.E., Koc, V. et al. Wear Behavior of Borided AISI D2 Steel under Linear Reciprocating Sliding Conditions. Prot Met Phys Chem Surf 55, 341–351 (2019). https://doi.org/10.1134/S207020511902028X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207020511902028X