Abstract

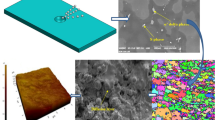

According to the principle of plasma spraying, air plasma spraying Al2O3-13 wt % TiO2/NiCrAl coating (AT13) on Q235 steel-substrate have some important disadvantages of high porosity, poor adhesive to substrate and low cohesive within the coating. Owing to such weaknesses, an enhancing densification and improving bonding of plasma-sprayed AT13 with an appropriate post air heat treatment is an effective method. On the basis of our final experimental results, post air heating treatment could improve the bonding strength and micro-structure of AT13. The AT13 shows the highest bonding strength and lowest Porosity when heating up to 560°C for 6 hours. Such performances may be because the re-crystallizing, reaction-diffusion of element diffusion and compressive stress of transitional layer. However, air heating temperature higher than 560°C led to the decline of the bonding strength. The excessive oxidizing products and compressive stress of oversized transitional layer could be contributed to the phenomenon.

Similar content being viewed by others

References

McPherson, R., in Surface Engineering Processes and Applications, Strafford, K.N., Smart, R. St.C., Sare, I., and Subramanian, C., Eds., Lancaster, PA: Technomic Publ., 1995, p. 3.

Wang, Y., Tian, W., and Yang, Y., Surf. Coat. Technol., 2007, vol. 201, p. 7746.

Tian, W., Wang, Y., and Yang, Y., Wear, 2008, vol. 265, p. 1700.

Wang, Y., Tian, W., Zhang, T., and Yang, Y., Mater. Chem. Phys., 2009, vol. 118, p. 37.

Ageorges, H. and Ctibor, P., Surf. Coat. Technol., 2008, vol. 202, p. 4362.

Wang, D., Tian, Z., Shen, L., et al., Surf. Coat. Technol., 2009, vol. 203, p. 1298.

Handbook of Thermal Spray Technology, Davis, J.R., Ed., ASM Int., 2004.

Yang, Y.C. and Chang, E., Biomaterials, 2001, vol. 22, p. 1827.

Yang, C.-W., Lee, T.-M., Lui, T.-S., and Chang, E., Mater. Sci. Eng.: C, 2006, vol. 26, p. 1395.

Karaoglanli, A.C., Dikici, H., and Kucuk, Y., Eng. Failure Anal., 2013, vol. 32, p. 16.

Jingjing, Z., Zehua, W., Pinghua, L., et al., J. Therm. Spray Technol., 2012, vol. 21, p. 782.

Li, C.L., Zhao, H.X., Matsumura, M., et al., Surf. Coat. Technol., 2000, vol. 124, p. 53.

Liu, A., Guo, M., Gao, J., and Zhao, M., Surf. Coat. Technol., 2006, vol. 201, p. 2696.

Kwon, J.-Y., Dong, K.-H., Lee, J.-H., et al., Prog. Org. Coat., 2008, vol. 61, p. 300.

Peng, Y., Zhang, C., Zhou, H., and Liu, L., Surf. Coat. Technol., 2013, vol. 218, p. 17.

Wang, B., Chang, E., Lee, T., and Yang, C., J. Biomed. Mater. Res., 1995, vol. 29, p. 1483.

Wriedt, H., J. Phase Equilib., 1991, vol. 12, p. 170.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Wang, G., Zhou, Z., Wang, Z. et al. Effect of heat treatment in air on bonding strength and micro-structure of Al2O3-13 wt % TiO2/NiCrAl coating prepared by air plasma-spray process. Prot Met Phys Chem Surf 52, 1064–1069 (2016). https://doi.org/10.1134/S2070205116060228

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205116060228