Abstract

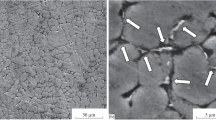

The characteristics of surface feature and microstructure of the near-surface of nickel were investigated after high current pulsed electron beam (HCPEB) irradiation. Based on a physical model, the temperature profile was simulated. The depth of heat-affected zone, the initial melting position, heating rate and quenching rate were computed. The initial coarse-grained structure on the surface was refined, of which the size is about 70 nm. The TEM observations indicate that dislocation wall, sub-dislocation wall, twin and twin boundary steps were achieved on the surface of material after HCPEB irradiation. Furthermore, huge numbers of vacancy defect clusters including dislocation loops, stacking fault tetrahedras (SFT) and voids were also formed within the sublayer of the irradiated surface. The fact that supersaturation vacancies migrated towards the surface along grain boundaries and/or various dislocation configurations led to the formation of microporous feature on the irradiated surface.

Similar content being viewed by others

References

Proskurovsky, D.I., Rotshtein, V.P., and Ozur, G.E., J. Vac. Sci. Technol. A, 1998, vol. 16, p. 2480.

Proskurovsky, D.I., Rotshtein, V.P., and Ozur, G.E., J. Vac. Sci. Technol., 2000, vol. 125, p. 49.

Grosdidier, T., Zou, J., Wu, J., et al., Sci. Technol. Adv. Mater., 2009, vol. 614, p. 99.

Zou, J.X., Grosdidier, T., Zhang, K.M., et al., Eur. Phys. J.: Appl. Phys., 2008, vol. 43, p. 343.

Hao, S.Z., Zhang, X.D., Mei, X.X., et al., Mater. Lett., 2008, vol. 62, p. 414.

Zhang, K.M., Zou, J.X., Grosdidier, T., et al., J. Alloys Compd., 2007, vol. 434, p. 707.

Guan, Q.F., Yang, P.L., Zou, H., and Zou, G.T., J. Mater. Sci., 2006, vol. 41, p. 479.

Guan, Q.F., Pan, L., Zou, H., et al., J. Mater. Sci., 2004, vol. 39, p. 6349.

Guan, Q.F., Cheng, D.Q., Qiu, D.H., et al., Acta Phys. Sin., 2009, vol. 58, p. 4846.

Guan, Q.F., Wang, X.T., Zhu, J., and Chen, K.M., ISIJ Int., 2009, vol. 49, p. 1449.

Guan, Q.F., Wang, S.Q., Cui, X.H., and Zhang, Q.Y., ISIJ Int., 2007, vol. 47, p. 1375.

Qin, Y., Dong, C., Wang, X., et al., J. Vac. Sci. Technol. A, 2003, vol. 21, p. 1934.

Klug, H.P. and Alexander, L.E., J. Am. Chem. Soc., 1974, vol. 79, p. 992.

Li, Y.S., Tao, N.R., and Lu, K., Acta Mater., 2008, vol. 56, p. 230.

Kibey, S., Liu, J.B., Johnson, D.D., and Sehitoglu, H., Acta Mater., 2007, vol. 55, p. 6843.

Hardy, G.J. and Jenkins, M.L., Philos. Mag. A, 1985, vol. 52, p. 19.

Kiritani, M., Mater. Chem. Phys., 1997, vol. 50, p. 133.

Kojima, S., Satoh, Y., Taoka, H., et al., Philos. Mag. A, 1989, vol. 59, p. 519.

Sigle, W., Jenkins, M.L., and Hutchison, J.L., Philos. Mag. Lett., 1988, vol. 57, p. 267.

Kubota, A. and Wolfer, W.G., Mater. Sci. Eng.: A, 2005, vols. 400–401, p. 362.

Wei, Q.M., Zhou, X.L., Joshi, B., et al., Adv. Mater., 2009, vol. 21, p. 1.

Pogrebnjak, A.D., Mikhaliov, A.D., Progrebnjak, N.A., et al., Phys. Lett. A, 1998, vol. 241, p. 357.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, Y., Tian, N. et al. Microstructures of pure nickel induced by high-current pulsed electron beam irradiation. Prot Met Phys Chem Surf 52, 869–875 (2016). https://doi.org/10.1134/S2070205116050269

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205116050269