Abstract

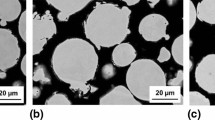

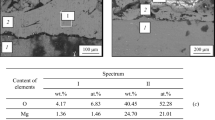

Pitting corrosion upon 7075-T6 high strength aluminum alloy, often associated with cathodic intermetallic particles decreases its fatigue life by a factor of about 6 to 8. In order to improve the corrosion resistance of this alloy, arc spray coatings of molybdenum and aluminum are applied. The open circuit potential and potentiodynamic polarization measurements made in 3.5% NaCl naturally aerated solution reveal that the molybdenum coating, which has an excellent hardness, shifts the 7075-T6 corrosion potential (E corr) to noble values and increases slightly the corrosion current density (i corr). On the contrary, when the aluminum coating alloy is applied, both E corr and i corr are shifted to better values. The increase of i corr of the alloy when molybdenum coating is applied can be attributed to the high porosity present into the coating. On the other hand, microstructure observations of the aluminum coating reveal a small porosity, which helps the formation of passive oxide film that protects the coating against a further corrosion.

Similar content being viewed by others

References

Kamp, N., Sinclair, I., and Starink, M.J., Metallurgical and Mater. Transactions A, 2002, vol. 33A, p. 1125.

Li, X.M. and Starink, M.J., Mater. Sci. and Technology, 2001, vol. 17, no. 11, p. 1324.

Chen, K.H., Liu, H.W., Zhang, Z. et. al., J. Mater. Proc. Technology, 2003, vol. 142, no. 1, p. 190.

Mondal, C. and Mukhopadhyay, A.K., Mater. Sci. Engineering A, 2005, vol. 391, no. 1–2, p. 367.

Xie, F.Y., Yan, X.Y., Ding, L. et al., Mater. Sci. Engineering A, 2003, vol. 355, no. 1–2, p. 144.

Chen, G.S., Gao, M., and Wie, R.P., Corrosion, 1996, vol. 52, no. 1, p. 8.

Wei, R.P., Liao, C.M., and Gao, M., Metall. and Mat. Trans. A, 1998, vol. 29A, p. 1153.

Puiggali, M., Zielinski, A., Olive, J.M. et al., Corrosion Sci., 1998, vol. 40, no. 4–5, p. 805.

Birbilis, N., Cavanaugh, M.K., and Buchheit, R.G., Corrosion Sci., 2006, vol. 48, p. 4202.

Huchin, J.P., Proc. of the 15th Int. Thermal Spray Conf. Nice., 1998, p. 925.

Ducos, M. and Durand, J.P., Proc. of the Int. Thermal Spray Conf. Singapore, 2001, p. 1267.

Davis, J.R., Handbook of Thermal Spray Technology, ASM International. Materials Park. OH, USA, 2004, p. 175.

Fauchais, P., Nardelle, A., and Dussoubs, B., J. Thermal Spray Technology, 2001, vol. 10, no. 1, p. 44.

Bradai, M.A., Braccini, M., Ati, A. et al., Surface and Coatings Technology, 2008, vol. 202, p. 4538.

Hwang, B., Ahn, J., and Lee, S., Surface and Coating Technology, 2005, vol. 194, no. 2–3, p. 256.

Laribi, M., Vannes, A.B., and Treheux, D., Wear., 2007, vol. 262, p. 1330.

Iordanova, I., Surtchev, M., and Forcey, K.S., Surface and Coatings Technology, 2001, vol. 139, no. 2–3, p. 118.

Campo, M., Carboneras, M., Lopez, M.D. et al., Surface and Coating Technology, 2009, vol. 203, p. 3224.

Carboneras, M., Lopez, M.D., Torres, B. et al., Corrosion Sci., 2010, vol. 52, p. 761.

Byoungchul, H., Jeehoon, A., and Sunghak, L., Surface and Coatings Technology, 2005, vol. 194, p. 256.

Gedzevicius, I. and Valiulis, A.V., J. Mater. Proc. Technology, 2006, vol. 175, p. 206.

Newbery, A.P. and Grant, P.S., J. Mater. Proc. Technology, 2006, vol. 178, p. 259.

Rodriguez, R.M.H.P., Paredes, R.S.C., Wido, S.H., and Calixto, A., Surface and Coatings Technology, 2007, vol. 202, p. 172.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Naimi, A., Yousfi, H. & Trari, M. Microstructure and corrosion resistance of molybdenum and aluminum coatings thermally sprayed on 7075-T6 aluminum alloy. Prot Met Phys Chem Surf 48, 557–562 (2012). https://doi.org/10.1134/S2070205112050061

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205112050061