Abstract

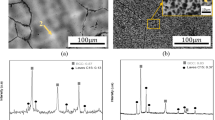

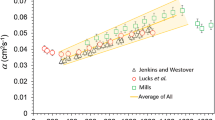

Electrodeposition of Ni-W-B alloys from plating baths containing tartrate in the absence of ammonia is studied. Detailed studies on the effects of bath temperature, pH, cathode current density and plating time have led to optimum operational conditions for obtaining satisfactory alloy deposits. The operational conditions for deposition the alloy with high hardness are; current density 30 mA cm−2, pH 6.0 and bath temperature of 60°C. The results have shown that the adherence of Ni-W-B is better than the Ni and Chromium on Cu substrate. It adheres to Cu substrates better than electrodeposited Ni and chromium. The morphology of the deposits was studied by SEM and the analysis of composition performed by EDX and inductively coupled plasma (ICP). The as-deposited alloy contained 21.66 wt % W and the highest cathode current efficiency for deposition of the alloy was about 38%. The deposit obtained under these conditions had an amorphous character with a hardness of about 800 HV, which is comparable to the hardness of chromium, occurred at a heat treatment temperature of 400°C. When heat treated up to this temperature, the initial metastable structure decomposed into fine particles of Ni4W in a nickel solid solution.

Similar content being viewed by others

References

Schell, J.D. and Rechtsteiner, M., Plating Surf. Finishing, 2000, vol. 87, p. 17.

Wynn, P.C. and Bishop, C.V., Trans. IMF, 2001, vol. 79, p. 27.

El-Sharif, M., Trans. IMF, 1997, vol. 75, p. 143.

Ibrahim, S.K., Gawne, D.T., and Watson, A., Trans. IMF, 1998, vol. 76, p. 161.

Ko, P.L. and Robertson, M.F., Wear, 2002, vol. 252, p. 880.

Eskin, S., Berkh, O., Rogalsky, G., and Zahavi, J., Plating Surf. Finishing, 1998, vol. 85, p. 79.

Mayanna, S.M., Nunichandraiah, N., and Mimani, T., J. Appl. Electrochem., 1993, vol. 23, no. 4, p. 339.

Mayanna, S.M. and Mimani, T., Surf. Coat. Technol., 1996, vol. 79, p. 246.

Wasko, A.T., Electrochemistry of Tungsten and Molybdenum, Kiev: Naukova dumka, 1977.

Brenner, A., Electrodeposition of Alloy, N.Y.: Academic Press, 1963, vol. 2, p. 589.

Maruthi, B.N., Ramesh, L., Mayanna, S.M., and Landolt, D., Plating Surf. Finishing, 1999, vol. 86, no. 3, p. 85.

Gangmin, C., Fangzu, Y., Ling, H., et al., Trans. IMF, 2001, vol. 79, no. 2, p. 81.

Wantanabe, T., New Mater. New Proces., 1985, vol. 3, p. 307.

Admon, U. and Dariel, M.P., J. Appl. Phys., 1986, vol. 59, no. 6, p. 2002.

Hosseini, M.G., Abolmaleki, M., and Sajjadi, S.A.S., Conf. Eurocorr. 2006, Mastrihgkit, Holland.

Hosseini, M.G., Abolmaleki, M., and Sajjadi, S.A.S., Conf. ISE 2007, Canada, 2007.

Hosseini, M.G., Abolmaleki, M., and Sajjadi, S.A.S., Conf. Irancorr. 2006, Trhran.

Schlo@macher, P. and Yamsaki, T., Mikrochim. Acta, 2000, vol. 132, p. 309.

Eliaz, N., Sridhar, T.M., and Gileadi, E., J. Electrochim. Acta, 2005, vol. 50, p. 2893.

Mchenry, M.E., Willard, M.A., and Laughlin, D.E., Prog. Mater. Sci., 1999, vol. 44, p. 291.

Scherrer, P., Nachr Ges Wiss Goettingen 98, 1918.

Conrad, H. and Narayan, J., Scripta Mater., 2000, vol. 42, p. 1025.

ASTM Standards D3359-87.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original

Rights and permissions

About this article

Cite this article

Hosseini, M.G., Abdolmaleki, M. & Seyed Sadjadi, S.A. Electrodeposition and mechanical properties of Ni-W-B composites from tartrate bath. Prot Met Phys Chem Surf 46, 117–122 (2010). https://doi.org/10.1134/S207020511001017X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207020511001017X