Abstract

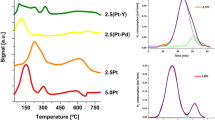

The possibility of using microchannel flow reactors to obtain the kinetic and technological parameters of the synthesis of 1-butyl-3-methylimidazolium chloride (BMIMCl) ionic liquid is demonstrated for the reaction of 1-methylimidazole (MIm) with 1-chlorobutane with no solvents. BMIMCl is produced with high selectivity and specific output in a microchannel flow reactor at temperatures of 120–180°C a contact time of 2–45 min, and a pressure of 20 bar. A positive result is obtained, due to the laminar profile of the flow and a uniform distribution of the reagents concentration over the microchannel cross section. Studying the kinetics of the process in a microchannel flow reactor reveals a shift of the reaction to the mode of diffusive inhibition at temperatures above 150°C. The kinetic data obtained for BMIMCl synthesis are used to develop ways of producing 1-ethyl-3-methylimidazolium and 1-hexyl-3-methylimidazolium chlorides (EMIMCl and HMIMCl, respectively) under the conditions of a microchannel flow reactor. The approach proposed in this work is of interest in developing flow and periodic facilities for the low-tonnage production of dialkylimidazolium, ammonium, and pyridinium salts via quaternization of the corresponding alkyl chlorides and nitrogen-containing bases.

Similar content being viewed by others

REFERENCES

Elements of the Business of Chemistry, 2017. https://www.coursehero.com/file/50199317/2017-Elements-of-the-Business-of-Chemistrypdf/. Cited July 12, 2020.

Specialty chemicals market to reach $1.79 trillion by 2025, Focus Catal., 2017, vol. 2017, no. 8. https://doi.org/10.1016/j.focat.2017.07.011

Eisberg, N., Chem. Ind., 2014, vol. 78, pp. 42–45.

Perry’s Chemical Engineers’ Handbook, Green, D.W. and Perry, R.H., Eds., New York: McGraw-Hill, 2008.

Bieringer, T., Buchholz, S., and Kockmann, N., Chem. Eng. Technol., 2013, vol. 36, no. 6, pp. 900–910.

Keil, F.J., Rev. Chem. Eng., 2018, vol. 34, no. 2, pp. 135–200.

Appel, J., Colombo, C., Dätwyler, U., Chen, Y., and Kerimoglu, N., Chimia, 2016, vol. 70, no. 9, pp. 621–627.

Wesche, M., Häberl, M., Kohnke, M., and Scholl, S., Chem. Ing. Tech., 2015, vol. 87, no. 3, pp. 203–215.

Ghaini, A., Balon-Burger, M., Bogdan, A., Krtschil, U., and Löb, P., Chem. Eng. Technol., 2015, vol. 38, no. 1, pp. 33–43.

Kashid, M.N., Renken, A., and Kiwi-Minsker, L., Microstructured Devices for Chemical Processing, Weinheim: Wiley-VCH, 2015, ch. 1, pp. 1–17.

Krtschil, U., Hofmann, C., Löb, P., Schütt, C., Schorcht, P., and Streuber, M., Green Process. Synth., 2013, vol. 2, no. 5, pp. 451–463.

Porta, R., Benaglia, M., and Puglisi, A., Org. Process Res. Dev., 2016, vol. 20, no. 1, pp. 2–25.

Reintjens, R. and de Vries, A.H.M., Chem. Eng., 2016, vol. 123, p. 40.

Suryawanshi, P.L., Gumfekar, S.P., Bhanvase, B.A., Sonawane, S.H., and Pimplapure, M.S., Chem. Eng. Sci., 2018, vol. 189, no. 2, pp. 431–448.

Protasova, L.N., Bulut, M., Ormerod, D., Buekenhoudt, A., Berton, J., and Stevens, C.V., Org. Process Res. Dev., 2013, vol. 17, no. 5, pp. 760–791.

Lau, W.N., Yeung, K.L., and Martin-Aranda, R., Microporous Mesoporous Mater., 2008, vol. 115, nos. 1–2, pp. 156–163.

Wan, Y.S.S., Gavriilidis, A., and Yeung, K.L., Chem. Eng. Res. Des., 2003, vol. 81, no. 7, pp. 753–759.

Horny, C., Kiwi-Minsker, L., and Renken, A., Chem. Eng. J., 2004, vol. 101, nos. 1–3, pp. 3–9.

Karim, A., Bravo, J., and Datye, A., Appl. Catal., A, 2005, vol. 282, nos. 1–2, pp. 101–109.

Bellos, G.D. and Papayannakos, N.G., Catal. Today, 2003, vols. 79–80, pp. 349–355.

Andreev, D.V., Sergeev, E.E., Gribovskii, A.G., Makarshin, L.L., Prikhod’ko, S.A., Adonin, N.Yu., Pai, Z.P., and Parmon, V.N., Chem. Eng. J., 2017, vol. 330, pp. 899–905.

García-Verdugo, E., Altava, B., Burguete, M.I., Lozano, P., and Luis, S.V., Green Chem., 2015, vol. 17, no. 5, pp. 2693–2713.

Hallett, J.P. and Welton, T., Chem. Rev., 2011, vol. 111, no. 5, pp. 3508–3576.

Sawant, A.D., Raut, D.G., Darvatkar, N.B., and Salunkhe, M.M., Green Chem. Lett. Rev., 2011, vol. 4, no. 1, pp. 41–54.

Hu, S., Wang, A., Löwe, H., Li, X., Wang, Y., Li, C., and Yang, D., Chem. Eng. J., 2010, vol. 162, no. 1, pp. 350–354.

Löwe, H., Axinte, R.D., Breuch, D., Hofmann, C., Petersen, J.H., Pommersheim, R., and Wang, A., Chem. Eng. J., 2010, vol. 163, no. 3, pp. 429–437.

Zhang, J., Wang, Y.J., and Hu, S.Z., Asian J. Chem., 2014, vol. 26, no. 8, pp. 2369–2372.

Bubalo, M.C., Sabotin, I., Radoš, I., Valentinčič, J., Bosiljkov, T., Brnčić, M., and Žnidaršič-Plazl, P., Green Process. Synth., 2013, vol. 2, no. 6, pp. 579–590.

Seddon, K.R., J. Chem. Technol. Biotechnol., 1997, vol. 68, no. 4, pp. 351–356.

Böwing A.G. and Jess, A., Green Chem., 2005, vol. 7, no. 4, pp. 230–235.

Burrell, A.K., Del Sesto, R.E., Baker, S.N., McCleskey, T.M., and Baker, G.A., Green Chem., 2007, vol. 9, no. 5, pp. 449–454.

Kärkkäinen, J., Asikkala, J., Laitenen, R.S., and Lajunen, M.K., Z. Naturforsch., 2004, vol. 59b, pp. 763–770.

Zhou, Z., Wang, T., and Xing, H., Ind. Eng. Chem. Res., 2006, vol. 45, no. 2, pp. 525–529.

Verevkin, S.P., Zaitsau, D.H., Emel’yanenko, V.N., Paulechka, Y.U., Blokhin, A.V., Bazyleva, A.B., and Kabo, G.J., J. Phys. Chem. B, 2011, vol. 115, no. 15, pp. 4404–4411.

Stridh, G. and Sunner, S., J. Chem. Thermodyn., 1975, vol. 7, no. 2, pp. 161–168.

Shehatta, I., Thermochim. Acta, 1993, vol. 213, pp. 1–10.

Verevkin, S.P., Zaitsau, D.H., Emel’yanenko, V.N., Ralys, R.V., Yermalayeu, A.V., and Schick, C., Thermochim. Acta, 2013, vol. 562, pp. 84–95.

Raja, L.L., Kee, R.J., Deutschmann, O., Warnatz, J., and Schmidt, L.D., Catal. Today, 2000, vol. 59, nos. 1–2, pp. 47–60.

Scott, F.H., Elements of Chemical Reaction Engineering, Boston, MA: Prentice Hall, 2016.

Bogdanov, M.G. and Svinyarov, I., Processes, 2017, vol. 5, no. 4, pp. 52–62.

Firaha, D.S. and Paulechka, Y.U., Int. J. Chem. Kinet., 2013, vol. 45, no. 12, pp. 771–779.

Clough, M., Griffith, J., Sulaiman, M.R., Corbett, P., and Welton, T., Alkylation of 1-methylimidazole with 1-chlorobutane; the ionic liquid 1-butyl-3-methylimidazolium chloride, ChemSpider SyntheticPages, Royal Society of Chemistry, http://cssp.chemspider.com/747. Cited July 12, 2020.

Dupont, J., Consorti, C.S., Suarez, P.A.Z., de Souza, R.F., Fulmer, S.L., Richardson, D.P., Smith, T.E., and Wolff, S., Org. Synth., 2002, vol. 79, pp. 236–243.

Chiappe, C., Mezzetta, A., Pomelli, C.S., Puccini, M., and Seggiani, M., Org. Process Res. Dev., 2016, vol. 20, no. 12, pp. 2080–2084.

Gonzalez, M.A. and Ciszewski, J.T., Org. Process Res. Dev., 2009, vol. 13, no. 1, pp. 64–66.

Funding

This work was performed as part of project no. 0303-2019-0007 (AAAA-A17-117041710082-8) for the Boreskov Institute of Catalysis, Siberian Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state they have no conflicts of interest to declare.

Additional information

Translated by P. Vlasov

Rights and permissions

About this article

Cite this article

Klimenko, A.S., Andreev, D.V., Prikhod’ko, S.A. et al. Using a Microchannel Reactor to Optimize the Production of 1-Alkyl-3-Methylimidazolium Chlorides. Catal. Ind. 12, 207–215 (2020). https://doi.org/10.1134/S2070050420030071

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050420030071