Abstract

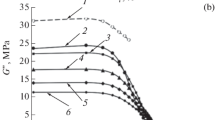

To evaluate the effectiveness of asphalt–concrete powder modifiers (PMs) prepared via high-temperature shear-induced grinding of waste tire rubber or its cogrinding with thermoplastic elastomers and employed according to the Russian dry process, regulatory requirements to the model binder were specified. The process of evaluation of the optimal concentration of PMs in model binder (MB), which improves the rheological characteristics in the entire temperature range in service of road pavement, is shown. It is determined that fatigue tests of MBs are decisive in the determination of optimal concentration of PMs. A decrease in the concentration of PM below optimal could worsen the stability of MB to the formation of fatigue cracks as compared to initial bitumen. The suggested set of tests can be recommended for the choice of the composition and evaluation of the quality of rubber–bitumen and polymer–bitumen binders.

Similar content being viewed by others

REFERENCES

A. A. Berlin, V. G. Nikolskiy, I. A. Krasotkina, T. V. Dudareva, A. V. Sorokin, V. A Lobachev., S. I. Dubina, and M. Yu. Sinkevich, “Problems of effectiveness evaluation of modifiers introduced into asphalt concrete mixtures according to “Russian dry process,” Polym. Sci., Ser. D 14, 421–426 (2021).

A A. A. Berlin, V. G. Nikolskiy, I. A. Krasotkina, T. V. Dudareva, V. N. Gorbatova, A. V. Sorokin, V. A. Lobachev, S. I. Dubina, and M. Yu. Sinkevich, “Rubber and rubber-polymer modifiers of asphalt concrete mixtures produced by method of high-temperature shear grinding. Part 2. Methodology for effectiveness evaluation of modifiers,” Polym. Sci., Ser. D 14, 568–574 (2021).

M. D. Elwardany, J. P. Planche, and G. King, “Universal and practical approach to evaluate asphalt binder resistance to thermally-induced surface damage,” Constr. Build. Mater. 255, 119331 (2020).

D. Christensen, Transportation Research Circular E-C241 “Past, Present, and Future of Asphalt Binder Rheological Parameters” (Transportation Research Board, Washington, DC, 2019).

P. Tavasotti, R. Aurilio, D. Zhao, and H. Baaj, “Investigating the nonlinear behavior of neat and modified binders through large amplitude oscillatory (LAOS) shear testing,” in Proc. of RILEM International Symposium on Bituminous Materials (2020) (preprint).

M. Aurilio, P. Tavassoti, M. D. Elwardany, and H. Baaj, “Comparing the ability of different tests and rheological indices to evaluate the cracking resistance of polymer modified asphalt binders,” Proc. Can. Tech. Asphalt Assoc., 254–252 (2020).

Use of the Delta Tc Parameter to Characterize Asphalt Binder Behavior (Asphalt Institute, Lexington, KY, 2019).

L. G. Cucalon, F. Kaseer, E. Arámbula-Mercado, A. E. Martin, N. Morian, S. Pournoman, and E. Hajj, “The crossover temperature: Significance and application towards engineering balanced recycled binder blends,” Road Mater. Pavement Des. 20 (6), 1391–1412 (2019).

H. Chen, Y. Zhang, and H. Bahia, “The role of binders in cracking resistance of mixtures measured with the IFIT procedure,” Proc. Can. Tech. Asphalt Assoc. 64, 401–421 (2019).

I. Bessa, K. Vasconcelos, V. F. T. Castelo Branco, and L. Bernucci, “Fatigue resistance of asphalt binders and the correlation with asphalt mixture behaviour,” Road Mater. Pavement Des. 20, 695–709 (2019).

V. N. Gorbatova, I. V. Gordeeva, T. V. Dudareva, I. A. Krasotkina, V. G. Nikolsky, and Yu. A. Naumova, “Rheological properties of bitumen with powder rubber modifier obtained by high-temperature shear grinding,” Proc. EECE 2020. Lecture Notes in Civil Engineering 150, 475–485 (2021). https://doi.org/10.1007/978-3-030-72404-7_46

M. Farrar, C. Sui, S. Salmans, and Qian Qin, Determining the Low-Temperature Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR): Fundamental Properties of Asphalts and Modified Asphalts III Product: FP 08 (Western Research Institute, Laramie, WY, 2015).

C. M. Jonson, PhD Thesis (University of Wisconsin-Madison, Madison, 2011).

V. N. Gorbatova, I. V. Gordeeva, T. V. Dudareva, I. A. Krasotkina, and V. G. Nikolsky, “Composite bitumen binders based on an active powder of discretely devulcanized tire rubber,” Key Eng. Mater. 869, 146–151 (2020).

GOST (State Standard) R 58400.10–2019. Automobile Roads for General Use. Oil Bituminous Binders. AASHTO T315-20 Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR).

GOST (State Standard) R 58400.6–2019. Automobile Roads for General Use. Oil Bituminous Binders. AASHTO T 350-19 Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR).

GOST (State Standard) R 58400.7–2019. Automobile Roads for General Use. Oil Bituminous Binders. AASHTO TP 101-12 Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep, 2018.

GOST (State Standard) R 58400.9–2019. Automobile Roads for General Use. Oil Bituminous Binders. Method for Determining the Low-Temperature Properties Using a Dynamic Shear Rheometer (DSR).

Comprehensive Pavement Design Manual (New York State Department of Transportation, 2019), sec. 6.2.6.

GOST (State Standard) R 58400.2–2019. Automobile Roads for General Use. Oil Bituminous Binders. Technical Requirements Accounting the Levels of Operational Traffic Loads.

GOST (State Standard) R 58400.1–2019. Automobile Roads for General Use. Oil Bituminous Binders. The Procedure for Determining the Brand Taking into Account the Temperature Range of Operation.

I. V. Gordeeva, Yu. A. Naumova, V. G. Nikolsky, I. A. Krasotkina, and T. V. Dudareva, “Analysis of flow curves of modified bitumen composites,” Polym. Sci., Ser. D 13, 151–156 (2020).

A. A. Berlin, T. V. Dudareva, I. A. Krasotkina, and V. G. Nikol’skii, “Recycling of waste rubber and the active powder of discrete devulcanized rubber,” Polym. Sci., Ser. D 3, 323–2329 (2018).

Funding

Thos work was supported by a subsidy allocated to the Federal Research Center of Chemical Physics of the Russian Academy of Sciences in the framework of a state assignment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Muravev

Rights and permissions

About this article

Cite this article

Berlin, A.A., Nikol’skii, V.G., Krasotkina, I.A. et al. Rubber and Rubber–Polymer Modifiers of Asphalt–Concrete Mixes Prepared by High-Temperature Shear-Induced Grinding. Part 3. Evaluation of Effectiveness of Modification. Polym. Sci. Ser. D 15, 71–78 (2022). https://doi.org/10.1134/S199542122201004X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S199542122201004X