Abstract

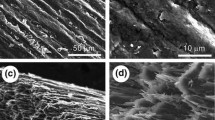

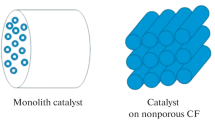

An important distinctive feature during the preparation of products from an Ipresscon® carbon–carbon composite is the formation of carbon fibers from Oxypan® oxidized polyacrylonitrile fibers. The polymer fibers are transformed into carbon ones with gas evolution and stresses during high-temperature heat treatment under pressure. A model of a porous skeleton, in which pores are replaced with disk-shaped gaps, is proposed. High-temperature experimental data and theoretical calculations resulting in Ipresscon® high-quality products are reported.

Similar content being viewed by others

REFERENCES

Jiewen Li, Shouquan Yu, Min Ge, Xi Wei, et al., “Fabrication and characterization of biomorphic cellular C/SiC–ZrC composite ceramics from wood,” Ceram. Int. 41 (6), 7853–7859 (2015).

Dong J. Lee, Jong J. Jang, Hee S. Park, and Yun C. Kim, “Fabrication of biomorphic SiC composites using wood preforms with different structures,” Ceram. Int. 38 (4), 3089–3095 (2012).

B. K. Kardashev, T. S. Orlova, B. I. Smirnov, et al., “Young’s modulus and internal friction of the SiC/Si biomorphic composite based on the sapele wood precursor,” Phys. Solid State 51 (4), 750–753 (2009).

J. Ramirez-Rico, M. Singh, D. Zhu, and J. Martinez-Fernandez, “High-temperature thermal conductivity of biomorphic SiC/Si ceramics,” J. Mater. Sci. 52 (17), 10 038–10 046 (2017).

E. A. Bogachev, “High-temperature structural materials with a minimum structural cell,” Kompoz. Nanostrukt. 9 (1), 12–23 (2017).

E. A. Bogachev, A. B. Elakov, A. P. Beloglazov, Yu. A. Denisov, and A. N. Timofeev, RF Patent No. RU2620810C1 (May 29, 2017).

S. N. Gladkikh and M. G. Mokrushin, “Heat- and high-temperature-resistant adhesives for joining carbon and ceramic materials,” Polym. Sci., Ser. D 3 (4), 258–262 (2010).

V. A. Nelyub and A. A. Berlin, “A study of the chemical structure of the surface of carbon fibers before and after oxidation,” Polym. Sci., Ser. D 8 (3), 175–180 (2015).

D. V. Grashchenkov, N. E. Shchegoleva, E. P. Simonenko, and G. V. Ermakova, “High-temperature ceramic composites stable during long-term use at temperatures up to 2000°C with a multilevel complex protection system,” Polym. Sci., Ser. D 5 (3), 205–207 (2012).

E. V. Kogan, Yu. M. Volfkovich, V. V. Kulakov, et al., “Porous structure of carbon-carbon friction composites studied by gas adsorption and standart contact porosimetry techniques,” Inorg. Mater. 48, 676–679 (2012).

Yu. M. Volfkovich, A. N. Filippov, and V. S. Bagotsky, Structural Properties of Porous Materials and Powders Used in Different Fields of Science and Technology (Springer-Verlag, London, 2014).

Kek-Kiong Tio, Chang Yu Liu, and Kok Chuan Toh, “Thermal analysis of micro heat pipes using a porous medium model,” Heat Mass Transfer 36 (1), 21–28 (2000).

N. P. Szabo, K. Kormos, and M. Dobroka, “Evaluation of hydraulic conductivity in shallow groundwater formations: A comparative study of the Csókás and Kozeny–Carman Model,” Acta Geod. Geophys. 50 (4), 461–477 (2015).

R. A. Turusov and A. Rouabhi, “Capillary model of a wound thick-walled cylinder,” Mech. Compos. Mater. 50 (1), 65–70 (2014).

V. Ya. Varshavskii, Carbon Fibers, 2nd ed. (Khimiya, Moscow, 2007) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Tulyabaev

Rights and permissions

About this article

Cite this article

Turusov, R.A., Bogachev, E.A., Sergeev, A.Y. et al. Simulation of the Gas Evolution Process and Filtration during Preparation of Ipresscon® Carbon Frames. Polym. Sci. Ser. D 12, 211–217 (2019). https://doi.org/10.1134/S1995421219020242

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421219020242