Abstract

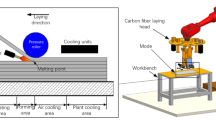

The permittivity coefficient, volume, and porosity of an elementary cell of fabric filler have been calculated. Two types of fabric structures have been considered using the example of carbon fabric: standard, in which filament yarn is cylindrical, and spread, it which it has a rectangular shape. A reflector of a mirror space antenna has been considered characterized by the presence of doubly curved surfaces is used as the object of study. Modeling of the kinetics of impregnation of reflector for two types of fabric structures has been carried out using the RAM–RTM program. In the work, the effect of the network angle on the duration of impregnation process has also been investigated. Based on the results of calculation, reflector samples have been made and their quality has been evaluated. Theoretical and experimental results have been compared.

Similar content being viewed by others

References

V. A. Nelyub, “Method for assessing the chemical reaction between carbon fibre and epoxide binder,” Fibre Chem. 47 (1), 40–42 (2015).

V. A. Nelyub and A. A. Berlin, “A study of the chemical structure of the surface of carbon fibers before and after oxidation,” Polym. Sci., Ser. D 8 (3), 175–180 (2015).

G. V. Malysheva, E. Sh. Akhmetova, and Yu. Yu. Shimina, “Determination of phase transition temperatures of polymer binding agents by differential scanning calorimetry,” Polym. Sci., Ser. D 8 (1), 17–21 (2015).

G. V. Malysheva, E. S. Akhmetova, and A. N. Marycheva, “Estimation of glass transition temperature of polysulfone modified epoxy binders,” Glass Phys. Chem. 40 (5), 543–548 (2014).

A. S. Borodulin, “Plasticizers for epoxy adhesives and binders,” Polym. Sci., Ser. D 6 (1), 59–62 (2013).

N. I. Baurova, “Influence of nanostructured defects in carbon fibers and ribbons on sensor properties,” Polym. Sci., Ser. D 4 (3), 242–245 (2011).

A. S. Borodulin, “Polyester resins for production of goods from polymer composite materials by pressing methods,” Polym. Sci., Ser. D 6 (3), 269–270 (2013).

V. A. Nelyub, “Technology for producing prepregs,” Vse Mater., Entsikl. Sprav., No. 3, 12–17 (2013).

A. N. Muranov, G. V. Malysheva, V. A. Nelyub, I. A. Buyanov, I. V. Chudnov, and A. S. Borodulin, “Investigation of properties of polymeric composition materials abound a heterogeneous matrix,” Polym. Sci., Ser. D 6 (3), 256–259 (2013).

A. S. Borodulin, G. V. Malysheva, and I. K. Romanova, “Optimization of rheological properties of binders used in vacuum assisted resin transfer molding of fiberglass,” Polym. Sci., Ser. D 8 (4), 300–303 (2015).

G. V. Malysheva and I. R. Saifulin, “Methods for evaluating the content of the polymer matrix in the composite material,” Vse Mater., Entsikl. Sprav., No. 1, 2–5 (2014).

I. A. Aleksandrov, G. V. Malysheva, V. A. Nelyub, I. A. Buyanov, I. V. Chudnov, and A. S. Borodulin, “Investigation of fracture surfaces of CFRP produced by melting and solution technologies,” Vse Mater., Entsikl. Sprav., No. 3, 7–12 (2012).

I. L. Chebyshev, Dressmaking. Full Composition of Writings (Izd. Akad. Nauk SSSR, Moscow, 1951), Vol. 5 [in Russian].

A. Endruweit and P. Ermanni, “The in-plane permeability of sheared textiles. Experimental observations and a predictive conversion model,” in Composites Part A: Applied Science and Manufacturing (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Pyi Phyo Maung, G.V. Malysheva, S.A. Gusev, 2016, published in Vse Materialy, 2016, No. 5, pp. 2–6.

Rights and permissions

About this article

Cite this article

Maung, P.P., Malysheva, G.V. & Gusev, S.A. A study of the effect of network angle of fabrics on kinetics of impregnation upon molding of articles made from carbon plastics. Polym. Sci. Ser. D 9, 407–410 (2016). https://doi.org/10.1134/S1995421216040146

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421216040146