Abstract

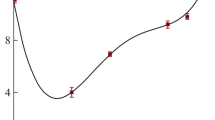

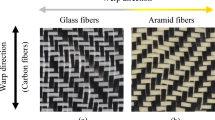

The results of experimental estimation of the drapability coefficients for glass, carbon, and organic fabrics are given. It is found that the smallest characteristics concerning drapability are for carbon fabrics, while the best are for organic ones. Comparison of different types of the weaving shows that the drapability of triaxial fabrics is higher than that of fabrics of plain and twill weave.

Similar content being viewed by others

References

G. V. Malysheva and Y. Y. Shimina, “Influence of preparation technology on carbon-fiber-composite component composition,” Fibre Chem. 46 (4), 237–240 (2014).

A. S. Borodulin, “Properties and characteristics of structures of the glass fibers used for the manufacture of GRP,” Materialovedenie, No. 7, 34–37 (2012).

V. A. Nelyub, “Estimation of adhesion between carbon fiber and epoxy binder,” Klei, Germetiki, Tekhnol., No. 7, 20–22 (2014).

V. M. Kuznetsov and G. E. Nekhoroshikh, “The use of carbon fiber reinforced plastics in the manufacture of toroidal pressure vessels,” Vse Mater., Entsikl. Sprav., No. 2, 32–36 (2015).

G. V. Malysheva, E. S. Akhmetova, and A. N. Marycheva, “Estimation of glass transition temperature of polysulfone-modified epoxy binders,” Glass Phys. Chem. 40 (5), 543–548 (2014).

N. I. Baurova and A. Y. Sergeev, “Structural studies of fracture patterns in adhesive joints after pullout testing,” Polym. Sci., Ser. D 7 (4), 298–302 (2014).

G. V. Malysheva, “Predicting the endurance of adhesive joints,” Polym. Sci., Ser. D 7 (2), 145–147 (2014).

N. I. Baurova, “Influence of nanostructured defect in carbon fibers and ribbons on sensor properties,” Polym. Sci., Ser. D 4 (3), 242–245 (2011).

L. P. Kobets, G. V. Malysheva, and A. S. Borodulin, “Rheological properties of the elastomeric binder system–discrete carbon fiber,” Materialovedenie, No. 5, pp. 47–51 (2015).

I. V. Chudnov, “Calculation of stress-strain state support of construction parts made of fiberglass,” Entsikl. Inzh.-Khim., No. 4, 32–36 (2012).

Abu Sakr Vadikh, E. A. Kirsanova, R. V. Maksimenko, and G. E. Makharashvili, “Changes in textile material properties under the influence of technological factors,” Dizain Tekhnol., No. 23, 83–86 (2011).

A. A. Kvasova and E. A. Kirsanova, “Methods of assessing the properties of materials to create a database for the design of garments of different price ranges,” Dizain Tekhnol., No. 43, 20–25 (2014).

E. O. Volkov, A. S. Razina, and G. E. Nekhoroshikh, “Development of the framework model of the deployed bulk modulus on the basis of the elastic elements of the polymer composite material,” Vse Mater., Entsikl. Sprav., No. 8, 31–33 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.V. Malysheva, M.S. Tumasova, E.S. Tepishkina, 2015, published in Vse Materialy. Entsiklopedicheskii Spravochnik, 2015, No. 10, pp. 8–13.

Rights and permissions

About this article

Cite this article

Malysheva, G.V., Tumasova, M.S. & Tepishkina, E.S. Evaluation of forming properties of fabrics from carbon, glass, and organic fibers. Polym. Sci. Ser. D 9, 223–227 (2016). https://doi.org/10.1134/S1995421216020143

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421216020143