Abstract

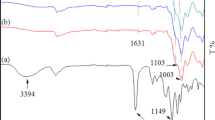

Nanocomposites attract the attention of researchers due to the increasing demand on materials having unique properties. Incorporation of nanoparticles into polymers considerably improves some materials properties such as thermal stability. In current study, PMMA/SiO2 hybrid nanocomposites including ungrafted and grafted silica nanoparticles have been prepared. The surfaces of SiO2 nanoparticles were grafted with 3-(methacryloyloxypropyl)trimethoxysilane (MPTS) and 3-(methacryloyloxypropyl)triethoxysilane (MPTES) by sol-gel technique. The structure, morphology and thermal properties of the obtained bulk materials were investigated by FTIR, SEM-EDX, TGA and DSC. Based on the studies of infrared spectroscopy, polymerization of MMA monomers was approved by following the intensity of acrylate group. Thermal characteristics of nanocomposite structures enhanced remarkably as SiO2 nanoparticles were introduced to the polymer matrix and glass transition temperature Tg value reached to the highest (166°C) for MPTES@20% SiO2-PMMA hybrid nanocomposite. According to SEM analysis, the most homogenous structure belonged to MPTES@20% SiO2-PMMA hybrid nanocomposite.

Similar content being viewed by others

REFERENCES

D. Abliz, Y. Duan, L. Steuernagel, L. Xie, D. Li, and G. Ziegmann, Polym. Compos. 21, 341 (2013).

M. H. Naveen, N. G. Gurudatt, and Y.-B. Shim, Appl. Mater. Today 9, 419 (2017).

M. Dziadek, E. Stodolak-Zych, and K. Cholewa-Kowalska, Mater. Sci. Eng., C 71, 1175 (2017).

L. Liu, D. Ye, R. Dong, D. Chen, S. Li, K. Cao, G. Cheng, S. Chen, and W. Huang, ACS Appl. Energy Mater. 3, 4068 (2020).

B. H. Patel and P. V. Joshi, J. Packag. Technol. Res. 4, 95 (2020).

H. Abbas, S. Iqbal, S. Ahmad, and N. Arfin, Mater. Res. Express 5 (8), 085312 (2018).

S. Rattan, P. Singhal, and A. L. Verma, Polym. Eng. Sci. 53, 2045 (2013).

T. Lin and Y. Zheng, Micro Nano Lett. 8, 217 (2013).

X. Song, X. Wang, H. Wang, W. Zhong, and Q. Du, Mater. Chem. Phys. 109, 143 (2008).

V. I. Bykov, K. L. Makovetskii, D. S. Popov, M. V. Bermeshev, T. A. Butenko, and Yu. A. Talyzenkov, Dokl. Chem. 439, 227 (2011).

P. Xu, H. Wang, R. Tong, Q. Du, and W. Zhong, Colloid Polym. Sci. 284, 755 (2006).

E. Arpac, S. Güven, Ş. Yılmaz, J. C. Schmidt, H. Schmidt, D. Mochizuki, and K. Osada, WO Patent No. WO/2009/115566 (2009).

P. Judeinstein and C. Sanchez, J. Mater. Chem. 6, 511 (1996).

B. M. Novak, Adv. Mater. 5, 422 (1993).

V. N. T. Satyanarayana Kuchibhatla, A.S. Karakoti, and S. Seal, JOM 57, 52 (2005).

M. Iijima and H. Kamiya, KONA Powder Part. J. 27, 119 (2009).

L. Guerrini, R. A. Alvarez-Puebla, and N. Pazos-Perez, Materials 11, 1154 (2018).

H. Heinz, C. Pramanik, O. Heinz, Y. Ding, R. K. Mishra, D. Marchon, R. J. Flatt, I. Estrela-Lopis, J. Llop, S. Moya, and R. F. Ziolo, Surf. Sci. Rep. 72, 1 (2017).

E. Yavuz, R. Erdem, E. Küçüksayan, E. Akarsu, and M. Akarsu, Fibers Polym. 22, 1274 (2021).

N. Wang, X. Wu, and C. S. Liu, Polymers 11, 979 (2019).

C. J. T. Landry, B. K. Coltrain, and B. K. Brady, Polymer 33, 1486 (1992).

C. Li, J. Wu, J. Zhao, D. Zhao, and Q. Fan, Eur. Polym. J. 40, 1807 (2004).

Y.-H. Hu, C.-Y. Chen, and C.-C. Wang, Polym. Degrad. Stab. 84, 545 (2004).

M. Salami-Kalajahi, V. Haddadi-Asl, S. Rahimi-Razin, F. Behboodi-Sadabad, H. Roghani-Mamaqani, and M. Najafi, Int. J. Polym. Mater. 62, 336 (2013).

W. Stöber, A. Fink, and E. Bohn, J. Colloid Interface Sci. 26, 62 (1968).

Y. Lin, L. Liu, D. Zhang, Y. Liu, A. Guan, G. Wu, Soft Matter 12, 8542 (2016).

Y. Yang and Y. Dan, Colloid Polym. Sci. 281, 794 (2003).

M. Chen, L. Wu, S. Zhou, and B. You, Macromolecules 37, 9613 (2004).

R. Y. Hong, H. P. Fu, Y. J. Zhang, L. Liu, J. Wang, H. Z. Li, and Y. Zheng, J. Appl. Polym. Sci. 105, 2176 (2007).

J.-M. Yeh, C.-J. Weng, W.-J. Liao, and Y.-W. Mau, Surf. Coat. Technol. 201, 1788 (2006).

Rd. S. Leão, S. L. D. de Moraes, K. A. S. Aquino, C. P. Isolan, B. Gd. S. Casado, and M. A. J. R. Montes, Int. J. Dent. 2018, 5743840 (2018).

A. R. Cho and S.-Y. Park, Opt. Mater. Express 5, 690 (2015).

M. L. Saladino, T. E. Motaung, A. S. Luyt, A. Spinella, G. Nasillo, and E. Caponetti, Polym. Degrad. Stab. 97, 452 (2012).

J. Coates, “Interpretation of Infrared Spectra, A Practical Approach,” in Encyclopedia of Analytical Chemistry: Applications, Theory and Instrumentation (Wiley, New York, 2006). https://doi.org/10.1002/9780470027318.a5606

P. J. Launer and B. Arkles, “Infrared Analysıs of Organosılıcon Compounds: Spectra-Structure Correlatıons,” in Silicon Compounds: Silanes and Silicones (Gelest, Inc Morrisville, PA, 2003), pp. 175‒178.

B. H. Stuart, Infrared Spectroscopy: Fundamentals and Applications (John Wiley and Sons Ltd, West Sussex, England, 2004), pp.123‒129.

Y. Lin, L. Liu, G. Xu, D. Zhang, A. Guan, and G. Wu, J. Phys. Chem. 119, 12956 (2015).

B. Arkles, J. R. Steinmetz, J. Zazyczny, and P. Mehta, J. Adhes. Sci. Technol. 6, 193 (1992).

T. Kashiwagi, A. Inaba, J. E. Brown, K. Hatada, T. Kitayama, and E. Masuda, Macromolecules 19, 2160 (1986).

J. Rychlý and J. Pavlinec, Polym. Degrad. Stab. 28, 1 (1990).

S. M. Lomakin, J. E. Brown, R. S. Breese, and M. R. Nyden, Polym. Degrad. Stab. 41, 229 (1993).

ACKNOWLEDGMENTS

Authors would like to thank to Prof. Dr. Turgay Seçkin at Chemistry Department of İnönü University for his technical support for TGA analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declared that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Emre Yavuz, Erdem, R. & Akarsu, E. Enhancing Glass Transition Temperature of Poly(methylmethacrylate) by Incorporating Methacrylate-Functional Silane Grafted SiO2 Nanoparticles. Polym. Sci. Ser. B 64, 546–552 (2022). https://doi.org/10.1134/S1560090422700191

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090422700191