Abstract

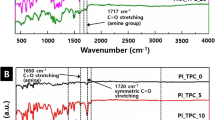

High heat resistant and stable dimensional PI films have been widely used in organic light emitting diode industry, therefore the comprehensive performance should be enhanced. The PI films of low CTE and high heat resistance were prepared with 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BPDA) and p-phenylenediamine (PDA) under different processing conditions. WAXD and FTIR were performed to characterize the microstructure of the films. DMA and TMA were conducted to investigate the mechanical and thermal properties of the films. The results showed that the density of the films increased and water absorption rate decreased with fabrication temperature as a result of the smectic structure. The smectic structure of the film attributed to the oriented polymer chains was observed in the DMA curves peaked at 470°C. The film would shrink at round the glass transition temperature as indicated by the TMA curves when it was prepared at relatively lower fabrication temperature, resulting in a larger CTE value compared with other prepared at high fabrication temperature. The 1% weight loss temperature increased with the fabrication temperature for the smectic structure. The tensile strength and elongation at break of the film increased with smectic density. The heat resistance and mechanical performance of bioriented films were the best among all the samples as the PI chains were stretched during the imidization process when all the edges of the film were fixed. The results obtained in this paper could offer practical and valuable references to optimization of processing parameters for the preparation of high performance PI films.

Similar content being viewed by others

REFERENCES

J. H. Kim, M. C. Choi, H. Kim, Y. Kim, J. H. Chang, M. Han, I. Kim, and C. S. Ha, J. Nanosci. Nanotechnol. 10, 388 (2010).

M. Auch, O. K. Soo, G. Ewald, and C. Soo-Jin, Thin Solid Films 417, 47 (2002).

H. Lim, W. J. Cho, C. S. Ha, S. Ando, Y. K. Kim, C. H. Park, and K. Lee, Adv. Mater. 14, 1275 (2002).

S. Han, Y. Li, F. Hao, H. Zhou, S. Qi, G. Tian, and D. Wu, Eur. Polym. J. 143, 110206 (2021).

C. Huang, S. Wang, H. Zhang, T. Li, S. Chen, C. Lai, and H. Hou, Eur. Polym. J. 42, 1099 (2006).

W. J. Bae, M. K. Kovalev, F. Kalinina, M. Kim, and C. Cho, Polymer 105, 124 (2016).

M. Hasegawa, Y. Hoshino, N. Katsura, and J. Ishii, Polymer 111, 91 (2017).

J. Seo, K. Cho, and H. Han, Polym. Degrad. Stab. 74, 133 (2001).

H. Wang, J. T. Ryu, C. Cao, and Y. Kwon, J. Nanosci. Nanotechnol. 8, 4846 (2008).

J. S. Park, T. W. Kim, D. Stryakhilev, J. S. Lee, S. G. An, Y. S. Pyo, D. B. Lee, Y. G. Mo, D. U. Jin, and H. K. Chung, Appl. Phys. Lett. 95, 81462 (2009).

T. Miwa, Y. Okabe, and M. Ishida, Polymers 38, 4945 (1997).

W. Yang, F. Liu, J. Zhang, E. Zhang, X. Qiu, and X. Ji, Eur. Polym. J. 96, 429 (2017).

D. J. Liaw, K. L. Wang, Y. C. Huang, K. R. Lee, and C. S. Ha, Prog. Polym. Sci. 37, 907 (2012).

Y. Lu, and M. Zhan, J. Polym. Sci., Part B: Polym. Phys. 43, 2154 (2005).

M. B. Saeed and M. S. Zhan, Eur. Polym. J. 42, 1844 (2006).

J. Ishii, N. Shimizu, N. Ishihara, Y. Ikeda, N. Sensui, T. Matano, and M. Hasegawa, Eur. Polym. J. 46, 69 (2010).

Y. Shoji, R. Ishige, T. Higashihara, J. Watanabe, and M. Ueda, Macromolecules 43, 703 (2010).

Funding

This work was sponsored by national natural science foundation of China under grant 51973056 and 52173034, Hunan provincial project of science and technology under grant 2020NK2035, 2021JJ50031 and 2021JJ50009, scientific research projects of Hunan provincial department of education under grant 18A258 and 18C0524, the science and technology innovation program of Hunan province under grant 2021RC4065.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

CONFLICT OF INTEREST

The authors declare that they have no conflicts of interest.

CONFLICT OF INTEREST

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Peng Jun, Jin, W., Jun, Y. et al. Effect of Processing Temperature on the Thermal and Mechanical Properties of BPDA–PDA. Polym. Sci. Ser. B 64, 518–525 (2022). https://doi.org/10.1134/S1560090422700105

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090422700105